Everything You Need to Know About Heat Shrinkable Sleeves

By:Admin

With over [number of years] years of experience in the industry, [Company Name] has established itself as a trusted provider of high-quality heat shrinkable products, catering to a wide range of applications across different sectors. Their commitment to innovation and continuous improvement has allowed them to develop a comprehensive range of heat shrinkable sleeves that are known for their durability, reliability, and superior performance.

The newly launched heat shrinkable sleeves by [Company Name] are engineered to withstand extreme conditions and provide long-lasting protection for cables, wires, and other critical components. These sleeves are designed to shrink when heat is applied, creating a tight and secure seal around the object they are protecting. This helps to effectively insulate and shield the components from moisture, corrosion, and other environmental hazards, ensuring their longevity and performance.

One of the key features of the heat shrinkable sleeves offered by [Company Name] is their ease of installation and use. These sleeves are designed to be simple and convenient to apply, making them suitable for a wide range of applications and environments. Whether it's for electrical insulation, cable bundling, or corrosion protection, these sleeves offer a cost-effective and efficient solution for various industrial needs.

In addition to their practical benefits, the heat shrinkable sleeves from [Company Name] are available in a variety of sizes, colors, and materials, allowing customers to choose the right product that best meets their specific requirements. This customization capability ensures that customers can find the perfect solution for their unique application, without compromising on quality or effectiveness.

Furthermore, [Company Name] is dedicated to providing exceptional customer service and support, ensuring that their clients receive the guidance and assistance they need to make informed decisions about their heat shrinkable sleeve requirements. The company's team of experts are readily available to provide technical advice, product recommendations, and after-sales support, further enhancing the overall customer experience.

As a company that places a strong emphasis on quality and reliability, [Company Name] ensures that their heat shrinkable sleeves undergo rigorous testing and quality control measures to meet the highest industry standards. This commitment to excellence has earned them a reputation for delivering products that consistently exceed customer expectations, setting them apart as a preferred supplier in the heat shrinkable product market.

The launch of the new line of heat shrinkable sleeves by [Company Name] is a testament to their ongoing dedication to innovation and continuous improvement. By introducing these advanced and versatile products, the company aims to address the evolving needs of their customers while maintaining their position as a market leader in the heat shrinkable product industry.

In conclusion, the introduction of the latest range of heat shrinkable sleeves by [Company Name] is set to redefine the standards of protection and insulation for various components across different industries. With their high-quality, reliable, and user-friendly products, [Company Name] continues to demonstrate their commitment to providing innovative solutions that meet the diverse needs of their customers. As the demand for advanced heat shrinkable products continues to grow, [Company Name] remains at the forefront, delivering products that consistently outperform expectations and set new benchmarks for excellence in the industry.

Company News & Blog

Discover the Innovative Self Closing Cable Sleeve for Hassle-Free Cable Management

Self Closing Cable Sleeve Revolutionizes Cable ManagementIn the age of technology and digital connectivity, the need for effective cable management has become more crucial than ever. Messy and tangled cables not only result in an unsightly workspace but can also lead to potential hazards such as tripping over wires or accidental disconnections. To address this issue, a leading company in cable management solutions has introduced a cutting-edge product: the Self Closing Cable Sleeve.Traditional cable management solutions often involve the use of zip ties, Velcro straps, or messy adhesive tapes. However, these methods are time-consuming, require constant adjustments, and may even damage the cables. The Self Closing Cable Sleeve, on the other hand, offers a quick and efficient way to manage cables while ensuring their safety and longevity.The Self Closing Cable Sleeve is made from high-quality and durable materials, designed to withstand the wear and tear of daily use. Its innovative design features a self-closing mechanism, allowing users to easily insert and remove cables as needed. Once the cables are placed inside the sleeve, the self-closing feature locks them securely in place, preventing any accidental slips or tangling.One of the key benefits of the Self Closing Cable Sleeve is its versatility. It is available in various sizes to accommodate different cable thicknesses, making it suitable for a wide range of applications. Whether used in offices, homes, entertainment centers, or even automotive settings, this cable sleeve provides a neat and organized solution to cable management.Furthermore, installation of the Self Closing Cable Sleeve is a breeze. It does not require any specialized tools or expertise. Users simply need to wrap the sleeve around the cables, and the self-closing mechanism will take care of the rest. Adjustments can easily be made by opening the sleeve and rearranging the cables, allowing for a hassle-free cable management experience.Safety is another paramount feature of the Self Closing Cable Sleeve. Its flame-retardant material ensures that in the event of a fire, the sleeve will not contribute to the spread of flames. Additionally, the sleeve minimizes the risk of electrical hazards by providing insulation to the cables and protecting them from external factors such as moisture or dust.Beyond its practical advantages, the Self Closing Cable Sleeve also improves the aesthetics of any space. With its sleek and streamlined design, it eliminates the sight of tangled cables, creating a cleaner and more professional environment. Whether in a workspace or living area, the cable sleeve enhances the overall appearance and professionalism of the area.Recognizing the needs of various industries and consumers, {} has developed the Self Closing Cable Sleeve to be an eco-friendly solution. The sleeve is manufactured using recycled materials, reducing its environmental impact. Its durability also ensures a longer lifespan, reducing the need for frequent replacements and subsequently reducing waste.By introducing the Self Closing Cable Sleeve to the market, {} has revolutionized cable management, offering a simple and effective solution to an age-old problem. With its innovative design, versatility, safety features, and environmental consciousness, the cable sleeve has quickly garnered attention and positive feedback from users across various industries.From offices aiming for a clutter-free workspace to homeowners seeking an organized entertainment center, the Self Closing Cable Sleeve is the go-to solution. Its convenience, functionality, and aesthetic appeal make it an indispensable tool for managing cables effectively while creating a visually pleasing environment. {} strives to continue innovating in the field of cable management solutions, improving the way we connect and function in our increasingly wired world.

Effective Fire Protection Sleeve Secures Your Safety

[Company Name], Pioneers of Cutting-edge Fire Protection Sleeve TechnologyIn today's fast-paced world, businesses continually strive to enhance safety measures to protect their assets and workforce. One industry that plays a vital role in safeguarding against fires is fire protection. A proud frontrunner in this field, [Company Name], has developed a revolutionary Fire Protection Sleeve that is unparalleled in its effectiveness and efficiency.Established in [year], [Company Name] has been dedicated to developing top-quality fire protection solutions. With years of experience and a commitment to research and innovation, they have constantly pushed the boundaries of fire safety technology. Their tireless efforts have resulted in the creation of the Fire Protection Sleeve, an extraordinary product that has gained recognition worldwide.So, what sets [Company Name]'s Fire Protection Sleeve apart? The answer lies in its cutting-edge design and advanced features. Made from state-of-the-art materials, the sleeve has exceptional fire-retardant properties, ensuring optimal protection against flames and extreme temperatures. This, combined with its ability to resist chemicals, oils, and abrasion, makes it an ideal solution for a wide range of industrial applications.One key aspect that distinguishes the Fire Protection Sleeve from its competitors is its ease of use. The sleeve can be easily fitted over cables, hoses, and pipes of various sizes, offering a seamless and hassle-free installation process. Furthermore, it provides flexibility, allowing for easy maintenance and repairs without the need for extensive disassembly.Designed with the end-user in mind, the Fire Protection Sleeve also prioritizes durability. It remains unaffected by exposure to harsh environmental conditions, ensuring long-lasting and reliable performance. This extended lifespan not only reduces the need for frequent replacements but also delivers cost-effectiveness to customers.In addition to its exceptional technical features, [Company Name]'s Fire Protection Sleeve stands out for its commitment to sustainability. The manufacturing process is designed to minimize waste and carbon emissions, meeting international standards for environmental responsibility. This commitment to eco-consciousness has earned the company accolades and recognition from environmental organizations around the world.But what truly sets [Company Name] apart is its unwavering dedication to customer satisfaction. Their team of experts is available to provide personalized guidance and support, assisting clients in selecting the most suitable Fire Protection Sleeve for their specific requirements. Moreover, the company's extensive network of distributors ensures that their products are readily available to customers globally, ensuring swift delivery and reliable after-sales service.The Fire Protection Sleeve has gained significant recognition for its outstanding performance. It has been rigorously tested and certified by accredited third-party laboratories, meeting and exceeding industry standards. With an impressive track record of success, the sleeve has been adopted by companies across various sectors, including oil and gas, automotive, marine, and construction.Looking towards the future, [Company Name] continues to invest in research and development to refine and expand its product range. Their unwavering commitment to innovation ensures that they stay at the forefront of fire protection technology, offering customers the most effective and advanced solutions available.As the world continues to prioritize safety, companies like [Company Name] will play an increasingly vital role in safeguarding lives and assets from the devastating consequences of fires. Their Fire Protection Sleeve exemplifies their dedication to excellence, delivering peace of mind to businesses globally.In conclusion, [Company Name] has proven itself to be a trailblazer in the field of fire protection. Through their groundbreaking Fire Protection Sleeve, they have revolutionized the industry, providing unparalleled safety and reliability. With a commitment to sustainability, customer satisfaction, and continuous improvement, [Company Name] is poised to remain a leader in fire safety technology for years to come.

Protective Sleeve for Electrical Wires: A Must-Have for Safety

Electrical Wire Protector Sleeve Enhances Safety and Protection for Various ApplicationsElectrical wire protection is an essential aspect of ensuring safety and efficiency in any electrical system. With the increasing demand for reliable and durable wire protection solutions, [Company Name] has introduced a cutting-edge Electrical Wire Protector Sleeve that is designed to provide superior protection for a wide range of applications.[Company Name] is a leading manufacturer of innovative and high-quality wire protection products and solutions. With a strong focus on research and development, the company has been at the forefront of delivering advanced wire protection technologies to meet the evolving needs of the electrical industry. The Electrical Wire Protector Sleeve is the latest addition to [Company Name]'s extensive line of wire protection products, and it is poised to set new standards in the industry.The Electrical Wire Protector Sleeve is engineered to safeguard electrical wires and cables from various environmental and mechanical hazards. Constructed from high-quality materials, the sleeve is designed to resist abrasion, heat, chemicals, and UV rays, ensuring long-lasting protection and performance in diverse operating conditions. The sleeve is also flame-retardant, which adds an extra layer of safety to electrical systems.One of the key features of the Electrical Wire Protector Sleeve is its flexibility and ease of installation. The sleeve can be easily slipped over wires and cables, providing a seamless and secure fit. This flexibility allows for easy maintenance and accessibility to the wires when needed, making it a practical solution for a wide range of applications.The Electrical Wire Protector Sleeve is suitable for use in various industries, including automotive, industrial, marine, and aerospace. Its robust design and superior protection capabilities make it an ideal choice for applications where wires are subjected to harsh environments and rugged conditions. Whether it's protecting wires in heavy machinery or ensuring the safety of electrical systems in vehicles, the Electrical Wire Protector Sleeve is a versatile solution that meets the demands of diverse applications.Furthermore, [Company Name] offers customization options for the Electrical Wire Protector Sleeve to meet specific application requirements. This includes the ability to tailor the sleeve's dimensions, colors, and other features to suit the unique needs of different projects. With this level of customization, customers can benefit from a tailored wire protection solution that fits their exact specifications and preferences.In addition to its functional benefits, the Electrical Wire Protector Sleeve is also designed with aesthetics in mind. Its sleek and professional appearance makes it a visually appealing choice for applications where the appearance of wires and cables is important. This attention to detail sets the Electrical Wire Protector Sleeve apart as a comprehensive solution that encompasses both form and function.[Company Name]'s commitment to quality and innovation is reflected in the development of the Electrical Wire Protector Sleeve. The company's dedicated team of engineers and technical experts has worked tirelessly to create a product that exceeds industry standards and delivers exceptional performance. This dedication to excellence has earned [Company Name] a reputation for being a trusted provider of wire protection solutions.In conclusion, the introduction of the Electrical Wire Protector Sleeve by [Company Name] represents a significant advancement in wire protection technology. With its advanced features, versatility, and customizable options, the sleeve is poised to meet the diverse needs of various industries and applications. As electrical systems continue to evolve and expand, the Electrical Wire Protector Sleeve stands ready to provide the safety and protection required for reliable operation.

Boost Performance and Protection with High Temperature Braided Sleeving

Title: High Temperature Braided Sleeving: A Game-Changer in Industrial Wiring SolutionsIntroduction:In today's fast-paced technological era, industrial enterprises are constantly seeking innovative solutions to tackle the challenges encountered during wiring installations. Enter High Temperature Braided Sleeving, a cutting-edge product that has revolutionized industrial wiring systems. In this article, we will explore the versatile features and benefits of this remarkable technology while delving into the company behind its development.Company Introduction and Expertise:{Name of the company}, a leading manufacturer in the field of industrial wiring solutions, has emerged as a pioneer in developing High Temperature Braided Sleeving. With decades of experience and a dedicated team of engineers, they have consistently pushed the boundaries of innovation to meet the ever-evolving demands of the industry.Their commitment to excellence has positioned them at the forefront of the market, garnering a reputation for delivering products of unmatched quality and reliability. By adopting state-of-the-art manufacturing processes and employing innovative materials, {Name of the company} has earned the trust of customers worldwide.Revolutionizing Industrial Wiring:Traditional wire insulation can often be easily damaged or compromised due to exposure to high temperatures, abrasion, chemicals, or even rodents. High Temperature Braided Sleeving has addressed these concerns with its superior protective properties, setting it apart from conventional options.1. Enhanced Protection: High Temperature Braided Sleeving provides a robust layer of protection for wires, cables, and hoses, shielding them from extreme temperatures ranging from -40°C to 1260°C. This exceptional thermal insulation ensures their longevity and prevents potential malfunctions or outages.2. Abrasion Resistance: The tightly braided structure of the sleeving offers excellent abrasion resistance. It safeguards the wires from external mechanical forces, such as friction or impact, bolstering their durability in rugged environments and heavy-duty applications.3. Chemical and Oil Resistance: High Temperature Braided Sleeving effectively resists various corrosive acids, oils, and solvents, making it an exceptional choice for industries dealing with hazardous materials. This remarkable resistance minimizes the risk of wire damage or failure, ensuring seamless operations.4. Versatility: High Temperature Braided Sleeving finds extensive application in aerospace, automotive, energy, telecommunications, and other industries where wire protection is paramount. Its flexibility allows it to accommodate various wire sizes and shapes, enabling users to cater to their specific needs with ease.5. Easy Installation: The braided construction of the sleeving allows for effortless installations, reducing labor costs and saving valuable time during wiring projects. It can conveniently expand and contract over irregular shapes, making it a user-friendly solution that significantly improves installation efficiency.Conclusion:With High Temperature Braided Sleeving leading the way in industrial wiring solutions, companies can confidently overcome the challenges posed by extreme temperatures, abrasion, and chemical exposure. The game-changing technology developed by {Name of the company} offers enhanced protection, durability, and versatility, ensuring that wire systems can operate seamlessly in even the harshest environments.As {Name of the company} continues to innovate with customer-centric solutions, they solidify their position as a go-to provider of comprehensive wiring solutions. Through their commitment to excellence and cutting-edge products like High Temperature Braided Sleeving, they empower industries to thrive in the face of demanding conditions, securing a future of efficient and reliable technological advancement.

Discover the Benefits of Expandable Cable Sleeving: An Essential Solution for Organizing and Protecting Cables

Title: Cutting-Edge Expandable Cable Sleeving Revolutionizes Cable ManagementIntroduction:In the constantly evolving world of technology, innovation plays a vital role in enhancing efficiency and productivity. One such breakthrough that promises to simplify cable management is the advanced Expandable Cable Sleeving developed by a leading company in the industry. With its exceptional qualities and versatility, this cutting-edge solution is set to revolutionize cable organization for various applications.I. Understanding the Expandable Cable SleevingThe Expandable Cable Sleeving is a highly flexible and durable material designed to encase cables, wires, and hoses. It is engineered to provide excellent protection against environmental factors such as abrasion, heat, chemical exposure, and electromagnetic interference (EMI). This technology ensures the safe and optimal performance of cables while maintaining a neat and organized appearance.II. Key Features and Benefitsa. High Expandability: The unique design of this cable sleeving enables it to expand up to four times its original diameter, making it adaptable to cables of varying sizes. This expandability facilitates easy installation and removal, eliminating the need for cutting or disassembling the cables.b. Superior Protection: The Expandable Cable Sleeving acts as a shield, safeguarding cables from potential damage caused by external impacts, including abrasion, cuts, dust, and moisture. It also provides insulation against high temperatures and protects against EMI, ensuring uninterrupted data transmission.c. Flexibility and Ease of Use: The material's exceptional flexibility allows for simple and hassle-free cable routing, even in tight spaces or complex configurations. The sleeving can effortlessly accommodate bends, twists, and turns without compromising cable integrity.d. Aesthetically Pleasing: In addition to its practical functionalities, this cable sleeving enhances the overall appearance of cable systems. It neatly groups and conceals multiple cables, creating a clean and organized look that also improves safety by reducing the risk of tripping or accidental disconnection.e. Maintenance and Durability: Made from high-quality materials, the Expandable Cable Sleeving exhibits remarkable durability, ensuring long-lasting protection for cables. Its resistance to oils, chemicals, and UV rays makes it suitable for a wide range of industrial applications, including automotive, aerospace, telecommunications, and home electronics.III. Applications and Market PotentialThe Expandable Cable Sleeving has vast applications across various sectors. In the automotive industry, it provides efficient protection for wiring harnesses, preventing damage from engine vibrations and harsh environmental conditions. In aerospace, this sleeving ensures the safe transmission of vital signals and power supply throughout complex aircraft systems. It also finds application in data centers, telecommunications networks, robotics, and audio/video installations.As the demand for cable management solutions escalates with the growing complexity of digital infrastructures, the potential market for this innovative product is substantial. With its reputation for providing cutting-edge solutions and a strong foothold in the industry, the company is poised to capture a significant share in this expanding market.IV. ConclusionThe all-new Expandable Cable Sleeving presents a groundbreaking solution that promises to revolutionize cable management. With its exceptional characteristics, including adaptability, protection, aesthetics, ease of use, and durability, this product ensures safe and efficient cable organization across various industries. As technology continues to advance, the flexibility and reliability of this cable sleeving will play a crucial role in keeping systems functioning optimally, establishing it as an indispensable tool for cable management.

New Membrane Support Technology Set to Revolutionize Industry

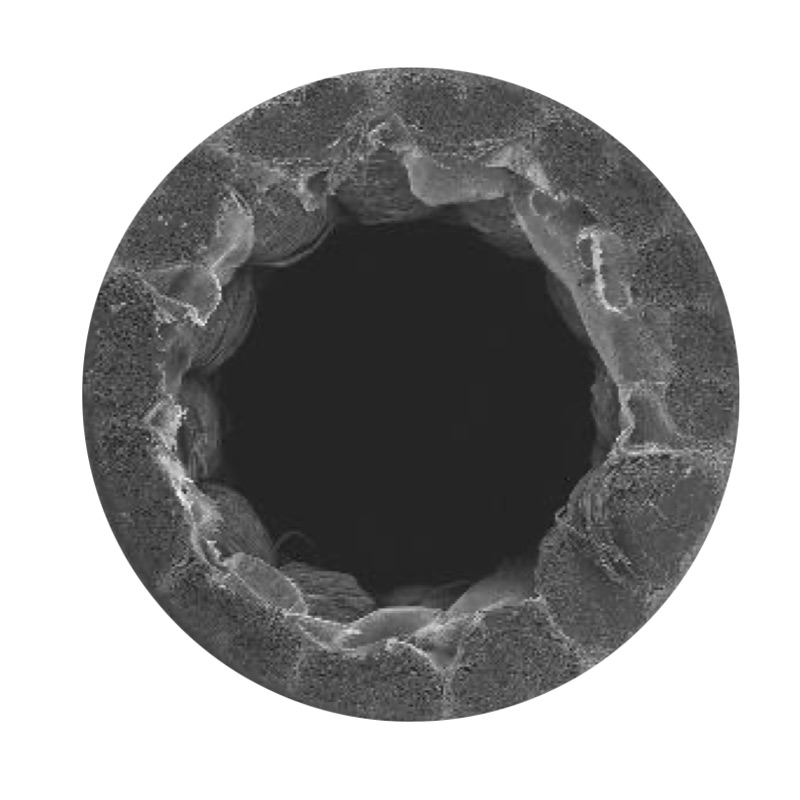

Membrane Support, a leading provider of innovative solutions for the water and wastewater treatment industry, has recently launched a new range of cutting-edge membrane support products designed to enhance the performance and efficiency of membrane filtration systems.Founded in 2005, Membrane Support has quickly established itself as a key player in the water treatment industry, known for its commitment to developing high-quality, reliable products that address the evolving needs of the market. The company's extensive expertise in membrane technology and filtration processes has enabled it to create a diverse portfolio of solutions that cater to a wide range of applications, from industrial and municipal water treatment to desalination and wastewater recycling.The latest addition to Membrane Support's product lineup includes a variety of membrane support products that have been engineered to deliver superior performance and durability. These products are specifically designed to provide optimal support for membrane filtration systems, ensuring their long-term efficiency and longevity. The advanced materials and construction techniques used in the manufacturing process result in products that are highly resistant to fouling, scaling, and other common issues that can compromise the performance of membrane systems.One of the key features of Membrane Support's new range of products is their versatility, with solutions available for a wide range of membrane configurations, including spiral-wound, hollow fiber, and tubular membranes. This flexibility enables customers to find the perfect fit for their specific requirements, whether they are operating small-scale residential systems or large-scale industrial facilities.In addition to offering superior performance, Membrane Support's products also prioritize ease of installation and maintenance, reducing downtime and overall operational costs. The company's dedication to providing comprehensive support and technical expertise ensures that customers can rely on their products to deliver consistent results, backed by responsive and knowledgeable customer service.Furthermore, Membrane Support is committed to sustainability and environmental responsibility, with its products designed to contribute to the efficient use of water resources and the reduction of energy consumption. By optimizing the performance of membrane filtration systems, Membrane Support helps its customers minimize their environmental impact while maximizing the effectiveness of their water treatment processes.The launch of the new range of membrane support products marks a significant milestone for Membrane Support, further solidifying its position as a leading provider of innovative solutions for the water treatment industry. Leveraging its extensive experience and technical capabilities, the company continues to push the boundaries of membrane technology, delivering solutions that meet the evolving needs of the market and contribute to the overall improvement of water treatment processes worldwide.With its unwavering commitment to quality, performance, and customer satisfaction, Membrane Support is poised to make a lasting impact in the water and wastewater treatment industry, setting new standards for membrane support solutions and driving advancements in the field of membrane technology. As the company continues to expand its product offerings and reach new markets, it remains dedicated to its core values of innovation, reliability, and sustainability, shaping the future of water treatment with its groundbreaking solutions.

Discover the Benefits of Polyester Braided Sleeving for Your Needs

Polyester Braided Sleeving Provides Superior Protection for Electrical WiresIn the digital age, the need for reliable and efficient electrical wiring solutions is more important than ever. Businesses and individuals rely on secure and stable power transmission to keep their operations running smoothly. This is where polyester braided sleeving comes in.Polyester braided sleeving is a tubular sleeve of woven polyester fibers that are designed to protect and cover electrical wires, hoses, and tubing. This type of covering provides a superior level of protection against abrasion, cuts, and other mechanical damage, and also offers resistance to chemicals, solvents, and UV rays.One of the leading manufacturers of polyester braided sleeving is {{Company Name}}, a company known for its high-quality electrical components. With a focus on innovation and customer satisfaction, the team at {{Company Name}} has developed a range of polyester braided sleeving products that are tailored to meet the needs of various industries.{{Company Name}}’s polyester braided sleeving is available in a range of diameters and colors, making it a versatile option for all types of wiring applications. The sleeves are also easy to install, thanks to their expandable design. They can be easily slipped over wires and cables, providing instant protection.One of the key benefits of polyester braided sleeving is its ability to reduce the risk of electrical fires. Electrical fires can occur when wires are exposed to excessive heat or become damaged due to abrasion or other factors. Polyester braided sleeving can help to prevent this by providing a protective layer that acts as a barrier against heat and other damaging elements.Another advantage of polyester braided sleeving is that it can help to extend the life of electrical wires. When wires are exposed to the elements, they can become worn and damaged over time. This can lead to costly repairs or replacements. By using polyester braided sleeving, wires are protected from the elements, making them last longer and perform better.Polyester braided sleeving from {{Company Name}} is also environmentally friendly. The sleeves are made from a high-quality, recyclable material that is free from harmful chemicals. This makes it an ideal choice for businesses and individuals who are looking for sustainable and eco-friendly solutions.Overall, polyester braided sleeving is a cost-effective and reliable solution for protecting electrical wires and cables. It offers superior protection against abrasion, cuts, and other types of damage, and is easy to install and maintain. With a range of diameters and colors to choose from, {{Company Name}}’s polyester braided sleeving is an excellent choice for businesses and individuals who are looking for quality, reliability, and superior performance.

New Innovation: Self-Closing Sleeve for Power Cables Improves Safety and Efficiency

article:Self-Closing Power Cable Sleeves: A Breakthrough in Cable Management TechnologyCable management has been an age-old problem among individuals and businesses alike. With the increasing number of devices we use on a day-to-day basis, the demand for organizing cables and wires has become more important than ever. Cables can easily tangle, tangle, or can become a potential hazard for those working in close proximity. Thankfully, there is a solution in the form of self-closing power cable sleeves.A leading manufacturer in cable management, has created a breakthrough product in the form of a self-closing power cable sleeve. This unique product has been designed to provide a simple and safe solution to tangle and clutter-prone wires and cables. The cable sleeve is made from high-quality materials that are both durable and resistant to wear and tear.The self-closing power cable sleeve features an innovative design that allows users to easily add or remove cables as needed. The sleeve is made from a flexible material that expands and contracts to accommodate different-sized cables, making it a versatile product to use.Another key feature of the self-closing power cable sleeve is its safety feature. The sleeve is designed to fully encase the cables, protecting them from potential hazards such as moisture, dust, or abrasions. The cable sleeve's self-closing design ensures that cables are kept away from sharp edges, preventing any possible damages.Installation of the self-closing power cable sleeve is a breeze. The sleeve can be easily installed by sliding it over the cables, and it will stay in place, preventing the cables from being pulled out. After installation, the sleeve can be easily removed to access the cables or add new ones.The company is committed to providing high-quality cable management solutions to its customers. They have invested a significant amount of time and funds into research and development to create innovative products that can meet the ever-changing needs of users. Their self-closing power cable sleeve is no exception, as it is designed to make cable management easier, safer, and more efficient.The self-closing power cable sleeve is ideal for use in a variety of settings. It is ideal for use in homes, offices, and workplaces, where cables need to be organized and kept away from potential hazards. The sleeve can be used on different-sized cables, making it a product that can be used across a variety of devices.Overall, the self-closing power cable sleeve is a breakthrough product that represents the future of cable management technology. The product's innovative design, safety features, ease of installation, and versatility make it a must-have for anyone who values organized cables and a clutter-free workspace. The company is proud to provide customers with a product that can make their lives simpler and safer.

Everything You Need to Know About the Versatile Carbon Fiber Braid

Carbon Fiber Braid Revolutionizes Manufacturing Processes in Various Industries[Company Name], a leader in innovative composite materials, is set to revolutionize manufacturing processes across industries with its latest product, Carbon Fiber Braid. The company's commitment to pushing the boundaries of composite materials and their applications has led to the development of a game-changing technology that promises increased strength, durability, and versatility. This breakthrough innovation has caught the attention of industry experts, who believe it will reshape manufacturing in fields as diverse as automotive, aerospace, and construction.Carbon fiber, renowned for its exceptional strength-to-weight ratio, has been widely used in industries where lightweight and durable materials are crucial. However, the conventional manufacturing methods for carbon fiber products can be labor-intensive and time-consuming. This is where [Company Name]'s Carbon Fiber Braid sets itself apart. By utilizing advanced braiding technology, the company has successfully optimized the manufacturing process, making it faster, more cost-effective, and highly scalable.The Carbon Fiber Braid consists of multiple carbon fiber tows intertwined in an intricate 3D pattern, resulting in a braided structure with remarkable mechanical properties. This unique design enhances the material's resistance to impact, fatigue, and stress, making it ideal for applications that require high performance and reliability. Furthermore, the braid configuration allows for easy customization, enabling manufacturers to tailor the product according to their specific requirements. This versatile feature makes Carbon Fiber Braid adaptable to a wide range of applications.In the automotive industry, Carbon Fiber Braid is set to revolutionize vehicle design and manufacturing. With its superior strength and lightweight characteristics, it offers significant potential for reducing vehicle weight, resulting in improved fuel efficiency and lower emissions. Additionally, its increased impact resistance enhances passenger safety without compromising performance. Automobile manufacturers can now leverage this cutting-edge technology to create lighter, safer, and more fuel-efficient vehicles.Similarly, the aerospace industry stands to benefit immensely from the introduction of Carbon Fiber Braid. By replacing traditional metal components with this innovative material, aircraft manufacturers can reduce the weight of their aircraft, resulting in reduced fuel consumption and increased payload capacity. The enhanced mechanical properties of Carbon Fiber Braid make it an ideal choice for critical components such as wing structures, landing systems, and rotor blades. This breakthrough technology promises to revolutionize the aerospace industry by enabling the production of more efficient and eco-friendly aircraft.Construction is yet another sector that can leverage the advantages of Carbon Fiber Braid. The material's unmatched strength ensures the integrity and longevity of buildings, bridges, and infrastructure projects. By incorporating Carbon Fiber Braid into construction processes, builders can significantly reduce the weight of structures while maintaining structural stability. This not only increases construction efficiency but also reduces transportation costs and environmental impact. From strengthening concrete structures to reinforcing seismic zones, Carbon Fiber Braid ushers in a new era of sustainable and resilient construction practices.[Company Name] has already collaborated with several prominent industry players to conduct extensive testing and validation of Carbon Fiber Braid. Initial results have been overwhelmingly positive, further solidifying its potential to revolutionize various manufacturing processes. The company's commitment to research and development ensures that this breakthrough technology will continue to evolve, bringing about untapped possibilities for numerous industries.In conclusion, Carbon Fiber Braid represents a game-changing innovation in the field of composite materials. By utilizing advanced braiding technology, [Company Name] has optimized the manufacturing process, resulting in a versatile and high-performance material. With its exceptional mechanical properties, Carbon Fiber Braid promises to revolutionize manufacturing processes in industries such as automotive, aerospace, and construction. The future is bright for Carbon Fiber Braid and the exciting possibilities it offers for creating more efficient, sustainable, and resilient products.

New Multilayer Braided Fabric Allows for Customizable Strength and Durability

Title: Groundbreaking Composite Braid Revolutionizes Multiple IndustriesIntroduction:The composite materials industry has recently witnessed a groundbreaking development with the emergence of a revolutionary product called the Composite Braid. This innovative solution has the potential to significantly transform various industries by offering enhanced strength, durability, and versatility. Developed by a prominent materials technology company, the Composite Braid is poised to revolutionize fields such as aerospace, automotive, and construction.(Company Name), a leader in advanced materials technology, has introduced the Composite Braid, a game-changing product that combines cutting-edge materials science with innovative manufacturing techniques. This composite braid is poised to redefine the way industries approach designing and constructing high-performance components, as it outperforms conventional materials in various aspects.1. Aerospace Industry:The aerospace sector stands to benefit immensely from the revolutionary Composite Braid. With its exceptional strength-to-weight ratio and resistance to extreme temperatures, this advanced material has the potential to push the boundaries of aviation technology. Aircraft structures reinforced with the Composite Braid will be significantly lighter and more fuel-efficient, while maintaining the necessary structural integrity to withstand high-stress conditions. By enabling manufacturers to reduce weight and maximize fuel efficiency, the Composite Braid can pave the way for more sustainable and cost-effective air travel.2. Automotive Industry:In the automotive industry, the Composite Braid offers the potential for significant improvements in vehicle safety, performance, and energy efficiency. Merging the Composite Braid with traditional manufacturing processes allows for the creation of lightweight, yet exceptionally strong vehicle components. Enhancing the structural integrity of automobiles can lead to enhanced safety during collisions, reducing the risk of injuries for passengers. Additionally, reduced weight results in improved fuel economy, lessening environmental impact and decreasing operating costs for consumers.3. Construction & Infrastructure:The Composite Braid holds great promise for the construction and infrastructure sectors. Traditional materials, such as steel and concrete, often face challenges in terms of weight, corrosion, and limited lifespan. By utilizing the Composite Braid, builders can construct structures that are not only stronger but also more durable and resistant to environmental factors. Its corrosion-resistant properties and high strength make it an ideal material for reinforcing bridges, buildings, and other critical infrastructure, ensuring their longevity and reliability.Furthermore, the versatility of the Composite Braid allows for the creation of complex and intricate architectural designs that were previously unattainable. Architects and designers now have the opportunity to push the boundaries of creativity while maintaining necessary structural integrity.4. Manufacturing & Engineering:Beyond its applications in aerospace, automotive, and construction, the Composite Braid offers numerous advantages to the wider manufacturing and engineering sectors. Its adaptability and ease of use provide opportunities for engineers and designers to create unique and customized solutions for various applications, including sporting goods, energy storage, and medical devices. The Composite Braid's superior strength and durability ensure long-lasting performance and reliability even under extreme conditions.Conclusion:The introduction of the Composite Braid marks a significant advancement in the field of composite materials, holding immense potential to revolutionize various industries. Its lightweight, high-strength properties combined with its adaptability and resistance to environmental factors make it a game-changer across aerospace, automotive, construction, and numerous other sectors. With this revolutionary technology, (Company Name) has redefined the possibilities for design, manufacturing, and innovation, driving industries toward a more sustainable and efficient future.