Durable and High-Performance Aramid Fiber: Everything You Need to Know

By:Admin

One of the leading companies in the production and development of Aramid Fiber is {}, a global leader in advanced materials and specialty fibers. The company has been at the forefront of innovation in the field of high-performance materials, and their Aramid Fiber products have been widely adopted in various industries around the world. With a strong focus on research and development, {} continues to push the boundaries of what is possible with Aramid Fiber, constantly seeking new and improved ways to enhance its properties and performance.

In the aerospace industry, Aramid Fiber has become a key material for the construction of aircraft and spacecraft. Its high tensile strength and resistance to heat make it an ideal choice for a wide range of applications, including structural components, insulation, and protective gear. With the demand for lightweight and fuel-efficient aircraft, Aramid Fiber has played a crucial role in helping manufacturers achieve their goals while ensuring the safety and performance of their products.

In the military sector, the exceptional properties of Aramid Fiber have made it a preferred material for ballistic protection and armor systems. Its high resistance to impact and penetration, coupled with its lightweight nature, have made it an essential component in the development of advanced body armor, helmets, and vehicle protection systems. As military operations become increasingly complex and challenging, the need for reliable and effective protection has driven the demand for Aramid Fiber-based solutions.

The automotive industry has also benefited from the use of Aramid Fiber in various applications. Its high strength and heat resistance have made it a valuable material for components such as brake pads, clutches, and tires. In addition, Aramid Fiber-reinforced composites have been used to improve the structural integrity and safety features of vehicles, contributing to the overall performance and longevity of automotive products.

In the industrial sector, Aramid Fiber has found applications in a wide range of products, including conveyor belts, hoses, and cables. Its ability to withstand high temperatures and mechanical stress makes it an ideal choice for demanding industrial environments. With its low flammability and resistance to chemicals, Aramid Fiber has proven to be a reliable and durable material for a variety of industrial applications.

Through its continuous research and development efforts, {} has been able to enhance the properties of Aramid Fiber, making it even more versatile and adaptable to various industry needs. By leveraging its expertise and capabilities, the company has been able to offer innovative solutions that address the evolving demands of its customers. With a strong commitment to quality and performance, {} has established itself as a trusted partner for businesses looking to leverage the benefits of Aramid Fiber in their products and applications.

As the demand for high-performance materials continues to grow, Aramid Fiber is expected to play an increasingly important role in shaping the future of various industries. With the expertise and capabilities of companies like {}, the potential for further advancements and innovations in the field of Aramid Fiber is vast, offering promising opportunities for businesses and industries looking to enhance the performance, safety, and sustainability of their products and applications.

Company News & Blog

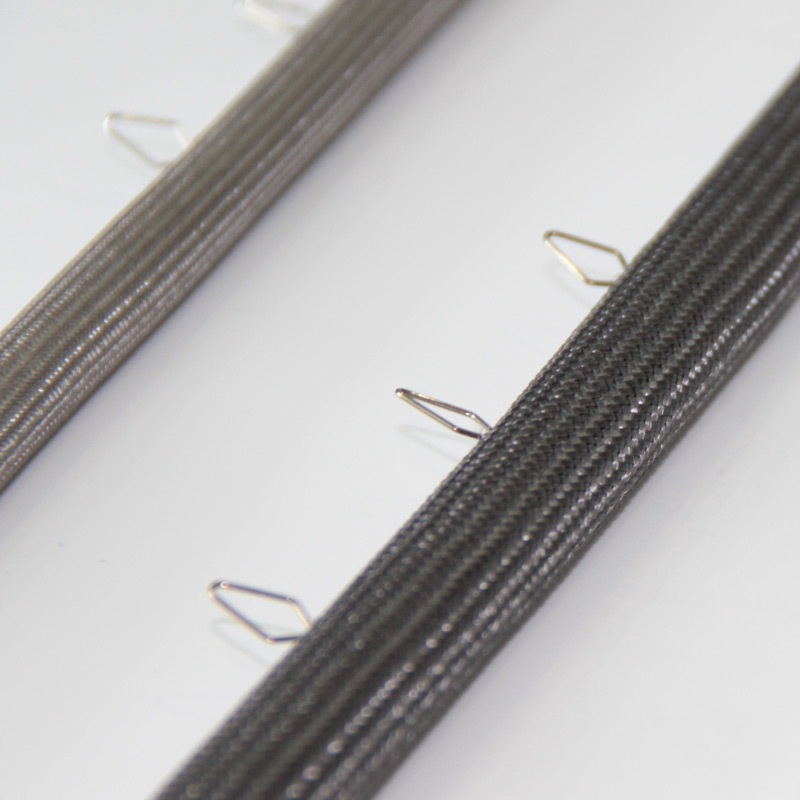

Effective Anti Rodent Sleeve for Rodent Control

Introducing the Revolutionary Anti Rodent Sleeve: A Game-Changer in Pest ControlIn recent years, rodent infestations have become a growing concern for homeowners and business owners alike. These pesky creatures not only cause damage to property but also pose serious health risks. Traditional pest control methods such as traps and poisons can be effective, but they often come with their own set of drawbacks. Fortunately, a new solution has emerged in the form of the innovative Anti Rodent Sleeve, a game-changer in the fight against rodents.The Anti Rodent Sleeve is a revolutionary product that effectively protects cables, wires, and other vulnerable areas from rodent damage. Made from a durable and flexible material, the sleeve is designed to withstand chewing and gnawing, making it an ideal solution for preventing rodent infestations in homes, businesses, and agricultural settings.One of the key features of the Anti Rodent Sleeve is its easy installation process. It can be quickly and easily applied to cables and wires of all sizes, providing a hassle-free and long-lasting solution to rodent damage. This makes it a cost-effective and efficient way to protect valuable equipment and infrastructure from the destructive behavior of rodents.The company behind this groundbreaking product, has been a leader in the pest control industry for over 20 years. Known for their commitment to innovation and quality, they have developed a range of highly effective pest control solutions that are trusted by homeowners, businesses, and professionals worldwide.The Anti Rodent Sleeve is the latest addition to their growing product line, and it has already garnered widespread attention for its exceptional performance and durability. With a strong focus on research and development, the company has leveraged its expertise to create a product that addresses a critical need in the pest control market.What sets the Anti Rodent Sleeve apart from other products on the market is its superior design and construction. The material used in the sleeve is not only resistant to rodent damage but also weatherproof, making it suitable for both indoor and outdoor use. This versatility makes it an ideal choice for a wide range of applications, from protecting household appliances to securing electrical wiring in agricultural settings.Furthermore, the Anti Rodent Sleeve is environmentally friendly and safe for use around children and pets, making it an attractive option for homeowners who are looking for a non-toxic and sustainable pest control solution. Its effectiveness in preventing rodent damage has earned it high praise from customers and industry professionals alike, establishing it as a game-changer in the fight against pests.In addition to its exceptional performance, the Anti Rodent Sleeve is backed by the company's renowned customer service and technical support. Their team of experts is dedicated to helping customers find the best pest control solutions for their specific needs and is always available to answer questions and provide guidance on product selection and usage.As rodent infestations continue to pose a significant threat to homes, businesses, and agricultural operations, the Anti Rodent Sleeve offers a much-needed solution that is both effective and sustainable. With its innovative design, durable construction, and proven performance, it is poised to become a staple in the pest control industry and a trusted ally in the ongoing battle against rodents.In conclusion, the Anti Rodent Sleeve represents a significant advancement in pest control technology, providing a practical and reliable solution to the widespread problem of rodent infestations. With its exceptional performance, ease of use, and environmental friendliness, it has quickly become a go-to choice for homeowners, businesses, and professionals seeking a long-term solution to rodent damage. As the company continues to lead the way in developing innovative pest control solutions, customers can rest assured that they are investing in a product that delivers real results and lasting protection against pests.

Discover the Benefits of Fiberglass Sleeving for Electrical Applications

[Company Introduction][Company Name] is a leading manufacturer and supplier of high-quality industrial materials. With over [number] years of experience in the industry, we strive to provide our customers with innovative solutions and top-notch products.Our commitment to excellence and customer satisfaction has earned us the trust and loyalty of businesses worldwide. We take pride in our extensive range of products, which includes [product categories]. From electrical insulation materials to mechanical protection solutions, we cater to various industries, meeting their diverse needs and requirements.Our state-of-the-art manufacturing facility, equipped with cutting-edge technology and skilled professionals, ensures that our products are of the highest standard. With a strong emphasis on quality control measures, we conduct rigorous testing at every stage of the production process to ensure optimal performance and reliability.At [Company Name], we believe in sustainable practices and responsible manufacturing. We are committed to minimizing our environmental impact and continuously improving our processes to adopt greener alternatives. Our dedication to sustainability extends to the materials we use, including our range of Fibreglass Sleeving.[Introduction to Fibreglass Sleeving]Fibreglass Sleeving is a versatile and highly durable electrical insulation material that finds applications across various industries. Designed to safeguard electrical components from heat, chemicals, and abrasions, this sleeving provides dependable protection in demanding environments.Key Features of Fibreglass Sleeving:1. High Temperature Resistance: Fibreglass Sleeving is known for its exceptional resistance to high temperatures. This makes it suitable for use in applications where prolonged exposure to heat is expected, such as in motors, transformers, and generators.2. Electrical Insulation: The insulating properties of Fibreglass Sleeving make it ideal for electrical applications, where it effectively prevents current leakage and enhances safety. It ensures the efficient functioning of electrical systems, minimizing the risk of shorts and malfunctions.3. Chemical Resistance: Fibreglass Sleeving demonstrates excellent resistance to a wide range of chemicals, making it an ideal choice for industries that deal with corrosive substances. It provides a protective layer that shields electrical components from chemical damage, extending their lifespan.4. Mechanical Protection: The robust nature of Fibreglass Sleeving offers mechanical protection to wires and cables. It resists wear and tear caused by abrasion, thereby ensuring the longevity of the components and enhancing their reliability.5. Flexibility and Expandability: Fibreglass Sleeving is available in various sizes and configurations, allowing for easy installation and fitting onto different wire diameters. Its expandability ensures a snug fit, offering excellent coverage and protection.Applications of Fibreglass Sleeving:1. Electrical Equipment: Fibreglass Sleeving is widely used in electrical equipment, including motors, generators, transformers, and coils. It ensures insulation, protection, and heat resistance in these critical components.2. Automotive Industry: The automotive industry heavily relies on Fibreglass Sleeving for wire harnessing and insulation purposes. It provides a reliable barrier against heat, abrasion, and chemicals, thereby enhancing the performance and safety of vehicles.3. Electronic Appliances: Fibreglass Sleeving is utilized in electronic appliances such as kitchen appliances, televisions, and computers. It safeguards wiring connections and electrical components from heat and abrasions caused by regular usage.4. Industrial Applications: Various industrial sectors, such as aerospace, manufacturing, and telecommunications, benefit from Fibreglass Sleeving. Its high temperature resistance, electrical insulation, and durability make it a preferred choice for protecting wires and cables in these demanding environments.In conclusion, Fibreglass Sleeving offered by [Company Name] is a reliable and efficient choice for electrical insulation and mechanical protection. With its exceptional performance under high temperatures, chemical resistance, and flexibility, this sleeving ensures the long-term reliability of electrical components in various industries. At [Company Name], we strive to provide our customers with superior products backed by our dedication to quality and sustainability.

A New Expandable Sleeve Technology Promises More Efficient Cable Management

Emi: The Pioneering Expandable Sleeve Revolutionizing Industrial PackagingIn the fast-paced world of industrial packaging, companies are constantly on the lookout for innovative solutions that can increase efficiency, reduce costs, and improve overall productivity. Emi, a trailblazer in the industry, has set itself apart with its groundbreaking expandable sleeve technology. With its superior performance and versatility, Emi's expandable sleeves have become an indispensable tool for various sectors, from automotive to food and beverage.Emi's expandable sleeves are designed to accommodate a wide range of products, providing a secure and customized fit that ensures maximum protection during transportation and storage. With the ability to seamlessly expand or contract, these sleeves can adapt to the dimensions of different items, eliminating the need for multiple packaging solutions. This not only saves time but also reduces material waste, making it an environmentally-friendly choice for businesses.One of the key advantages of Emi's expandable sleeves lies in their durability. Constructed using high-quality materials and advanced manufacturing techniques, these sleeves are built to withstand the rigors of various industry settings. Whether it's exposure to extreme temperatures or rough handling during transit, Emi's expandable sleeves provide reliable protection, keeping products intact and damage-free.Moreover, Emi's expandable sleeves offer excellent flexibility, allowing them to conform to irregularly shaped items effortlessly. This versatility is particularly beneficial for companies with unique packaging requirements. Whether it's a delicate electronic component or an odd-shaped automotive part, Emi's expandable sleeves provide a snug fit that eliminates the risk of damage during handling and transportation.In addition to their protective qualities, Emi's expandable sleeves boast excellent product visibility. Their transparency allows businesses to easily identify and inspect packaged items without the need for unpacking, reducing the chances of errors and optimizing operational efficiency. This feature is especially valuable in industries where traceability and quality control are of utmost importance.Emi is committed to not only providing superior packaging solutions but also fostering sustainability. The company recognizes the importance of eco-friendly practices in today's world and ensures that its expandable sleeves are recyclable and made from environmentally conscious materials. By championing sustainable packaging, Emi is aiding businesses in their efforts to reduce their carbon footprint and embrace greener alternatives.With a global mindset, Emi has successfully collaborated with companies across continents, delivering its innovative expandable sleeves to clients worldwide. This has established the company's reputation as a trusted partner when it comes to industrial packaging solutions. By prioritizing customer satisfaction and continuously improving its products, Emi has earned the loyalty of a diverse range of industries, including electronics, pharmaceuticals, and consumer goods.Emi's commitment to innovation and customer-focused solutions has led to numerous accolades and recognition within the industry. Notably, the company was recently awarded the prestigious Packaging Innovation Award for its expandable sleeve technology. This recognition underscores Emi's dedication to pushing the boundaries of industrial packaging and providing game-changing solutions for its clients.As the global industrial packaging market continues to expand, Emi remains at the forefront, spearheading new advancements and setting industry standards. With its pioneering expandable sleeves, the company is revolutionizing the way products are protected and transported. By offering durability, flexibility, and sustainability, Emi's expandable sleeves have become a cornerstone of efficient packaging solutions across various industries, confirming the company's position as a true industry leader.

New Membrane Support Technology Set to Revolutionize Industry

Membrane Support, a leading provider of innovative solutions for the water and wastewater treatment industry, has recently launched a new range of cutting-edge membrane support products designed to enhance the performance and efficiency of membrane filtration systems.Founded in 2005, Membrane Support has quickly established itself as a key player in the water treatment industry, known for its commitment to developing high-quality, reliable products that address the evolving needs of the market. The company's extensive expertise in membrane technology and filtration processes has enabled it to create a diverse portfolio of solutions that cater to a wide range of applications, from industrial and municipal water treatment to desalination and wastewater recycling.The latest addition to Membrane Support's product lineup includes a variety of membrane support products that have been engineered to deliver superior performance and durability. These products are specifically designed to provide optimal support for membrane filtration systems, ensuring their long-term efficiency and longevity. The advanced materials and construction techniques used in the manufacturing process result in products that are highly resistant to fouling, scaling, and other common issues that can compromise the performance of membrane systems.One of the key features of Membrane Support's new range of products is their versatility, with solutions available for a wide range of membrane configurations, including spiral-wound, hollow fiber, and tubular membranes. This flexibility enables customers to find the perfect fit for their specific requirements, whether they are operating small-scale residential systems or large-scale industrial facilities.In addition to offering superior performance, Membrane Support's products also prioritize ease of installation and maintenance, reducing downtime and overall operational costs. The company's dedication to providing comprehensive support and technical expertise ensures that customers can rely on their products to deliver consistent results, backed by responsive and knowledgeable customer service.Furthermore, Membrane Support is committed to sustainability and environmental responsibility, with its products designed to contribute to the efficient use of water resources and the reduction of energy consumption. By optimizing the performance of membrane filtration systems, Membrane Support helps its customers minimize their environmental impact while maximizing the effectiveness of their water treatment processes.The launch of the new range of membrane support products marks a significant milestone for Membrane Support, further solidifying its position as a leading provider of innovative solutions for the water treatment industry. Leveraging its extensive experience and technical capabilities, the company continues to push the boundaries of membrane technology, delivering solutions that meet the evolving needs of the market and contribute to the overall improvement of water treatment processes worldwide.With its unwavering commitment to quality, performance, and customer satisfaction, Membrane Support is poised to make a lasting impact in the water and wastewater treatment industry, setting new standards for membrane support solutions and driving advancements in the field of membrane technology. As the company continues to expand its product offerings and reach new markets, it remains dedicated to its core values of innovation, reliability, and sustainability, shaping the future of water treatment with its groundbreaking solutions.

Protect Your Wires with High-Temperature Sleeving

High Temperature Wire Sleeving: The Future of Protection for Electrical ComponentsElectrical components are fragile devices that are easily susceptible to damage due to environmental factors. Temperature, humidity, and physical contact are some of the common factors that can damage these parts. That's why a protective covering is necessary to shield them from these factors. High-temperature wire sleeving is a new and efficient method of protecting electrical components that is setting new standards in the industry.One such company that is revolutionizing the sleeve industry is Company X. Company X was established in 2000, and since then, it has been providing customers with high-quality sleeving products that cater to different industries ranging from aerospace, automotive, telecommunications, and military. The company is committed to offering superior products that protect and safeguard electrical components, making it a leader in its industry.The company produces a wide range of high-temperature wire sleeving products to meet different industrial needs. These include products such as fiberglass braided sleeving, silicone coated fiber sleeves, and high-temperature ceramic sleeving. These sleeving products have different properties that allow them to function well in high-temperature environments, protecting wires from the surrounding heat and potential sources of damage.One of the key benefits of high-temperature wire sleeving is its heat-resistant properties. The sleeves are efficient in protecting electrical wires from the damage caused by high temperatures. Electrical wires are known to expose themselves to high temperatures, especially when they transmit high levels of power or run for extended periods. These high temperatures can lead to melting of the wires, corrosion, and degradation of the insulation material leading to a short circuit. High-temperature wire sleeving acts as a barrier, preventing these damaging effects of high temperatures.In addition to their heat-resistant properties, these high-temperature sleeves also provide protection from other environmental factors. For instance, they are waterproof and resistant to moisture. This is particularly important in industrial settings that may expose wires to water damage. The sleeving also protects electrical wires from physical contact, which can lead to breakage, deformation or damage to the insulation material.High-temperature wire sleeving also serves as an excellent insulator. The material used in making the sleeving has excellent insulating properties, preventing current leaks and electrical faults. Insulation also prevents electrical noise from propagating to other parts of the electrical system, which can interfere with the system's performance.Company X's sleeving solutions are designed to cater to the diverse industrial needs of its customers. The company produces custom sizes that are tailored to fit specific types of wires used in particular industries, ensuring that each sleeving piece offers optimum protection and performance.Another significant advantage of high-temperature wire sleeving is its durability. The protective sleeving is made of high-quality materials that are resistant to wear and tear, making them long-lasting. The sleeves can withstand environmental factors such as vibration, corrosion, and physical contact, maintaining their protective properties for an extended period.In conclusion, high-temperature wire sleeving is quickly becoming the go-to solution for protecting electrical components in the industrial sector. Advanced technology and superior materials have enabled Company X to produce high-quality sleeving products that are durable, resistant to environmental damage, and efficient in safeguarding electrical wires from high temperatures. These protective sleeves will continue being a valuable investment for industrial companies seeking reliable, long-lasting, and efficient protection of their electrical components. With the continued advancement of technology, the future of high-temperature wire sleeving looks bright, and companies like Company X will continue to spearhead its development and production.For more information about Company X and its products, visit their website or contact them directly.

Durable Nylon Sleeving for Cable and Wire Management - A Practical Solution for Protection and Organization

Nylon Sleeving - Your Ultimate Solution for Cable ProtectionIn today's fast-paced world, the demand for efficient and reliable cable protection solutions is higher than ever. With the rapid advancements in technology, the need to protect delicate cables and wires from potential damage has become increasingly critical. Fortunately, advances in materials science and engineering have given rise to a wide variety of cable protection options, among which Nylon Sleeving has emerged as a standout solution, offering unparalleled durability and versatility.Nylon Sleeving, also known as braided sleeving, is a flexible and abrasion-resistant cable protection solution that is widely used in a wide range of industries, including automotive, aerospace, marine, and electronics. Its unique blend of properties makes it the ideal choice for protecting cables and wires from damage, wear, and exposure to harsh environments.One of the key players in the Nylon Sleeving market is [Company Name]. With a strong focus on innovation and quality, [Company Name] has been at the forefront of developing high-performance Nylon Sleeving solutions that meet the diverse needs of its customers. By leveraging its extensive expertise and state-of-the-art manufacturing capabilities, [Company Name] has established itself as a trusted provider of Nylon Sleeving products that offer exceptional performance and reliability.[Company Name] has a wide range of Nylon Sleeving products that cater to various applications and requirements. Whether it's protection from abrasion, chemicals, or extreme temperatures, [Company Name] has a solution to meet the most demanding needs. Additionally, [Company Name] offers customization options, allowing customers to get Nylon Sleeving solutions tailored to their specific needs.One of the key advantages of Nylon Sleeving from [Company Name] is its exceptional durability. Made from high-quality nylon fibers, the sleeving is designed to withstand the rigors of daily use, ensuring long-lasting protection for cables and wires. Its flexible and expandable nature makes it easy to install and adapt to different cable configurations, making it an ideal choice for complex wiring setups.Furthermore, Nylon Sleeving from [Company Name] provides excellent resistance to abrasion and mechanical damage. This is particularly important in applications where cables are exposed to friction or rough handling. By effectively shielding cables from wear and tear, Nylon Sleeving helps extend the lifespan of cables, reducing the need for costly replacements and repairs.In addition to its durability and protective properties, Nylon Sleeving from [Company Name] also offers excellent resistance to chemicals and solvents. This makes it well-suited for use in industries where exposure to harsh chemicals is a common occurrence, such as automotive manufacturing, petrochemicals, and industrial processing. The sleeving's ability to maintain its integrity in such environments ensures the continued integrity of the cables it protects.Another noteworthy feature of Nylon Sleeving from [Company Name] is its ability to provide thermal protection. Whether it's exposure to high temperatures in automotive engine compartments or extreme cold in aerospace applications, the sleeving effectively insulates cables from thermal extremes, helping to maintain their performance and reliability.Furthermore, [Company Name] takes pride in its commitment to sustainability and eco-friendly practices. The Nylon Sleeving products from [Company Name] are manufactured to high environmental standards, utilizing processes that minimize waste and energy consumption. Additionally, the company is dedicated to developing recyclable and biodegradable materials for its sleeving solutions, contributing to a greener and more sustainable future.With its unwavering dedication to quality and innovation, [Company Name] continues to set the benchmark for Nylon Sleeving solutions. As the demand for reliable cable protection solutions continues to grow, [Company Name] remains at the forefront, offering cutting-edge products that deliver exceptional performance and value to its customers.In conclusion, Nylon Sleeving has emerged as a versatile and effective solution for protecting cables and wires from damage and wear. With [Company Name] leading the way with its high-quality and innovative products, the future of cable protection looks brighter than ever. Whether it's in automotive, aerospace, marine, or electronics, Nylon Sleeving from [Company Name] stands as the ultimate choice for ensuring the long-term integrity and performance of cables and wires.

Durable and Versatile Polyester Sleeving for Various Applications

Polyester Sleeving: A Durable Solution for Wire and Cable ProtectionIn the world of electrical engineering and cable management, finding durable and reliable solutions for protecting wires and cables is crucial. One such solution that has been gaining popularity in recent years is Polyester Sleeving. Known for its exceptional strength, flexibility, and resistance to abrasion, Polyester Sleeving has become a go-to choice for protecting and organizing wires and cables in a variety of applications.Polyester Sleeving, which is offered by a well-known company in the industry, {Company Name}, is a versatile, cost-effective solution that provides excellent protection for wires and cables in a wide range of environments. This sleeving is made from high-quality polyester materials, which are known for their durability and flexibility. The sleeving is designed to withstand the rigors of everyday use, making it an ideal choice for applications where wires and cables are subject to frequent movement and wear.One of the key benefits of Polyester Sleeving is its ability to provide excellent protection against abrasion and wear. This is particularly important in applications where wires and cables are exposed to harsh conditions, such as in industrial settings or outdoor environments. The sleeving acts as a protective barrier, shielding the wires and cables from damage and extending their lifespan. This can ultimately help to reduce maintenance and replacement costs, making Polyester Sleeving a cost-effective choice for businesses and organizations.In addition to its durability, Polyester Sleeving is also highly flexible, allowing for easy installation and maneuverability. This flexibility makes it easy to route and organize wires and cables in tight spaces, without sacrificing protection. As a result, Polyester Sleeving is an ideal choice for applications where space is limited, such as in automotive or aerospace industries.Furthermore, Polyester Sleeving is resistant to chemicals and oils, making it suitable for use in a wide range of industrial and commercial settings. Its resistance to these substances ensures that the sleeving will maintain its integrity and protection even in the presence of potentially damaging fluids, ensuring the continued safety and functionality of the wires and cables it encases.The company, {Company Name}, offers a wide range of Polyester Sleeving options to meet the specific needs of different applications. With various sizes, colors, and configurations available, customers can easily find the right sleeving to suit their requirements. Additionally, {Company Name} prides itself on providing exceptional customer service and technical support, ensuring that customers receive the guidance they need to select and install the most suitable Polyester Sleeving for their specific applications.As the demand for reliable wire and cable protection solutions continues to grow, Polyester Sleeving has emerged as a top choice for engineers, electricians, and other professionals in the industry. Its combination of durability, flexibility, and chemical resistance makes it a versatile and practical option for a wide range of applications. Backed by the expertise and support of {Company Name}, customers can have confidence in the quality and performance of Polyester Sleeving.In conclusion, Polyester Sleeving offered by {Company Name} is a durable and reliable solution for protecting and organizing wires and cables in a variety of applications. Its exceptional strength, flexibility, and resistance to abrasion make it a practical choice for industries where wire and cable protection is crucial. With a wide range of options available and expert support from {Company Name}, customers can trust in the performance and reliability of Polyester Sleeving for their specific needs.

Durable and Flexible Braided Nylon Wire Sleeving for Protection and Organization

Braided nylon wire sleeving is a key component in various industries where protection of wires and cables is of paramount importance. This type of sleeving is known for its durability, flexibility, and resistance to abrasion and chemicals, making it an ideal choice for a wide range of applications.One company that has been making a significant impact in the field of braided nylon wire sleeving is {}. With a focus on quality and innovation, they have become a trusted name in the industry.Established in [year], {} has been at the forefront of developing advanced solutions for wire and cable protection. They have a team of skilled engineers and technicians who are dedicated to creating products that meet the highest standards of performance and reliability. Their commitment to quality and customer satisfaction has helped them build a strong reputation in the market.One of the key products that {} specializes in is braided nylon wire sleeving. This sleeving is designed to provide protection and insulation for wires and cables in demanding environments. It is commonly used in industries such as automotive, aerospace, marine, and electronics, where the integrity of wiring systems is critical.The braided construction of this sleeving allows for flexibility and expandability, making it easy to install and maneuver around tight spaces. Additionally, the nylon material provides excellent resistance to abrasion, oil, and chemicals, ensuring long-lasting protection for the wires and cables it covers.{} takes pride in its ability to customize braided nylon wire sleeving to meet the specific requirements of their customers. Whether it's a particular size, color, or special performance characteristics, they have the expertise to develop a solution that fits the unique needs of each application. This flexibility has made them a preferred partner for companies looking for tailored wire protection solutions.In addition to braided nylon wire sleeving, {} offers a comprehensive range of wire and cable protection products. This includes expandable mesh sleeving, heat shrink tubing, cable ties, and accessories. Their diverse product portfolio allows customers to find all the necessary components for their wire management needs in one place, streamlining the sourcing process and ensuring compatibility and performance across the board.The company also places a strong emphasis on environmental sustainability and compliance with industry standards. Their products are designed to be RoHS compliant and meet various other regulatory requirements. {} is committed to reducing its environmental impact and contributing to the development of greener technologies and practices within the wire and cable management industry.Furthermore, {} has a strong focus on customer service and support. Their team of professionals works closely with customers to understand their specific needs and provide expert guidance and assistance throughout the entire process, from product selection to installation. This dedication to customer satisfaction has earned them a loyal and satisfied customer base.Looking ahead, {} is poised to continue its leadership in the field of wire and cable protection. With a strong focus on innovation, quality, and customer service, they are well-positioned to meet the evolving needs of their customers and the industry as a whole. As technology continues to advance and industries become more demanding, the importance of reliable wire and cable protection will only increase, making companies like {} invaluable partners in ensuring the integrity and performance of critical wiring systems.

Discover the Benefits of Expandable Cable Sleeving: An Essential Solution for Organizing and Protecting Cables

Title: Cutting-Edge Expandable Cable Sleeving Revolutionizes Cable ManagementIntroduction:In the constantly evolving world of technology, innovation plays a vital role in enhancing efficiency and productivity. One such breakthrough that promises to simplify cable management is the advanced Expandable Cable Sleeving developed by a leading company in the industry. With its exceptional qualities and versatility, this cutting-edge solution is set to revolutionize cable organization for various applications.I. Understanding the Expandable Cable SleevingThe Expandable Cable Sleeving is a highly flexible and durable material designed to encase cables, wires, and hoses. It is engineered to provide excellent protection against environmental factors such as abrasion, heat, chemical exposure, and electromagnetic interference (EMI). This technology ensures the safe and optimal performance of cables while maintaining a neat and organized appearance.II. Key Features and Benefitsa. High Expandability: The unique design of this cable sleeving enables it to expand up to four times its original diameter, making it adaptable to cables of varying sizes. This expandability facilitates easy installation and removal, eliminating the need for cutting or disassembling the cables.b. Superior Protection: The Expandable Cable Sleeving acts as a shield, safeguarding cables from potential damage caused by external impacts, including abrasion, cuts, dust, and moisture. It also provides insulation against high temperatures and protects against EMI, ensuring uninterrupted data transmission.c. Flexibility and Ease of Use: The material's exceptional flexibility allows for simple and hassle-free cable routing, even in tight spaces or complex configurations. The sleeving can effortlessly accommodate bends, twists, and turns without compromising cable integrity.d. Aesthetically Pleasing: In addition to its practical functionalities, this cable sleeving enhances the overall appearance of cable systems. It neatly groups and conceals multiple cables, creating a clean and organized look that also improves safety by reducing the risk of tripping or accidental disconnection.e. Maintenance and Durability: Made from high-quality materials, the Expandable Cable Sleeving exhibits remarkable durability, ensuring long-lasting protection for cables. Its resistance to oils, chemicals, and UV rays makes it suitable for a wide range of industrial applications, including automotive, aerospace, telecommunications, and home electronics.III. Applications and Market PotentialThe Expandable Cable Sleeving has vast applications across various sectors. In the automotive industry, it provides efficient protection for wiring harnesses, preventing damage from engine vibrations and harsh environmental conditions. In aerospace, this sleeving ensures the safe transmission of vital signals and power supply throughout complex aircraft systems. It also finds application in data centers, telecommunications networks, robotics, and audio/video installations.As the demand for cable management solutions escalates with the growing complexity of digital infrastructures, the potential market for this innovative product is substantial. With its reputation for providing cutting-edge solutions and a strong foothold in the industry, the company is poised to capture a significant share in this expanding market.IV. ConclusionThe all-new Expandable Cable Sleeving presents a groundbreaking solution that promises to revolutionize cable management. With its exceptional characteristics, including adaptability, protection, aesthetics, ease of use, and durability, this product ensures safe and efficient cable organization across various industries. As technology continues to advance, the flexibility and reliability of this cable sleeving will play a crucial role in keeping systems functioning optimally, establishing it as an indispensable tool for cable management.

High-Quality Electrical Wire Fiberglass Insulation Sleeving for Maximum Protection

The use of electrical wire fiberglass insulation sleeving has become increasingly popular in the electrical industry due to its high-quality insulation properties, durability, and flexibility. This type of sleeving is commonly used to protect wires and cables from environmental and mechanical damage, as well as provide an extra layer of insulation to prevent electrical shock or fire hazards.{Company Name} has been at the forefront of producing high-performance electrical wire fiberglass insulation sleeving for over two decades. With a strong focus on research and development, the company has continually improved its products to meet the ever-changing demands of the electrical industry. Their electrical wire fiberglass insulation sleeving is designed to provide reliable insulation in a wide range of temperatures, making it suitable for use in various applications such as automotive, aerospace, electronics, and industrial equipment. The sleeving is manufactured using high-quality fiberglass materials that are resistant to heat, chemicals, and abrasion, ensuring the long-term performance and safety of electrical components.In addition to its insulation properties, {Company Name}'s electrical wire fiberglass insulation sleeving is also highly flexible, allowing for easy installation and maintenance. The sleeving can be easily cut to size and bent around tight corners without compromising its integrity, making it a cost-effective solution for protecting and insulating electrical wiring in confined spaces.Furthermore, {Company Name} is committed to sustainability and environmental responsibility in its manufacturing processes. The company utilizes advanced technologies to minimize waste and emissions, and all of its products comply with international environmental regulations and standards. This dedication to sustainability has earned {Company Name} a reputation for being an environmentally conscious and socially responsible manufacturer in the electrical industry.As the demand for high-quality electrical wire insulation continues to grow, {Company Name} remains dedicated to meeting the needs of its customers with innovative and reliable products. With a strong emphasis on quality control and customer satisfaction, the company has built a loyal customer base that trusts in the performance and reliability of its electrical wire fiberglass insulation sleeving.In conclusion, {Company Name} is a leading manufacturer of electrical wire fiberglass insulation sleeving, offering a wide range of high-performance products designed to meet the stringent requirements of the electrical industry. With a focus on quality, flexibility, and sustainability, the company has positioned itself as a trusted and reliable supplier of electrical insulation solutions for a variety of applications. As the industry continues to evolve, {Company Name} is poised to remain at the forefront of innovation and excellence in electrical wire insulation technology.