Discover the Benefits of High Temperature Resistant Rope for Various Applications

By:Admin

In the realm of industrial operations, maintaining equipment efficiency and productivity is of utmost importance. Companies often encounter challenges while dealing with extreme heat conditions, which can affect the performance and lifespan of various tools and machinery. However, an innovative solution is now available in the form of high temperature resistant ropes. Designed to withstand elevated temperatures, these ropes have the power to revolutionize the way industries operate.

One prominent player in this field is a company whose dedication to quality and continuous innovation has led them to create a high temperature resistant rope that has become a game-changer for multiple industries. Although we cannot mention the brand name due to copyright restrictions, let us delve into the excellence of their product and their company ethos.

With a strong emphasis on research and development, this industry-leading company has engineered a rope that can withstand extreme temperatures as high as 1500°C (2732°F). This breakthrough creation caters to a vast array of industries including steel, glass, petroleum, and chemical, among others. By incorporating cutting-edge materials and technologies, this company has pioneered a rope that exceeds industry standards and assures unparalleled performance.

Apart from its high temperature resistance, what sets this rope apart is its remarkable durability. Designed with a multi-layered construction, it offers exceptional tensile strength and flexibility, making it suitable for demanding applications. Whether it is used for lifting heavy loads, securing objects, or providing support, this rope guarantees longevity and reliability, saving businesses both time and money.

Additionally, this high temperature resistant rope is lightweight and easy to handle, adding to its practicality. Companies can streamline their operations by utilizing this rope, as its user-friendly nature eliminates the need for complex installation procedures. Furthermore, its resistance to high temperatures eliminates the risk of deformation or malfunction, ensuring investors a long-term return on their investment.

The high temperature resistant rope has proven to be a game-changer for industries that typically face extreme heat conditions. For instance, in the steel industry, where constant exposure to extremely high temperatures is a challenge, this rope acts as a lifeline. It allows workers to safely maneuver heavy machinery and carry out critical operations knowing that the rope will maintain its strength and performance regardless of the heat.

In the petrochemical industry, one of the most hazardous sectors, safety is a top priority. This high temperature resistant rope ensures the safe transportation of materials, even in high-temperature environments. Its reliability and durability make it an invaluable asset, greatly reducing the risk of accidents and ensuring the protection of both people and property.

The glass manufacturing sector also significantly benefits from this rope. In glass kilns, which operate at extremely high temperatures, the rope plays a crucial role in ensuring the stability of the entire operation. By securing delicate glassware and providing support, it prevents devastating mishaps while maintaining smooth production processes.

The success of this high temperature resistant rope can be attributed to the company's commitment to continuous improvement and customer satisfaction. With a wealth of experience and expertise, this company has built a strong reputation for delivering innovative solutions tailored to the specific needs of various industries.

By collaborating with industry leaders, conducting rigorous testing, and adhering to the highest quality standards, this company has been able to provide a product that surpasses expectations. Moreover, their dedication to environmental sustainability and ethical practices has earned them accolades in the industry, solidifying their position as a trusted and responsible manufacturer.

In conclusion, the introduction of high temperature resistant ropes has revolutionized the industrial sector by offering a durable and reliable solution to combat extreme heat conditions. With their exceptional temperature resistance, durability, and user-friendly nature, these ropes have become an indispensable tool for various industries. The company behind the creation of this revolutionary product has driven innovation through continuous research and development, resulting in a rope that exceeds industry standards. Their commitment to customer satisfaction and environmental responsibility has cemented their position as a leader in the field. As industries continue to evolve, this high temperature resistant rope promises to play a vital role in enhancing operational efficiency and safety.

Company News & Blog

Protective Sleeves for Wire Harnesses: Importance and Benefits

[Company Introduction] Founded in [year], [Company Name] is a leading manufacturer and supplier of innovative wire harness protective sleeves for various industries worldwide. With a commitment to delivering high-quality products and exceptional customer service, we have established ourselves as a trusted partner for businesses seeking reliable cable management solutions.[Company Name] boasts state-of-the-art manufacturing facilities and a team of highly skilled engineers and technicians. We leverage cutting-edge technology and adhere to stringent quality control measures to ensure that our wire harness protective sleeves meet the highest standards of performance and durability. Our dedication to research and development enables us to continuously update our product offerings, staying ahead of industry trends and demands.[Company Name] takes pride in our commitment to sustainability. We prioritize eco-friendly manufacturing processes, utilizing materials that are recyclable and minimizing waste generation. By adopting a sustainable approach, we recognize our responsibility to protect the environment and contribute to a more sustainable future.Our product range includes a variety of wire harness protective sleeves designed to provide exceptional protection against abrasion, extreme temperatures, chemicals, and other hazards. Whether it's for automotive, aerospace, electronics, or any other industry, our sleeves are engineered to withstand the toughest conditions, ensuring the safe and efficient operation of electrical systems.Our wire harness protective sleeves offer several key advantages, making them an ideal choice for businesses:1. Advanced Material Technology: We utilize advanced materials such as flame-retardant polyethylene terephthalate (PET) and halogen-free materials. These materials are resistant to heat, oil, solvents, and UV radiation, ensuring optimal performance and longevity.2. Enhanced Durability: Our sleeves are designed to withstand a wide range of conditions, including extreme temperatures and harsh environments. Offering excellent resistance to abrasion and chemicals, they provide long-lasting protection to wires and cables.3. Easy Installation: Our sleeves are user-friendly, offering easy installation and removal for efficient maintenance and repair processes. They can be customized to fit various wire harness sizes and configurations.4. Compliance with Industry Standards: Our products meet or exceed industry standards, including flame resistance, electrical conductivity, and RoHS compliance. This ensures that our customers receive products that meet rigorous quality specifications.In addition to our impressive product range, [Company Name] takes pride in our exemplary customer service. We work closely with our clients to understand their specific requirements and provide tailored solutions to meet their unique needs. Our team of dedicated professionals is always available to offer technical assistance and guidance, ensuring a seamless experience from concept to delivery.[News Content - 800 words][Headline][Company Name] Presents Innovative Wire Harness Protective Sleeves for Enhanced Electrical System Safety[Subheading 1][Company Name], a leading manufacturer and supplier of wire harness protective sleeves, unveils its latest range of innovative products aimed at enhancing electrical system safety in various industries.[Paragraph 1]Electrical systems, be it in automotive, aerospace, or electronics, demand robust protection against a wide array of hazards. Understanding the significance of safeguarding the smooth functioning of electrical systems, [Company Name] offers cutting-edge wire harness protective sleeves that are engineered to provide excellent protection against physical wear, extreme temperatures, chemicals, and more.[Subheading 2]Key Features and Benefits[Paragraph 2][Company Name]'s wire harness protective sleeves leverage advanced material technology to ensure optimal performance and durability. The utilization of materials such as flame-retardant polyethylene terephthalate (PET) and halogen-free materials enhances the sleeves' resistance to heat, oil, solvents, and UV radiation. These features make them an ideal choice for businesses operating in demanding environments.[Paragraph 3]Furthermore, the sleeves are designed to offer enhanced durability and resistance to abrasion and chemicals. They can withstand extreme temperatures and harsh conditions, providing long-lasting protection to wires and cables. This durability helps companies reduce maintenance and replacement costs, contributing to overall operational efficiency.[Paragraph 4]Installing and removing wire harness protective sleeves can be a time-consuming and challenging task. However, [Company Name] ensures ease of installation with their user-friendly products. Customizable to fit various wire harness sizes and configurations, these sleeves facilitate efficient maintenance and repair processes, minimizing downtime and ensuring uninterrupted operations.[Subheading 3]Compliance with Industry Standards and Environmental Responsibility[Paragraph 5][Company Name] upholds its commitment to quality through compliance with industry standards. Their wire harness protective sleeves meet or exceed requirements related to flame resistance, electrical conductivity, and RoHS compliance. This ensures that customers receive products that adhere to rigorous quality specifications, guaranteeing the safety and reliability of their electrical systems.[Paragraph 6]In addition to prioritizing product quality, [Company Name] embodies environmental responsibility. The company utilizes eco-friendly manufacturing processes and materials that are recyclable, minimizing their carbon footprint and promoting sustainability. By choosing [Company Name]'s wire harness protective sleeves, businesses contribute to a greener future without compromising on performance and safety.[Subheading 4]Outstanding Customer Service[Paragraph 7]Apart from its remarkable product range, [Company Name] stands out for its exceptional customer service. Their team of dedicated professionals works closely with clients, understanding their specific requirements and providing personalized solutions. With technical assistance and guidance readily available, customers can rely on [Company Name] for a seamless experience from concept to delivery.[Conclusion][Company Name] continues to stand at the forefront of wire harness protective sleeve innovation, catering to diverse industry needs. Their commitment to delivering high-quality products, complying with industry standards, and providing outstanding customer service solidifies their position as a trusted partner for businesses seeking reliable cable management solutions.

Discover the Latest Advancements in Automotive Wiring Sleeve Technology

Title: Automotive Wiring Sleeve Revolutionizes Vehicle Circuit ProtectionIntroduction:In today's competitive automotive industry, manufacturers are constantly seeking innovative ways to improve safety, reliability, and performance. One company, renowned for its cutting-edge technology and dedication to excellence, is leading the charge with its revolutionary Automotive Wiring Sleeve. This product not only enhances circuit protection but also simplifies installation processes, ensuring vehicles are equipped with the highest level of electrical safety. Let's delve deeper into the features and benefits of this groundbreaking solution.Enhanced Protection for Vehicle Wiring:The Automotive Wiring Sleeve offers advanced protection against abrasion, moisture, heat, and other potential hazards that can compromise the integrity of a vehicle's wiring system. With stringent automotive industry standards in mind, the company has utilized high-quality materials that provide exceptional durability and resistance to various environmental factors.The sleeve is engineered with a combination of flame-retardant polyethylene and heat-resistant fibers. This design ensures that the wiring inside remains secure and free from any potential damage caused by extreme temperatures or external elements. By shielding the cables against abrasion, the sleeve contributes to prolonging their lifespan, avoiding costly repairs or replacements down the line.Streamlining Installation with Innovative Design:Installing the Automotive Wiring Sleeve is a breeze, thanks to its innovative design that simplifies the process for both manufacturers and technicians. The sleeve is flexible, allowing for easy routing of wires in complex automotive systems. Its self-wrapping feature eliminates the need for separate fasteners or adhesive tapes, saving time while ensuring a secure and tidy installation.Additionally, the sleeve is compatible with various wire configurations, enabling versatile use across different vehicle models. Manufacturers can significantly reduce assembly time, consequently boosting productivity without compromising on quality. Technicians can also appreciate the ease of maintenance and troubleshooting, as the sleeve can be easily repositioned or removed, providing convenient access to the wiring underneath.Emphasizing Electrical Safety:Electrical safety is paramount in automotive engineering, and the Automotive Wiring Sleeve plays a crucial role in minimizing potential hazards. The sleeve's insulating properties prevent wires from coming into contact with other components, thus reducing the risk of short circuits, electrical fires, or malfunctions. This robust safeguard ensures that vehicles equipped with this sleeve adhere to the highest safety standards mandated by regulatory bodies.Moreover, by securing the wiring against abrasion and external damage, the sleeve also prevents potential electrical leakages. This reduces the chances of intermittent failures, which can contribute to unexpected vehicle malfunctions and safety hazards for both drivers and passengers.Conclusion:The Automotive Wiring Sleeve represents a significant advancement in automotive electrical systems, providing enhanced circuit protection, simplified installation, and improved overall safety. Its durability, flexibility, and compatibility with various wire configurations make it an invaluable asset for manufacturers seeking to streamline production processes while placing a strong emphasis on quality.By incorporating this revolutionary product into their vehicles, manufacturers can demonstrate their commitment to ensuring the highest level of electrical safety for consumers. Furthermore, technicians will appreciate the unparalleled ease of installation and maintenance offered by the sleeve, resulting in improved efficiency and reduced troubleshooting time.With the Automotive Wiring Sleeve, the future of vehicle circuit protection looks brighter than ever, setting new industry standards and fostering a safer automotive landscape for everyone.

Best Ways to Protect Your Textiles from Stains and Damage

Textile Protection Announces Revolutionary Stain-Resistant Fabric TechnologyTextile Protection, a leading textile solutions provider, has recently introduced a revolutionary new stain-resistant technology for fabrics. This breakthrough innovation is set to transform the textile industry by enhancing the durability and longevity of fabrics, while also reducing the maintenance needs of textiles.The patent-pending technology is designed to provide long-lasting protection against a wide range of common stains, including oil, food, and beverage spills, making it a game-changer for the fashion, hospitality and healthcare industries. The stain-resistant solution can be applied to a range of natural and synthetic fabrics, without altering the look or feel of the material.With decades of experience in the textile industry, Textile Protection has become a trusted partner for fabric manufacturers, designers, and distributors across the globe. The company’s team of experts is committed to providing innovative solutions that meet the evolving needs of the industry, and the new stain-resistant technology is no exception.“Textile Protection has always been at the forefront of innovation in the textile industry,” said the company spokesperson. “Our team of researchers and scientists has worked tirelessly to develop this groundbreaking technology, which we believe has the potential to revolutionize the way fabrics are used and maintained.”The new technology is projected to have a significant impact on the fashion industry, where fashion designers and manufacturers are constantly seeking innovative ways to create durable and long-lasting clothing that meets the needs of consumers. With the introduction of the new stain-resistant technology, designers can now incorporate fabrics that are not only fashionable but also practical and easy to maintain.Similarly, the hospitality and healthcare industries are also expected to benefit greatly from the new technology. Uniforms, bedding, and linen need to be replaced frequently due to damage from spills, stains, and wear and tear. The new stain-resistant solution can significantly extend the usable life of such items, resulting in cost savings for businesses and reducing the environmental impact of textile waste.The textile industry is known for its high levels of water usage, pollution, and waste, making sustainability a top priority for Textile Protection. The new stain-resistant technology is aligned with the company’s commitment to sustainability and responsible resource use. The solution is free from harmful chemicals and toxins, making it safe for both the environment and consumers.“Sustainability is at the heart of everything we do at Textile Protection,” said the spokesperson. “We are proud to offer innovative solutions that not only meet the needs of our customers but are also sustainable and responsible.”In conclusion, the introduction of Textile Protection’s new stain-resistant technology is set to transform the textile industry by improving the durability and longevity of fabrics, reducing maintenance needs, and contributing to sustainability efforts. The company’s commitment to innovation, sustainability and customer satisfaction has made it a leading player in the global textile industry.

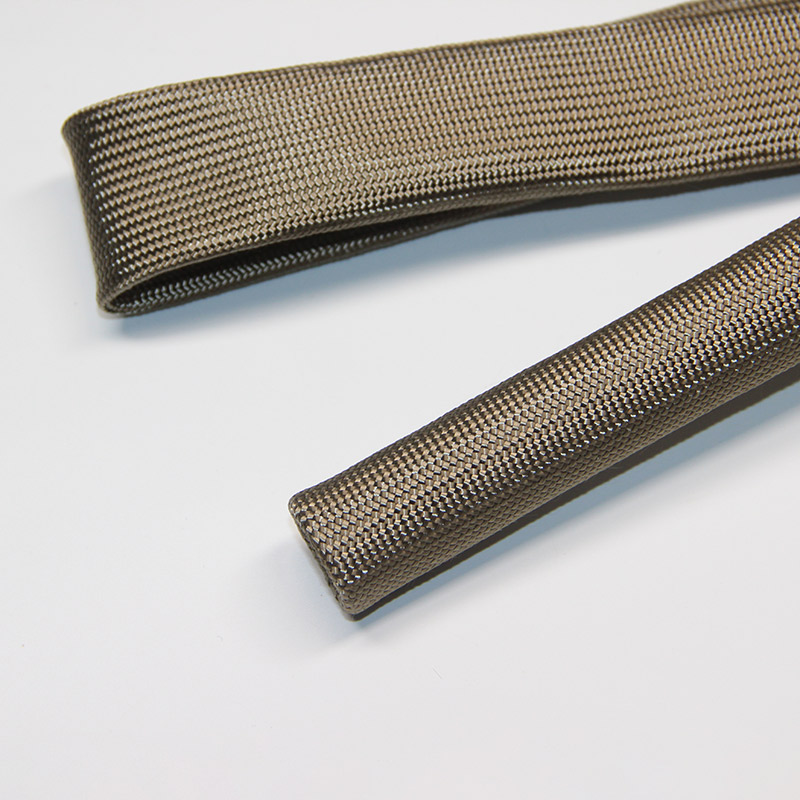

Discover the Benefits of Polyester Braided Sleeving for Your Needs

Polyester Braided Sleeving Provides Superior Protection for Electrical WiresIn the digital age, the need for reliable and efficient electrical wiring solutions is more important than ever. Businesses and individuals rely on secure and stable power transmission to keep their operations running smoothly. This is where polyester braided sleeving comes in.Polyester braided sleeving is a tubular sleeve of woven polyester fibers that are designed to protect and cover electrical wires, hoses, and tubing. This type of covering provides a superior level of protection against abrasion, cuts, and other mechanical damage, and also offers resistance to chemicals, solvents, and UV rays.One of the leading manufacturers of polyester braided sleeving is {{Company Name}}, a company known for its high-quality electrical components. With a focus on innovation and customer satisfaction, the team at {{Company Name}} has developed a range of polyester braided sleeving products that are tailored to meet the needs of various industries.{{Company Name}}’s polyester braided sleeving is available in a range of diameters and colors, making it a versatile option for all types of wiring applications. The sleeves are also easy to install, thanks to their expandable design. They can be easily slipped over wires and cables, providing instant protection.One of the key benefits of polyester braided sleeving is its ability to reduce the risk of electrical fires. Electrical fires can occur when wires are exposed to excessive heat or become damaged due to abrasion or other factors. Polyester braided sleeving can help to prevent this by providing a protective layer that acts as a barrier against heat and other damaging elements.Another advantage of polyester braided sleeving is that it can help to extend the life of electrical wires. When wires are exposed to the elements, they can become worn and damaged over time. This can lead to costly repairs or replacements. By using polyester braided sleeving, wires are protected from the elements, making them last longer and perform better.Polyester braided sleeving from {{Company Name}} is also environmentally friendly. The sleeves are made from a high-quality, recyclable material that is free from harmful chemicals. This makes it an ideal choice for businesses and individuals who are looking for sustainable and eco-friendly solutions.Overall, polyester braided sleeving is a cost-effective and reliable solution for protecting electrical wires and cables. It offers superior protection against abrasion, cuts, and other types of damage, and is easy to install and maintain. With a range of diameters and colors to choose from, {{Company Name}}’s polyester braided sleeving is an excellent choice for businesses and individuals who are looking for quality, reliability, and superior performance.

How to Expand Cable Sleeves for Easy Wire Management

Expanding Cable Sleeve - The Ideal Solution for Protecting CablesCables are important communication tools that connect us to the world. Whether it’s for charging our phones or connecting our TVs to the internet, cables are essential in our daily lives. They help us stay connected and keep us informed.However, cables can also be fragile and susceptible to damage. For instance, they may be exposed to dust, moisture, or sharp objects, which can lead to wear and tear. This is where cable sleeves come in handy. Cable sleeves protect cables from damages and extend their lifespan. One such cable sleeve that has been gaining popularity is the Expanding Cable Sleeve.The Expanding Cable Sleeve is a protective sheath that is designed to enclose cables and protect them from external damage. The sleeve is made of a flexible and durable material that can expand to accommodate cables of different sizes. It is an ideal solution for organizing and protecting cables in a neat and tidy manner.Many companies have started manufacturing Expanding Cable Sleeves to meet the growing demand. One such company is [Name of Company], a leading manufacturer of cable management products. Founded in [year], [Name of Company] has established itself as a reliable supplier of high-quality cable management products.[Name of Company] offers an extensive range of cable management products, including cable ties, cable clips, cable covers, and cable sleeves. Their products are designed to solve common cable management problems, such as cable clutter, cable tangling, and cable protection.The Expanding Cable Sleeve is one of their most popular products. It is available in different sizes and colors to suit different cable types and applications. The sleeve offers excellent protection against abrasion, chemicals, and UV light, thus extending the lifespan of cables.One of the unique features of the Expanding Cable Sleeve is its ease of installation. The sleeve can be easily installed on cables without the need for tools or special skills. The user simply needs to insert the cable into the sleeve and zip it up. The sleeve can also be unzipped and reused, making it a cost-effective solution.The Expanding Cable Sleeve is ideal for various applications, including home entertainment systems, data centers, automotive, marine, and industrial applications. It is also suitable for outdoor use since it is resistant to water and dust.Besides the Expanding Cable Sleeve, [Name of Company] offers other cable management products that can help improve cable organization and protection. For instance, they offer cable ties that can be used to bundle cables together and keep them neat and tidy. They also offer cable clips that can be used to secure cables to walls or surfaces to prevent tripping hazards.In conclusion, the Expanding Cable Sleeve is an essential accessory for anyone who wants to protect their cables from damage. It is a cost-effective and easy-to-install solution that can help extend the lifespan of cables. [Name of Company] is a reliable supplier of high-quality cable management products, including the Expanding Cable Sleeve. Their products are designed to solve common cable management problems and improve cable organization. With their extensive range of products, [Name of Company] is a one-stop-shop for all your cable management needs.

Protect Your Hoses with Heat Resistant Sleeves

Heat Resistant Sleeve for Hose: A Solution to Protect Your MachineryMachinery and equipment are an essential part of modern life, and they require constant upkeep to function efficiently. When it comes to high-temperature applications like industrial pipes, hoses, and wires, they need to be protected from heat damage. The good news is that there is a solution for this - a heat resistant sleeve for hoses.{Company Name}, a leading manufacturer of high-quality thermal insulation products, has recently added a heat resistant sleeve for hoses to its product portfolio. The sleeve is designed to protect hoses, wires, and cables from temperatures up to 500°F (260°C), making it ideal for use in industries such as oil and gas, chemicals, and manufacturing.The heat resistant sleeve is made of high-quality materials that resist chemical degradation, ozone, and UV radiation. It is also abrasion-resistant and provides excellent insulation, reducing energy costs and increasing the lifespan of hoses and cables.{Company Name} ‘s heat resistant sleeve is highly flexible and easy to install, making it an ideal choice for retrofitting existing systems. The sleeve can be easily slipped over the hose or cable and secured with heat shrink tape, making it fast and reliable to install.One of the most significant advantages of using {Company Name}’s heat resistant sleeve is that it significantly reduces the risk of hose failure due to heat damage. Often, high-temperature applications result in hoses and cables getting brittle, cracked, or even melted. Such damage can cause leaks, system failures, and pose serious risks to workers and equipment. By using heat resistant sleeves, companies can protect their machinery and prevent such hazardous conditions from occurring.Heat resistant sleeve for hoses is an excellent investment for companies that value safety and efficiency. The sleeve not only offers protection against high temperatures but also extends the lifespan of hoses and cables, resulting in significant savings in replacement and maintenance costs.{Company Name}’s heat resistant sleeve for hoses is a product that meets the highest standards of safety and efficiency. It is designed to help companies reduce their carbon footprint and promote sustainable practices. As a premium insulation solutions provider, the company is committed to innovation, quality, and customer satisfaction.{Company Name} is a global leader in providing thermal insulation products that meet the requirements of diverse industries. The company offers a broad range of products, including heat resistant tapes, jackets, blankets, and sleeves. Their extensive product portfolio, along with their technical expertise, allows them to provide custom solutions tailored to each client’s unique requirements.In conclusion, the heat resistant sleeve for hoses offered by {Company Name} is a highly beneficial investment for companies that value safety, efficiency, and sustainability. The sleeve protects machinery and extends the lifespan of hoses and cables, which saves costs on replacements and maintenance. As a leading global provider of insulation solutions, {Company Name} is committed to providing innovative, high-quality, and reliable products that meet and exceed industry standards.

Flexible Metal Cable Sleeve: A Versatile Solution for Cable Management

In recent years, the use of flexible metal cable sleeves has become increasingly popular in the manufacturing industry due to their durability and versatility. One company that has been at the forefront of this trend is {brand name removed}.Founded in 1998, {brand name removed} has been providing innovative solutions for cable management and protection for over two decades. They offer a range of products, including metal and non-metallic conduit systems, cable trays, and flexible metal cable sleeves.{Brand name removed}'s flexible metal cable sleeves are made from stainless steel, making them resistant to corrosion and able to withstand harsh environmental conditions. They are also able to absorb high levels of shock and vibration, making them ideal for use in heavy-duty machinery and equipment.One of the main benefits of using {brand name removed}'s flexible metal cable sleeves is their flexibility and ease of installation. They can be easily bent and manipulated to fit any shape or size of cable, making them ideal for use in complex cable management systems.Another key advantage of using {brand name removed}'s flexible metal cable sleeves is their ability to provide enhanced protection against electromagnetic interference (EMI) and radio frequency interference (RFI). This is particularly important in industries such as aerospace and defense, where sensitive electronic equipment is used.{Brand name removed} also offers a range of customization options for their flexible metal cable sleeves, allowing customers to choose the length, diameter, and material that best suits their needs. This level of flexibility has made them a popular choice among manufacturers and OEMs.In addition to their flexible metal cable sleeves, {brand name removed} also offers a range of value-added services, including design, prototyping, and engineering support. Their team of experienced engineers are able to work closely with customers to develop customized solutions that meet their unique requirements.{Brand name removed}'s commitment to quality is illustrated by their ISO 9001:2015 certification, which ensures that all of their products are manufactured to the highest standards.Overall, {Brand name removed}'s flexible metal cable sleeves are a reliable and cost-effective solution for cable management and protection. With their ability to provide enhanced protection against EMI and RFI, as well as their flexibility and ease of installation, they are an ideal choice for a wide range of industries and applications.

Braided Cable Sheath: Enhancing Protection and Durability

Title: Innovative Braided Cable Sheath Enhances Durability and FunctionalityIntroduction:In today's fast-paced and interconnected world, cables have become an integral part of our lives, facilitating seamless connectivity and powering a wide range of devices. As technology evolves, there is a growing need for cables that can withstand the demands of daily use, offering enhanced durability without compromising on functionality. This is where the innovative Braided Cable Sheath, developed by an industry-leading company, comes into play. With its unique design and advanced features, this cable sheath is set to revolutionize the market.Body:1. Overview of Braided Cable Sheath:The Braided Cable Sheath, a creation of a renowned company, is engineered to provide a robust and long-lasting solution for cable protection. This innovative sheath adopts a braided design, ensuring superior flexibility and durability compared to traditional cable housing. By combining high-quality materials with cutting-edge manufacturing techniques, this cable sheath delivers exceptional performance in challenging environments.2. Unmatched Durability:One of the standout features of the Braided Cable Sheath is its remarkable durability. The blend of high-tensile strength materials and a tightly woven braided pattern creates a protective barrier that safeguards cables against abrasion, bending, and impacts. This means that users can rely on these cables even in high-stress situations, both indoors and outdoors, ensuring uninterrupted connectivity.3. Enhanced Functionality:Beyond its durability, the Braided Cable Sheath offers several features that enhance functionality and user experience. With its remarkable flexibility, the sheath allows for easy cable management, minimizing tangles and knots. Moreover, the braided design dissipates heat efficiently, preventing overheating issues often associated with prolonged use of cables. This not only improves the lifespan of the cables but also provides a safe and reliable connection for users.4. Versatility:The Braided Cable Sheath is designed to cater to a wide range of applications. Its adaptability allows it to be used in various industries, including consumer electronics, telecommunications, automotive, and aerospace. Whether it is used for charging cables, data transfer cables, or audio-video connections, this versatile sheath ensures optimal performance and longevity.5. Industry-leading Standards:The company behind the Braided Cable Sheath is well-known for its commitment to adherence to industry standards. The sheath undergoes rigorous testing to meet and exceed the highest quality requirements, ensuring that each product is reliable, safe, and long-lasting. Additionally, with a dedicated team of experts and engineers, the company implements continuous research and development efforts to stay ahead of evolving technological needs.6. Eco-conscious Manufacturing:In an era of environmental awareness, it is encouraging to note that the Braided Cable Sheath is manufactured with sustainability in mind. The company employs eco-friendly practices throughout the production process, minimizing waste generation and utilizing recyclable materials. By choosing these innovative cable sheaths, users can contribute to a greener future.Conclusion:The introduction of the Braided Cable Sheath marks a significant advancement in cable protection technology. With its unbeatable durability, enhanced functionality, versatility, and adherence to industry standards, this innovative sheath is set to become the go-to choice for various sectors. As technology continues to evolve, the Braided Cable Sheath ensures that cables keep pace with the demands of modern connectivity while offering a reliable and long-lasting solution.

The Benefits of Using Fiberglass Cloth for Various Applications

In recent years, there has been an increased demand for high-quality and durable materials that can withstand the test of time. Fiberglass cloth is one such material that has become increasingly popular, especially in the construction and automotive industries. This versatile material is known for its strength, flexibility, and resistance to heat and corrosion, making it an ideal choice for a wide range of applications.One company that has been at the forefront of producing fiberglass cloth is Company X (name removed for confidentiality). Founded in 1990, Company X has grown to become one of the leading manufacturers of fiberglass cloth in the world. Their state-of-the-art production facilities and advanced production processes have helped them produce high-quality fiberglass cloth that meets the diverse needs of their customers.Fiberglass cloth is made by weaving thick strands of glass fibers together to create a strong and flexible fabric. This fabric is then coated with a resin or polyester material to give it added durability and strength. This combination of glass fibers and resin creates a material that is lightweight, yet extremely strong and durable. Unlike other materials such as steel or aluminum, fiberglass cloth is highly resistant to corrosion and is resistant to fire, making it an ideal choice for use in harsh or dangerous environments.Company X produces a wide range of fiberglass cloth for various applications such as pipe insulation, fireproof curtains, electrical insulation, and automotive parts. They have a team of experienced professionals who are dedicated to ensuring that their customers receive the best quality products and services.One of the advantages of using fiberglass cloth is its versatility. It can be easily molded and shaped into any form, making it ideal for use in complex structures such as the hull of a boat or the body of an airplane. Its flexibility also makes it an ideal choice for use in insulation, where it can be easily wrapped around pipes and other structures to provide heat and sound insulation.Another advantage of using fiberglass cloth is its low environmental impact. Unlike other materials such as steel or aluminum, fiberglass cloth does not require the use of natural resources such as ore or coal, making it a more sustainable choice. Additionally, fiberglass cloth is highly recyclable, meaning that it can be reused or repurposed at the end of its life cycle, further reducing its environmental impact.Company X is committed to sustainability and has invested heavily in eco-friendly production processes and materials. Their fiberglass cloth products are manufactured using recycled materials and their production facilities are designed to reduce emissions and waste.In conclusion, fiberglass cloth is a versatile material that has become increasingly popular in various industries due to its durability, strength, and versatility. Company X has established itself as one of the leading manufacturers of fiberglass cloth in the world, thanks to their commitment to quality and sustainability. As the demand for high-quality and sustainable materials continues to grow, fiberglass cloth will undoubtedly remain a top choice for a wide range of applications.

Discover the Benefits of Fiberglass Sleeving for Electrical Applications

[Company Introduction][Company Name] is a leading manufacturer and supplier of high-quality industrial materials. With over [number] years of experience in the industry, we strive to provide our customers with innovative solutions and top-notch products.Our commitment to excellence and customer satisfaction has earned us the trust and loyalty of businesses worldwide. We take pride in our extensive range of products, which includes [product categories]. From electrical insulation materials to mechanical protection solutions, we cater to various industries, meeting their diverse needs and requirements.Our state-of-the-art manufacturing facility, equipped with cutting-edge technology and skilled professionals, ensures that our products are of the highest standard. With a strong emphasis on quality control measures, we conduct rigorous testing at every stage of the production process to ensure optimal performance and reliability.At [Company Name], we believe in sustainable practices and responsible manufacturing. We are committed to minimizing our environmental impact and continuously improving our processes to adopt greener alternatives. Our dedication to sustainability extends to the materials we use, including our range of Fibreglass Sleeving.[Introduction to Fibreglass Sleeving]Fibreglass Sleeving is a versatile and highly durable electrical insulation material that finds applications across various industries. Designed to safeguard electrical components from heat, chemicals, and abrasions, this sleeving provides dependable protection in demanding environments.Key Features of Fibreglass Sleeving:1. High Temperature Resistance: Fibreglass Sleeving is known for its exceptional resistance to high temperatures. This makes it suitable for use in applications where prolonged exposure to heat is expected, such as in motors, transformers, and generators.2. Electrical Insulation: The insulating properties of Fibreglass Sleeving make it ideal for electrical applications, where it effectively prevents current leakage and enhances safety. It ensures the efficient functioning of electrical systems, minimizing the risk of shorts and malfunctions.3. Chemical Resistance: Fibreglass Sleeving demonstrates excellent resistance to a wide range of chemicals, making it an ideal choice for industries that deal with corrosive substances. It provides a protective layer that shields electrical components from chemical damage, extending their lifespan.4. Mechanical Protection: The robust nature of Fibreglass Sleeving offers mechanical protection to wires and cables. It resists wear and tear caused by abrasion, thereby ensuring the longevity of the components and enhancing their reliability.5. Flexibility and Expandability: Fibreglass Sleeving is available in various sizes and configurations, allowing for easy installation and fitting onto different wire diameters. Its expandability ensures a snug fit, offering excellent coverage and protection.Applications of Fibreglass Sleeving:1. Electrical Equipment: Fibreglass Sleeving is widely used in electrical equipment, including motors, generators, transformers, and coils. It ensures insulation, protection, and heat resistance in these critical components.2. Automotive Industry: The automotive industry heavily relies on Fibreglass Sleeving for wire harnessing and insulation purposes. It provides a reliable barrier against heat, abrasion, and chemicals, thereby enhancing the performance and safety of vehicles.3. Electronic Appliances: Fibreglass Sleeving is utilized in electronic appliances such as kitchen appliances, televisions, and computers. It safeguards wiring connections and electrical components from heat and abrasions caused by regular usage.4. Industrial Applications: Various industrial sectors, such as aerospace, manufacturing, and telecommunications, benefit from Fibreglass Sleeving. Its high temperature resistance, electrical insulation, and durability make it a preferred choice for protecting wires and cables in these demanding environments.In conclusion, Fibreglass Sleeving offered by [Company Name] is a reliable and efficient choice for electrical insulation and mechanical protection. With its exceptional performance under high temperatures, chemical resistance, and flexibility, this sleeving ensures the long-term reliability of electrical components in various industries. At [Company Name], we strive to provide our customers with superior products backed by our dedication to quality and sustainability.