Boost Performance and Protection with High Temperature Braided Sleeving

By:Admin

Introduction:

In today's fast-paced technological era, industrial enterprises are constantly seeking innovative solutions to tackle the challenges encountered during wiring installations. Enter High Temperature Braided Sleeving, a cutting-edge product that has revolutionized industrial wiring systems. In this article, we will explore the versatile features and benefits of this remarkable technology while delving into the company behind its development.

Company Introduction and Expertise:

{Name of the company}, a leading manufacturer in the field of industrial wiring solutions, has emerged as a pioneer in developing High Temperature Braided Sleeving. With decades of experience and a dedicated team of engineers, they have consistently pushed the boundaries of innovation to meet the ever-evolving demands of the industry.

Their commitment to excellence has positioned them at the forefront of the market, garnering a reputation for delivering products of unmatched quality and reliability. By adopting state-of-the-art manufacturing processes and employing innovative materials, {Name of the company} has earned the trust of customers worldwide.

Revolutionizing Industrial Wiring:

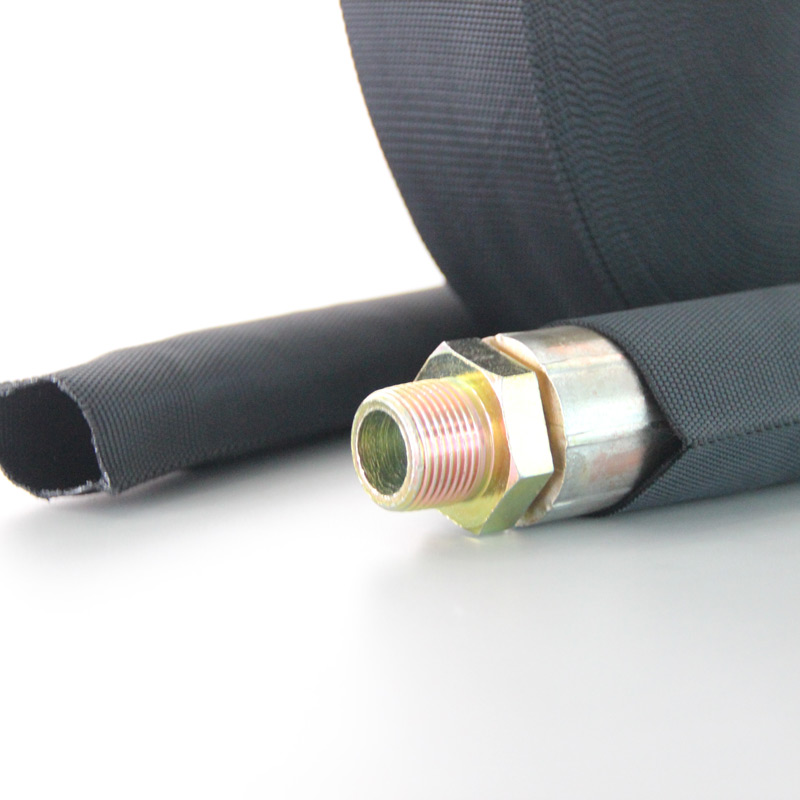

Traditional wire insulation can often be easily damaged or compromised due to exposure to high temperatures, abrasion, chemicals, or even rodents. High Temperature Braided Sleeving has addressed these concerns with its superior protective properties, setting it apart from conventional options.

1. Enhanced Protection: High Temperature Braided Sleeving provides a robust layer of protection for wires, cables, and hoses, shielding them from extreme temperatures ranging from -40°C to 1260°C. This exceptional thermal insulation ensures their longevity and prevents potential malfunctions or outages.

2. Abrasion Resistance: The tightly braided structure of the sleeving offers excellent abrasion resistance. It safeguards the wires from external mechanical forces, such as friction or impact, bolstering their durability in rugged environments and heavy-duty applications.

3. Chemical and Oil Resistance: High Temperature Braided Sleeving effectively resists various corrosive acids, oils, and solvents, making it an exceptional choice for industries dealing with hazardous materials. This remarkable resistance minimizes the risk of wire damage or failure, ensuring seamless operations.

4. Versatility: High Temperature Braided Sleeving finds extensive application in aerospace, automotive, energy, telecommunications, and other industries where wire protection is paramount. Its flexibility allows it to accommodate various wire sizes and shapes, enabling users to cater to their specific needs with ease.

5. Easy Installation: The braided construction of the sleeving allows for effortless installations, reducing labor costs and saving valuable time during wiring projects. It can conveniently expand and contract over irregular shapes, making it a user-friendly solution that significantly improves installation efficiency.

Conclusion:

With High Temperature Braided Sleeving leading the way in industrial wiring solutions, companies can confidently overcome the challenges posed by extreme temperatures, abrasion, and chemical exposure. The game-changing technology developed by {Name of the company} offers enhanced protection, durability, and versatility, ensuring that wire systems can operate seamlessly in even the harshest environments.

As {Name of the company} continues to innovate with customer-centric solutions, they solidify their position as a go-to provider of comprehensive wiring solutions. Through their commitment to excellence and cutting-edge products like High Temperature Braided Sleeving, they empower industries to thrive in the face of demanding conditions, securing a future of efficient and reliable technological advancement.

Company News & Blog

New Expandable Sleeve Designed to Increase Flexibility and Protect Cables

In today’s fast-paced world, businesses and industries are always looking for innovative ways to improve their products and services. The Expandable Sleeve is one such product, which has revolutionized the world of flexible and resilient cables. This product has been widely adopted in industries such as aerospace, automotive, medical, packaging, and robotics. The Expandable Sleeve has been manufactured by a reputed company, known for its cutting-edge technology and exceptional product quality.This innovative product has been designed to provide protection to cables, hoses, and wires against abrasion, high-temperature, chemical exposure, and other environmental factors. The sleeve is made of durable and flexible materials that allow it to expand and contract easily, making it an ideal choice for applications that require frequent and continuous movements. The Expandable Sleeve has been tested and is proven to provide excellent protection against cuts, punctures, and other damages that may occur during handling or transport.The Expandable Sleeve is versatile and can be customized to fit a wide range of applications. It is available in different sizes, materials, and colors to meet the specific needs of customers. The sleeve can be cut to a required length, and it can also be printed with logos or instructions, making it an ideal choice for branding and product identification.One of the primary advantages of the Expandable Sleeve is that it is easy to install. The sleeve can be slipped over the cables, and it can be secured in place using adhesive, cable ties, or other fastening methods. This ensures that the cable is protected, and it also improves the overall appearance of the installation.In addition to its protective functions, the Expandable Sleeve also has other benefits. It reduces the amount of waste generated during cable installation and maintenance. This is because the sleeve can be reused, reducing the need for replacement sleeves. Furthermore, the sleeve is an eco-friendly solution, as it is made of recyclable materials.The company that manufactures the Expandable Sleeve is a reputable and established organization. The company is committed to providing high-quality products and services to its customers. The company's experienced team of professionals ensures that each product is manufactured using state-of-the-art technology and meets the highest quality standards. The company's commitment to excellence is reflected in the success of the Expandable Sleeve, which has become a trusted and reliable product in various industries.In conclusion, the Expandable Sleeve is a game-changer in the world of flexible and resilient cables. It provides excellent protection against environmental factors, reduces waste, and is an eco-friendly solution. The product’s versatility and customization options make it an ideal choice for a wide range of applications. With a reputable manufacturer and a commitment to quality, the Expandable Sleeve is a reliable and innovative product that has received positive feedback from various industries.

Braided Cable Sheath: Enhancing Protection and Durability

Title: Innovative Braided Cable Sheath Enhances Durability and FunctionalityIntroduction:In today's fast-paced and interconnected world, cables have become an integral part of our lives, facilitating seamless connectivity and powering a wide range of devices. As technology evolves, there is a growing need for cables that can withstand the demands of daily use, offering enhanced durability without compromising on functionality. This is where the innovative Braided Cable Sheath, developed by an industry-leading company, comes into play. With its unique design and advanced features, this cable sheath is set to revolutionize the market.Body:1. Overview of Braided Cable Sheath:The Braided Cable Sheath, a creation of a renowned company, is engineered to provide a robust and long-lasting solution for cable protection. This innovative sheath adopts a braided design, ensuring superior flexibility and durability compared to traditional cable housing. By combining high-quality materials with cutting-edge manufacturing techniques, this cable sheath delivers exceptional performance in challenging environments.2. Unmatched Durability:One of the standout features of the Braided Cable Sheath is its remarkable durability. The blend of high-tensile strength materials and a tightly woven braided pattern creates a protective barrier that safeguards cables against abrasion, bending, and impacts. This means that users can rely on these cables even in high-stress situations, both indoors and outdoors, ensuring uninterrupted connectivity.3. Enhanced Functionality:Beyond its durability, the Braided Cable Sheath offers several features that enhance functionality and user experience. With its remarkable flexibility, the sheath allows for easy cable management, minimizing tangles and knots. Moreover, the braided design dissipates heat efficiently, preventing overheating issues often associated with prolonged use of cables. This not only improves the lifespan of the cables but also provides a safe and reliable connection for users.4. Versatility:The Braided Cable Sheath is designed to cater to a wide range of applications. Its adaptability allows it to be used in various industries, including consumer electronics, telecommunications, automotive, and aerospace. Whether it is used for charging cables, data transfer cables, or audio-video connections, this versatile sheath ensures optimal performance and longevity.5. Industry-leading Standards:The company behind the Braided Cable Sheath is well-known for its commitment to adherence to industry standards. The sheath undergoes rigorous testing to meet and exceed the highest quality requirements, ensuring that each product is reliable, safe, and long-lasting. Additionally, with a dedicated team of experts and engineers, the company implements continuous research and development efforts to stay ahead of evolving technological needs.6. Eco-conscious Manufacturing:In an era of environmental awareness, it is encouraging to note that the Braided Cable Sheath is manufactured with sustainability in mind. The company employs eco-friendly practices throughout the production process, minimizing waste generation and utilizing recyclable materials. By choosing these innovative cable sheaths, users can contribute to a greener future.Conclusion:The introduction of the Braided Cable Sheath marks a significant advancement in cable protection technology. With its unbeatable durability, enhanced functionality, versatility, and adherence to industry standards, this innovative sheath is set to become the go-to choice for various sectors. As technology continues to evolve, the Braided Cable Sheath ensures that cables keep pace with the demands of modern connectivity while offering a reliable and long-lasting solution.

Discover the Benefits of Heat Treated Fiberglass Sleeving for Various Applications

Heat Treated Fiberglass Sleeving Offers Enhanced Protection for Electrical Applications[Company Name], a leading provider of high-quality materials for various industries, is pleased to introduce its latest product – Heat Treated Fiberglass Sleeving. This innovative sleeving offers enhanced protection for electrical applications, ensuring safety and durability.Electrical applications are constantly exposed to extreme temperatures, vibrations, and mechanical stress. Without adequate protection, wires and cables can be at risk of damage, leading to potential hazards such as short circuits, fires, and equipment malfunctions. Traditional sleeving materials may not provide sufficient insulation or resistance, making them less effective in demanding environments.Recognizing the need for a reliable solution, [Company Name] has developed Heat Treated Fiberglass Sleeving. This sleeving is manufactured using a unique process that involves subjecting the fiberglass material to high temperatures, resulting in enhanced durability and resistance. The heat treatment strengthens the material, making it more capable of withstanding challenging conditions.One of the main advantages of Heat Treated Fiberglass Sleeving is its outstanding resistance to heat. With a maximum continuous operating temperature of [temperature], this sleeving can effectively protect wires and cables in environments where temperatures can reach extreme levels. This feature is particularly crucial for applications in industries such as aerospace, automotive, and telecommunications, where the risk of overheating can be a common concern.In addition to its heat resistance, Heat Treated Fiberglass Sleeving also offers excellent chemical resistance. It can withstand exposure to various chemicals, acids, and bases, ensuring that the sleeving maintains its integrity and performance even in harsh chemical environments. This feature makes it suitable for applications in industries such as oil and gas, chemical manufacturing, and industrial automation.Furthermore, Heat Treated Fiberglass Sleeving provides exceptional electrical insulation properties. It has a high dielectric strength, effectively preventing the leakage of electrical current. This insulation is crucial for applications where electrical conductivity needs to be minimized, reducing the chance of electrical accidents. Industries such as power generation, electronics, and renewable energy can greatly benefit from this feature.In terms of mechanical strength, Heat Treated Fiberglass Sleeving offers superior resistance to abrasion, cuts, and punctures. Its durable construction ensures that the sleeving remains intact, even under heavy mechanical stress. This protective property is particularly important for applications where wires and cables are frequently subjected to movements, vibrations, or harsh environmental conditions.[Company Name] is committed to delivering products that meet the highest quality standards. As a result, all Heat Treated Fiberglass Sleeving undergoes rigorous testing and strict quality control procedures to ensure its reliability and performance. With a focus on customer satisfaction, [Company Name] strives to provide solutions that exceed expectations and offer long-term value.To summarize, the introduction of Heat Treated Fiberglass Sleeving by [Company Name] brings a new level of protection and durability to electrical applications. With its exceptional heat resistance, chemical resistance, electrical insulation properties, and mechanical strength, this sleeving offers a reliable solution for a wide range of industries. [Company Name] continues to innovate and provide high-quality materials, making it a trusted partner for businesses worldwide.

Ultimate Guide to Choosing the Right Oven Gasket and Glass Seal

Title: Leading Oven Manufacturer Releases Innovative Oven Gasket and Glass Seal for Enhanced Kitchen SafetyIntroduction:[Company Name], a renowned leader in the appliance industry, has unveiled its latest groundbreaking product—an advanced oven gasket and glass seal designed to cater to the evolving needs of modern kitchens. With a rich history of producing high-quality appliances, [Company Name] continues to extend its innovative range, prioritizing safety, efficiency, and durability. This latest addition to their product lineup is set to revolutionize the way users experience their oven cooking, ensuring utmost safety and convenience.Body:1. Rising Demand for Kitchen Safety:In response to the growing emphasis on kitchen safety among consumers, [Company Name] conducted extensive research to address the need for improved oven features. Over the years, inefficient oven gaskets and glass seals have been a common concern for households, leading to potential accidents, heat loss, and compromised cooking experiences. Recognizing this, [Company Name] embarked on a mission to redefine oven safety.2. The Next Generation Oven Gasket:The new oven gasket developed by [Company Name] is an industrially advanced solution that provides reliable protection against heat leaks and prevents accidental burns during cooking. Utilizing cutting-edge technology and superior materials, this gasket offers enhanced insulation capabilities, maintaining airtight seals around the oven door. With improved heat retention, users can experience consistent and energy-efficient cooking, while also minimizing the risk of unwanted accidents.3. Revolutionary Glass Seal Technology:In addition to the oven gasket, [Company Name] has also introduced an innovative glass seal to ensure utmost safety and durability of oven doors. Built with high-grade materials that withstand extreme heat, this seal effectively prevents sudden glass breakage caused by thermal stress, offering peace of mind to homeowners. By enhancing the durability of oven glass, [Company Name] has eliminated potential hazards associated with overheating, enhancing kitchen safety and usability.4. Quality Assured:[Company Name] is committed to the highest quality standards, employing rigorous testing measures during the development process. The oven gasket and glass seal have undergone extensive testing in state-of-the-art laboratories, ensuring optimal performance and longevity. With a focus on durability, these products can withstand regular oven usage and extreme temperature fluctuations, making them a dependable choice for homeowners and professional chefs alike.5. User-Friendly Installation:Understanding the importance of ease-of-use, [Company Name] has designed the oven gasket and glass seal to be user-friendly during installation. Homeowners can effortlessly remove the old gasket and seal, replacing them with the new, improved versions. A comprehensive installation guide, along with instructional videos, is provided to assist users in correctly fitting the gasket and seal, offering a hassle-free experience.6. Enhanced Kitchen Experience:By prioritizing safety, [Company Name] aims to enhance each user's kitchen experience. These latest developments in oven gasket and glass seal technology not only provide superior safety features but also improve overall cooking performance, energy efficiency, and ease of use. Home chefs and professionals alike can now enjoy worry-free cooking with perfectly insulated ovens.Conclusion:With the release of its advanced oven gasket and glass seal, [Company Name] continues to push boundaries in the appliance industry, delivering innovative solutions to enhance kitchen safety. By addressing common concerns regarding heat leakage and glass breakage, [Company Name] reaffirms its commitment to providing high-quality products that prioritize user comfort, convenience, and peace of mind. The revolutionary oven gasket and glass seal mark yet another milestone for [Company Name], solidifying its position as a trusted and forward-thinking leader in the industry.

Explore the Benefits of Modern Motorcycle Wiring Sleeves

Motorcycle Wiring Sleeve: Streamlining the Electrical System of Two-Wheeled MachinesThe motorcycle industry is witnessing a surge in popularity as more and more people embrace the thrill and freedom of riding on two wheels. With advancements in technology and design, motorcycles have become not only a means of transportation but also a lifestyle choice. As these machines become more sophisticated, the need for efficient electrical systems becomes paramount. This is where Motorcycle Wiring Sleeve, a cutting-edge product, comes into play, promising to streamline the wiring process and improve overall performance.Developed by an innovative company, the Motorcycle Wiring Sleeve is revolutionizing the way motorcycle wiring is handled. This flexible and durable sleeve protects the electrical cables from external elements such as dust, moisture, and vibrations. By encasing the wiring system, it provides insulation against potential short circuits and minimizes the risk of electrical failures.One of the standout features of the Motorcycle Wiring Sleeve is its versatility. It can be easily adapted to fit different motorcycle models and manufacturers. This adaptability ensures a hassle-free installation process, as mechanics and enthusiasts can use a single product instead of multiple sleeves for different motorcycle makes. With the Motorcycle Wiring Sleeve, compatibility issues become a thing of the past.Furthermore, the sleeve is designed to be aesthetically pleasing, seamlessly blending with the motorcycle's overall appearance. Its sleek and minimalistic design does not compromise the bike's visual appeal, making it a popular choice among motorcycle enthusiasts who strive for both style and functionality.In addition to its protective and aesthetic benefits, the Motorcycle Wiring Sleeve also enhances the overall performance of the motorcycle. By organizing the wiring system and reducing clutter, it improves the flow of electrical current, resulting in more efficient operation of various components. This improved efficiency translates into better fuel economy, reduced maintenance costs, and increased longevity of electrical parts.Moreover, the Motorcycle Wiring Sleeve is manufactured with high-quality materials that ensure durability and longevity. It is specifically engineered to withstand harsh weather conditions, extreme temperatures, and the wear and tear associated with regular motorcycle use. By investing in this product, motorcycle owners can rest assured that their electrical systems are well-protected and will withstand the test of time.The company behind the Motorcycle Wiring Sleeve, with its commitment to innovation and customer satisfaction, has earned a reputation as a leader in the industry. With extensive research and development, their team of experts has created a product that meets the evolving needs of motorcycle enthusiasts and mechanics alike. By working closely with manufacturers and staying up-to-date with the latest industry trends, the company has managed to deliver a product that sets a new benchmark for motorcycle wiring solutions.Furthermore, the company's customer-centric approach has not gone unnoticed. They provide excellent customer support, ensuring that their patrons can make informed decisions and receive assistance throughout the installation process. The company also offers a warranty on the Motorcycle Wiring Sleeve, reinforcing their confidence in the quality and reliability of their product.As the motorcycle industry continues to thrive, innovations like the Motorcycle Wiring Sleeve play a crucial role in enhancing the riding experience. With its protective, aesthetic, and performance-enhancing features, this product is set to become an indispensable accessory for all motorcycle enthusiasts. The Motorcycle Wiring Sleeve proves that combining functionality and style can lead to remarkable advancements in motorcycle technology.In conclusion, the Motorcycle Wiring Sleeve is a breakthrough product that addresses the challenges faced by motorcycle owners and mechanics when it comes to wiring systems. With its protective properties, versatility, and performance enhancements, this sleeve is revolutionizing the way motorcycles are wired. As motorcycle enthusiasts seek safety, efficiency, and style, the Motorcycle Wiring Sleeve continues to reshape the industry and pave the way for a more streamlined and exhilarating riding experience.

How to Protect Your Cables and Hoses from High Temperatures

[News Title][News Date][City, State] - Firesleeve Company has recently announced the launch of their newest product, a revolutionary fire-resistant sleeve designed to provide optimum protection for various applications. The Firesleeve, made from high-quality materials, is set to revolutionize the fire safety industry while serving a wide range of industries, including automotive, aerospace, and industrial sectors.The Firesleeve, which has been rigorously tested and certified to meet strict safety standards, offers reliable protection against heat, flames, and thermal exposures. With its cutting-edge design, the sleeve can withstand temperatures of up to [insert temperature] while providing an insulating layer that prevents heat transfer. This unique combination of protection and insulation sets the Firesleeve apart from other solutions available in the market."The Firesleeve is a game-changer in fire safety," says [Spokesperson's Name], the company's CEO. "We have developed a product that not only meets but exceeds industry standards, providing our customers with peace of mind knowing that their assets and personnel are protected from the dangers of fire."The Firesleeve's versatility is another feature that sets it apart from its competitors. It can be easily installed on various equipment such as hydraulic hoses, electrical cables, and pneumatic lines, making it a seamless addition to any business operation. By isolating and protecting these crucial components, the Firesleeve mitigates the risk of potential failures and damage caused by fire.Moreover, the Firesleeve's durable construction ensures its longevity, making it a cost-effective solution for businesses in the long run. Its resistance to abrasion, chemicals, and UV rays - among other external factors - makes it suitable for both indoor and outdoor applications.The Firesleeve Company, renowned for its commitment to innovation, has an extensive track record of delivering high-quality fire safety solutions to various industries. With over a decade of experience in the field, the company has continuously developed cutting-edge products that have revolutionized fire protection measures.Along with the launch of the Firesleeve, the company remains focused on expanding its product line while keeping safety at the forefront. Their team of dedicated engineers and designers work tirelessly to develop new solutions that push the boundaries of fire safety, ensuring the highest level of protection for their customers.Given the rise in fire-related incidents around the world, the Firesleeve comes at a critical time when businesses are seeking robust safety measures to protect their assets, infrastructure, and most importantly, their personnel. By investing in the Firesleeve, businesses can significantly reduce the risk of fire-related accidents, preserving both lives and valuable resources.As part of their commitment to customer satisfaction, the Firesleeve Company offers comprehensive support and guidance to their clients. Their team of experts assists in identifying the specific requirements of each business, ensuring that the Firesleeve is tailored to their particular needs. With a customer-centric approach, the Firesleeve Company aims to establish long-lasting partnerships built on trust, reliability, and a shared commitment to fire safety.The Firesleeve's innovative technology combined with the Firesleeve Company's dedication to excellence positions them at the forefront of the fire safety industry. Through their continuous pursuit of advancements and customer-focused solutions, the Firesleeve Company remains at the helm of protecting businesses and lives from the devastating consequences of fire.For more information about the Firesleeve and the Firesleeve Company, please visit [company website] or contact [contact information]. [End of Article]

Highly Durable Sleeves for Abrasion Resistance: Discover their Benefits

Title: Innovative Abrasion-Resistant Sleeves Revolutionize the IndustryIntroduction:In today's rapidly evolving industrial landscape, the need for reliable and durable solutions has never been greater. One company, renowned for its commitment to excellence and innovation, has developed a groundbreaking solution to address the frequent problem of abrasion damage in various sectors. Introducing Abrasion Resistant Sleeves, the latest revolutionary product that promises to revolutionize how industries handle wear and tear. In this article, we delve into the unique features and applications of these sleeves, exploring how they can enhance productivity and prolong the lifespan of critical components.Product Overview:Abrasion Resistant Sleeves are cutting-edge protective sheaths designed to withstand extreme environmental conditions and mechanical stress. Constructed from top-grade materials, their primary function is to shield vulnerable components from abrasion, impact, chemicals, and heat. This innovative solution offers long-lasting protection against wear and tear, significantly minimizing equipment downtime, maintenance costs, and potential safety hazards.Key Features:1. Advanced Material Composition: The sleeves employ a combination of high-performance fibers, such as aramid, UHMWPE, nylon, and polyester, ensuring excellent resistance against abrasion and other hazards commonly encountered in industrial processes.2. Exceptional Flexibility: Despite their formidable strength, the sleeves offer remarkable flexibility, allowing them to be easily slipped onto and removed from components without compromising their integrity. This feature streamlines installation and maintenance processes, saving both time and effort.3. Enhanced Heat Resistance: By incorporating flame-retardant properties, the sleeves provide additional protection against high temperatures, sparks, and welding splatters. Heat-related damage is minimized, reducing machine downtime and promoting worker safety.4. Customizable Design: The versatility of Abrasion Resistant Sleeves enables them to be tailored to specific application requirements. Custom sizing, colors, and branding options are available, allowing clients to optimize their branding efforts while maximizing product durability.Applications:1. Manufacturing and Automotive Industries: The sleeves find extensive use in automobile manufacturing, where critical components, such as hydraulic hoses, cables, and wires, are usually exposed to rigorous mechanical operation. By wrapping these components with abrasion-resistant sleeves, companies can ensure longevity and reliability, thereby improving overall productivity.2. Oil and Gas Sector: In the oil and gas industry, where harsh environments and demanding conditions prevail, Abrasion Resistant Sleeves come to the rescue. They effectively safeguard drilling equipment, pipelines, and hoses against abrasive particles, chemicals, and extreme temperatures, mitigating both long-term maintenance costs and safety risks.3. Mining and Construction: In these industries, heavy machinery and equipment are subject to constant wear and tear. The sleeves provide a robust protective layer, shielding hydraulic lines, ventilation systems, and electrical cables from abrasion, impact, and adverse weather conditions. By implementing these sleeves, companies can extend the lifespan of their machinery and optimize their operational efficiency.Conclusion:When it comes to safeguarding critical industrial components, Abrasion Resistant Sleeves stand as an exceptional solution, redefining the standards of durability and performance. Their revolutionary design and range of applications make them indispensable assets across various industries, optimizing productivity, reducing maintenance costs, and ensuring a safe working environment. As this groundbreaking solution continues to gain recognition, it is clear that Abrasion Resistant Sleeves will play an instrumental role in driving the future of industrial protection.

Keep Your Hands Safe with Cut Resistant Sleeves: A Complete Guide

Cut-resistant sleeves are a crucial safety accessory for industries that involve handling sharp objects and equipment. These sleeves provide an additional layer of protection to workers, significantly reducing the risk of injuries and accidents. One prominent brand in the market that offers high-quality cut-resistant sleeves is (brand name), known for its innovative and reliable safety products.Employee safety is of utmost importance for any company, and (brand name) understands the importance of providing top-notch protective gear. With years of experience in the industry, the company has established itself as a leader in manufacturing and supplying safety equipment. Their cut-resistant sleeves are designed using state-of-the-art materials and technology to ensure maximum protection without compromising comfort.The cut-resistant sleeves offered by (brand name) are made from high-performance fibers such as Kevlar and Dyneema. These materials are extremely strong and resistant to cuts, slashes, and abrasions. By incorporating these fibers into the sleeves, (brand name) ensures that they meet the strictest safety standards and offer reliable protection to workers in various industries.The sleeves are ergonomically designed to fit comfortably on the arms, providing freedom of movement without hindering productivity. They are available in various sizes to accommodate different arm lengths and diameters. Additionally, the sleeves are knitted with precision, ensuring a snug fit that stays in place during the most demanding and rigorous tasks.One of the noteworthy features of (brand name)'s cut-resistant sleeves is their breathability. The sleeves allow air circulation to prevent excessive sweating, keeping the wearer cool and comfortable even during prolonged use. This particular feature is crucial for industries where workers are exposed to high temperatures or work in confined spaces.Moreover, the sleeves are machine washable, making them easy to maintain and reuse. This not only saves costs but also ensures that workers have access to clean and hygienic protective gear at all times. The durability of these sleeves is also noteworthy, as they have been engineered to withstand repeated use and maintain their cut-resistant properties over time.Furthermore, (brand name) takes pride in its commitment to quality and safety. The company adheres to strict quality control measures throughout the manufacturing process to ensure that their products meet or exceed industry standards. They regularly test their cut-resistant sleeves to certify their effectiveness and reliability, providing peace of mind to both the company and its employees.To meet the diverse needs of their customers, (brand name) offers a range of cut-resistant sleeves with different levels of protection. This ensures that workers in various industries, such as construction, manufacturing, and automotive, can find sleeves that best suit their specific requirements. Whether it's protection against low-level cuts or high-level industrial hazards, (brand name) has the right sleeves for the job.In conclusion, (brand name) is a trusted provider of cut-resistant sleeves that prioritize worker safety. Their sleeves incorporate advanced materials and design features to offer reliable protection without compromising comfort. With a commitment to quality and adherence to industry standards, (brand name) continues to be at the forefront of manufacturing safety equipment that meets the needs of various industries. By investing in their cut-resistant sleeves, companies can ensure a safer working environment and protect their employees from potential injuries caused by sharp objects and equipment.

New Multilayer Braided Fabric Allows for Customizable Strength and Durability

Title: Groundbreaking Composite Braid Revolutionizes Multiple IndustriesIntroduction:The composite materials industry has recently witnessed a groundbreaking development with the emergence of a revolutionary product called the Composite Braid. This innovative solution has the potential to significantly transform various industries by offering enhanced strength, durability, and versatility. Developed by a prominent materials technology company, the Composite Braid is poised to revolutionize fields such as aerospace, automotive, and construction.(Company Name), a leader in advanced materials technology, has introduced the Composite Braid, a game-changing product that combines cutting-edge materials science with innovative manufacturing techniques. This composite braid is poised to redefine the way industries approach designing and constructing high-performance components, as it outperforms conventional materials in various aspects.1. Aerospace Industry:The aerospace sector stands to benefit immensely from the revolutionary Composite Braid. With its exceptional strength-to-weight ratio and resistance to extreme temperatures, this advanced material has the potential to push the boundaries of aviation technology. Aircraft structures reinforced with the Composite Braid will be significantly lighter and more fuel-efficient, while maintaining the necessary structural integrity to withstand high-stress conditions. By enabling manufacturers to reduce weight and maximize fuel efficiency, the Composite Braid can pave the way for more sustainable and cost-effective air travel.2. Automotive Industry:In the automotive industry, the Composite Braid offers the potential for significant improvements in vehicle safety, performance, and energy efficiency. Merging the Composite Braid with traditional manufacturing processes allows for the creation of lightweight, yet exceptionally strong vehicle components. Enhancing the structural integrity of automobiles can lead to enhanced safety during collisions, reducing the risk of injuries for passengers. Additionally, reduced weight results in improved fuel economy, lessening environmental impact and decreasing operating costs for consumers.3. Construction & Infrastructure:The Composite Braid holds great promise for the construction and infrastructure sectors. Traditional materials, such as steel and concrete, often face challenges in terms of weight, corrosion, and limited lifespan. By utilizing the Composite Braid, builders can construct structures that are not only stronger but also more durable and resistant to environmental factors. Its corrosion-resistant properties and high strength make it an ideal material for reinforcing bridges, buildings, and other critical infrastructure, ensuring their longevity and reliability.Furthermore, the versatility of the Composite Braid allows for the creation of complex and intricate architectural designs that were previously unattainable. Architects and designers now have the opportunity to push the boundaries of creativity while maintaining necessary structural integrity.4. Manufacturing & Engineering:Beyond its applications in aerospace, automotive, and construction, the Composite Braid offers numerous advantages to the wider manufacturing and engineering sectors. Its adaptability and ease of use provide opportunities for engineers and designers to create unique and customized solutions for various applications, including sporting goods, energy storage, and medical devices. The Composite Braid's superior strength and durability ensure long-lasting performance and reliability even under extreme conditions.Conclusion:The introduction of the Composite Braid marks a significant advancement in the field of composite materials, holding immense potential to revolutionize various industries. Its lightweight, high-strength properties combined with its adaptability and resistance to environmental factors make it a game-changer across aerospace, automotive, construction, and numerous other sectors. With this revolutionary technology, (Company Name) has redefined the possibilities for design, manufacturing, and innovation, driving industries toward a more sustainable and efficient future.

Protect Your Hoses with Heat Resistant Sleeves

Heat Resistant Sleeve for Hose: A Solution to Protect Your MachineryMachinery and equipment are an essential part of modern life, and they require constant upkeep to function efficiently. When it comes to high-temperature applications like industrial pipes, hoses, and wires, they need to be protected from heat damage. The good news is that there is a solution for this - a heat resistant sleeve for hoses.{Company Name}, a leading manufacturer of high-quality thermal insulation products, has recently added a heat resistant sleeve for hoses to its product portfolio. The sleeve is designed to protect hoses, wires, and cables from temperatures up to 500°F (260°C), making it ideal for use in industries such as oil and gas, chemicals, and manufacturing.The heat resistant sleeve is made of high-quality materials that resist chemical degradation, ozone, and UV radiation. It is also abrasion-resistant and provides excellent insulation, reducing energy costs and increasing the lifespan of hoses and cables.{Company Name} ‘s heat resistant sleeve is highly flexible and easy to install, making it an ideal choice for retrofitting existing systems. The sleeve can be easily slipped over the hose or cable and secured with heat shrink tape, making it fast and reliable to install.One of the most significant advantages of using {Company Name}’s heat resistant sleeve is that it significantly reduces the risk of hose failure due to heat damage. Often, high-temperature applications result in hoses and cables getting brittle, cracked, or even melted. Such damage can cause leaks, system failures, and pose serious risks to workers and equipment. By using heat resistant sleeves, companies can protect their machinery and prevent such hazardous conditions from occurring.Heat resistant sleeve for hoses is an excellent investment for companies that value safety and efficiency. The sleeve not only offers protection against high temperatures but also extends the lifespan of hoses and cables, resulting in significant savings in replacement and maintenance costs.{Company Name}’s heat resistant sleeve for hoses is a product that meets the highest standards of safety and efficiency. It is designed to help companies reduce their carbon footprint and promote sustainable practices. As a premium insulation solutions provider, the company is committed to innovation, quality, and customer satisfaction.{Company Name} is a global leader in providing thermal insulation products that meet the requirements of diverse industries. The company offers a broad range of products, including heat resistant tapes, jackets, blankets, and sleeves. Their extensive product portfolio, along with their technical expertise, allows them to provide custom solutions tailored to each client’s unique requirements.In conclusion, the heat resistant sleeve for hoses offered by {Company Name} is a highly beneficial investment for companies that value safety, efficiency, and sustainability. The sleeve protects machinery and extends the lifespan of hoses and cables, which saves costs on replacements and maintenance. As a leading global provider of insulation solutions, {Company Name} is committed to providing innovative, high-quality, and reliable products that meet and exceed industry standards.