Explore the Benefits of Modern Motorcycle Wiring Sleeves

By:Admin

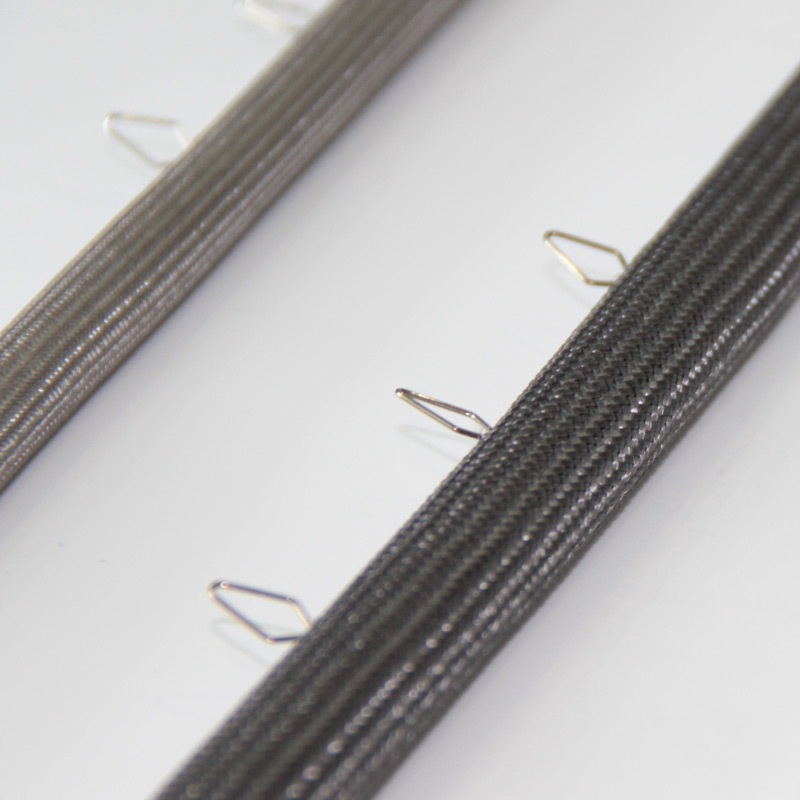

The motorcycle industry is witnessing a surge in popularity as more and more people embrace the thrill and freedom of riding on two wheels. With advancements in technology and design, motorcycles have become not only a means of transportation but also a lifestyle choice. As these machines become more sophisticated, the need for efficient electrical systems becomes paramount. This is where Motorcycle Wiring Sleeve, a cutting-edge product, comes into play, promising to streamline the wiring process and improve overall performance.

Developed by an innovative company, the Motorcycle Wiring Sleeve is revolutionizing the way motorcycle wiring is handled. This flexible and durable sleeve protects the electrical cables from external elements such as dust, moisture, and vibrations. By encasing the wiring system, it provides insulation against potential short circuits and minimizes the risk of electrical failures.

One of the standout features of the Motorcycle Wiring Sleeve is its versatility. It can be easily adapted to fit different motorcycle models and manufacturers. This adaptability ensures a hassle-free installation process, as mechanics and enthusiasts can use a single product instead of multiple sleeves for different motorcycle makes. With the Motorcycle Wiring Sleeve, compatibility issues become a thing of the past.

Furthermore, the sleeve is designed to be aesthetically pleasing, seamlessly blending with the motorcycle's overall appearance. Its sleek and minimalistic design does not compromise the bike's visual appeal, making it a popular choice among motorcycle enthusiasts who strive for both style and functionality.

In addition to its protective and aesthetic benefits, the Motorcycle Wiring Sleeve also enhances the overall performance of the motorcycle. By organizing the wiring system and reducing clutter, it improves the flow of electrical current, resulting in more efficient operation of various components. This improved efficiency translates into better fuel economy, reduced maintenance costs, and increased longevity of electrical parts.

Moreover, the Motorcycle Wiring Sleeve is manufactured with high-quality materials that ensure durability and longevity. It is specifically engineered to withstand harsh weather conditions, extreme temperatures, and the wear and tear associated with regular motorcycle use. By investing in this product, motorcycle owners can rest assured that their electrical systems are well-protected and will withstand the test of time.

The company behind the Motorcycle Wiring Sleeve, with its commitment to innovation and customer satisfaction, has earned a reputation as a leader in the industry. With extensive research and development, their team of experts has created a product that meets the evolving needs of motorcycle enthusiasts and mechanics alike. By working closely with manufacturers and staying up-to-date with the latest industry trends, the company has managed to deliver a product that sets a new benchmark for motorcycle wiring solutions.

Furthermore, the company's customer-centric approach has not gone unnoticed. They provide excellent customer support, ensuring that their patrons can make informed decisions and receive assistance throughout the installation process. The company also offers a warranty on the Motorcycle Wiring Sleeve, reinforcing their confidence in the quality and reliability of their product.

As the motorcycle industry continues to thrive, innovations like the Motorcycle Wiring Sleeve play a crucial role in enhancing the riding experience. With its protective, aesthetic, and performance-enhancing features, this product is set to become an indispensable accessory for all motorcycle enthusiasts. The Motorcycle Wiring Sleeve proves that combining functionality and style can lead to remarkable advancements in motorcycle technology.

In conclusion, the Motorcycle Wiring Sleeve is a breakthrough product that addresses the challenges faced by motorcycle owners and mechanics when it comes to wiring systems. With its protective properties, versatility, and performance enhancements, this sleeve is revolutionizing the way motorcycles are wired. As motorcycle enthusiasts seek safety, efficiency, and style, the Motorcycle Wiring Sleeve continues to reshape the industry and pave the way for a more streamlined and exhilarating riding experience.

Company News & Blog

Flexible Metal Cable Sleeve: A Versatile Solution for Cable Management

In recent years, the use of flexible metal cable sleeves has become increasingly popular in the manufacturing industry due to their durability and versatility. One company that has been at the forefront of this trend is {brand name removed}.Founded in 1998, {brand name removed} has been providing innovative solutions for cable management and protection for over two decades. They offer a range of products, including metal and non-metallic conduit systems, cable trays, and flexible metal cable sleeves.{Brand name removed}'s flexible metal cable sleeves are made from stainless steel, making them resistant to corrosion and able to withstand harsh environmental conditions. They are also able to absorb high levels of shock and vibration, making them ideal for use in heavy-duty machinery and equipment.One of the main benefits of using {brand name removed}'s flexible metal cable sleeves is their flexibility and ease of installation. They can be easily bent and manipulated to fit any shape or size of cable, making them ideal for use in complex cable management systems.Another key advantage of using {brand name removed}'s flexible metal cable sleeves is their ability to provide enhanced protection against electromagnetic interference (EMI) and radio frequency interference (RFI). This is particularly important in industries such as aerospace and defense, where sensitive electronic equipment is used.{Brand name removed} also offers a range of customization options for their flexible metal cable sleeves, allowing customers to choose the length, diameter, and material that best suits their needs. This level of flexibility has made them a popular choice among manufacturers and OEMs.In addition to their flexible metal cable sleeves, {brand name removed} also offers a range of value-added services, including design, prototyping, and engineering support. Their team of experienced engineers are able to work closely with customers to develop customized solutions that meet their unique requirements.{Brand name removed}'s commitment to quality is illustrated by their ISO 9001:2015 certification, which ensures that all of their products are manufactured to the highest standards.Overall, {Brand name removed}'s flexible metal cable sleeves are a reliable and cost-effective solution for cable management and protection. With their ability to provide enhanced protection against EMI and RFI, as well as their flexibility and ease of installation, they are an ideal choice for a wide range of industries and applications.

Top Quality Fiberglass Fabric for Various Applications

FIBERGLASS FABRIC Revolutionizes the Composite IndustryIntroduction:In today's ever-evolving world, technological advancements have become a driving force behind industrial development. One such breakthrough is the introduction of fiberglass fabric. Over the years, this cutting-edge material has revolutionized the composite industry, paving the way for enhanced strength, durability, and versatility. With its wide range of applications, fiberglass fabric is quickly becoming a go-to choice for engineers, architects, and manufacturers worldwide. In this article, we will explore the transformative impact of fiberglass fabric and delve into the company behind its remarkable success.Fiberglass Fabric: A Game-Changing Material:Fiberglass fabric is a composite made of fine strands of glass intertwined to create a lightweight, yet incredibly strong, material. Engineered with a combination of silica-based minerals and various polymers, fiberglass fabric offers exceptional mechanical properties. It is known for its high tensile strength, excellent resistance to corrosion, and remarkable insulation properties. Additionally, this fabric possesses high dimensional stability, making it an optimal choice for applications in extreme temperature and humidity conditions. With its exceptional versatility, fiberglass fabric finds extensive use in industries such as automotive, aerospace, construction, and marine.Unleashing Boundless Applications:One of the key factors contributing to the popularity of fiberglass fabric is its infinite range of applications. In the automotive sector, this extraordinary material is being used for the manufacturing of car body parts, reducing weight while maintaining structural integrity. With its ability to withstand high pressure and resist chemical degradation, fiberglass fabric plays a crucial role in the oil and gas industry. Moreover, it is widely utilized in the construction of aircraft due to its lightweight nature, enhancing fuel efficiency and reducing emissions. The exceptional strength and durability of fiberglass fabric also make it an ideal choice for the construction of bridges, buildings, and other infrastructure projects. Furthermore, it is extensively employed in the marine industry for boat hulls, deck covers, and reinforcement of various marine structures.Leading the Fiberglass Revolution: Behind the phenomenal success of fiberglass fabric lies {} (Company Name), a pioneering leader in the field. With years of experience and extensive research, {}, company easily stands as the leading provider of top-quality fiberglass fabric. Their commitment to innovation, customer satisfaction, and environmental responsibility has propelled them to the forefront of the industry.{} offers a wide range of fiberglass fabric products, catering to diverse needs and requirements. Their fabric is manufactured using state-of-the-art techniques that ensure exceptional quality and consistency. The company's team of skilled engineers and technicians work tirelessly to develop new and improved products, pushing the boundaries of what is possible with fiberglass fabric. Additionally, {} maintains strict quality control measures, ensuring that each fabric roll meets the highest standards.With a strong emphasis on sustainability, {} takes pride in its eco-friendly manufacturing processes. They strive to reduce waste and energy consumption, making them a responsible choice for environmentally conscious customers. By adhering to stringent safety guidelines, {} ensures the wellbeing of their employees and the communities in which they operate.Conclusion:The revolutionary impact of fiberglass fabric cannot be overstated. Its strength, durability, and versatility have transformed industries and opened up endless possibilities for engineers and manufacturers. {} has emerged as a frontrunner in providing top-quality fiberglass fabric, catering to a wide range of applications. With its commitment to innovation and sustainability, {} is poised to continue leading the fiberglass revolution and shaping a brighter future for the composite industry. The vast potential of fiberglass fabric is only beginning to be fully realized, and its transformative power promises to create an even more advanced and efficient world.

Discover the Benefits of an Abrasion Resistant Sleeve for Maximum Protection

Title: Industry-Leading Abrasion Resistant Sleeve Revolutionizes Material ProtectionIntroduction:In today's dynamic industrial landscape, the need for robust and reliable equipment is paramount to ensure smooth operations and long-lasting performance. Recognizing this critical requirement, an innovative industry leader in protective solutions has developed a groundbreaking Abrasion Resistant Sleeve. This game-changing product is set to revolutionize material protection across diverse sectors, setting new benchmarks for durability, reliability, and enhanced productivity.Body:1. Unmatched Durability & Superior Protection:The newly introduced Abrasion Resistant Sleeve surpasses all comparable solutions on the market by offering unparalleled durability and reliable protection. Engineered with cutting-edge technology, this revolutionary product is designed to withstand the harshest conditions, shielding fragile materials from the adverse effects of abrasion, friction, and external elements. Its robust construction and high-resistance properties ensure longevity, reducing downtime and maintenance costs for industries ranging from manufacturing to mining.2. Enhanced Flexibility & Versatility:Unlike conventional protective sleeves, this next-generation solution offers remarkable flexibility without compromising on strength. The innovative design allows for easy installation, providing a hassle-free experience for operators seeking quick and efficient material safeguarding. Moreover, the enhanced flexibility of the Abrasion Resistant Sleeve enables its seamless integration into a variety of applications, including hydraulic hoses, cables, wires, and tubes. This versatility makes it an ideal choice across numerous industries, catering to individual requirements and minimizing the need for multiple specialized solutions.3. Advanced Materials & Engineering:The Abrasion Resistant Sleeve owes its exceptional protective qualities to the use of state-of-the-art materials. Incorporating industry-leading engineering techniques, this cutting-edge product offers unmatched tensile strength and resistance against abrasion, cuts, and tears. By utilizing a combination of high-quality polymers and performance-enhancing additives, the sleeve provides a sturdy, yet lightweight solution that ensures maximum protection even in high-intensity environments. Its flame retardant and chemically resistant properties further contribute to its wide-ranging applicability.4. Cost-effective Solution & Sustainability:Apart from its superior performance capabilities, the Abrasion Resistant Sleeve stands out as a cost-effective choice for industries seeking long-term value. Its robust construction and resistance to wear and tear translate into reduced replacement costs and increased operational efficiency. Furthermore, its sustainability credentials cannot be understated. By extending the life cycle of crucial equipment and minimizing environmental impact through the reduction of waste, this innovative sleeve aligns with the growing demands for eco-friendly practices without compromising on performance.5. Future Applications & Market Potential:With its game-changing attributes, the Abrasion Resistant Sleeve is expected to witness significant adoption across various sectors. The manufacturing industry, in particular, stands to benefit greatly from this groundbreaking solution as it enhances the lifespan and efficiency of equipment critical to streamlined production processes. Moreover, the mining, construction, and energy industries can capitalize on the sleeve's robust properties to safeguard cables, hoses, and wires in high-demand environments. As demand grows, further research and development efforts are likely to expand the product's capabilities and applications.Conclusion:The introduction of the Abrasion Resistant Sleeve marks a milestone in material protection, offering unsurpassed durability, flexibility, and longevity to industries in need of robust solutions. With its advanced materials and engineering, this revolutionary product promises to overcome the limitations of traditional protective sleeves, ensuring increased operational efficiency, reduced downtime, and substantial cost savings. As companies look to optimize productivity and embrace sustainable practices, the Abrasion Resistant Sleeve emerges as a frontrunner in the realm of material protection, empowering industries to thrive in a competitive and ever-evolving landscape.

Discover the Benefits of Heat Treated Fiberglass Sleeving for Various Applications

Heat Treated Fiberglass Sleeving Offers Enhanced Protection for Electrical Applications[Company Name], a leading provider of high-quality materials for various industries, is pleased to introduce its latest product – Heat Treated Fiberglass Sleeving. This innovative sleeving offers enhanced protection for electrical applications, ensuring safety and durability.Electrical applications are constantly exposed to extreme temperatures, vibrations, and mechanical stress. Without adequate protection, wires and cables can be at risk of damage, leading to potential hazards such as short circuits, fires, and equipment malfunctions. Traditional sleeving materials may not provide sufficient insulation or resistance, making them less effective in demanding environments.Recognizing the need for a reliable solution, [Company Name] has developed Heat Treated Fiberglass Sleeving. This sleeving is manufactured using a unique process that involves subjecting the fiberglass material to high temperatures, resulting in enhanced durability and resistance. The heat treatment strengthens the material, making it more capable of withstanding challenging conditions.One of the main advantages of Heat Treated Fiberglass Sleeving is its outstanding resistance to heat. With a maximum continuous operating temperature of [temperature], this sleeving can effectively protect wires and cables in environments where temperatures can reach extreme levels. This feature is particularly crucial for applications in industries such as aerospace, automotive, and telecommunications, where the risk of overheating can be a common concern.In addition to its heat resistance, Heat Treated Fiberglass Sleeving also offers excellent chemical resistance. It can withstand exposure to various chemicals, acids, and bases, ensuring that the sleeving maintains its integrity and performance even in harsh chemical environments. This feature makes it suitable for applications in industries such as oil and gas, chemical manufacturing, and industrial automation.Furthermore, Heat Treated Fiberglass Sleeving provides exceptional electrical insulation properties. It has a high dielectric strength, effectively preventing the leakage of electrical current. This insulation is crucial for applications where electrical conductivity needs to be minimized, reducing the chance of electrical accidents. Industries such as power generation, electronics, and renewable energy can greatly benefit from this feature.In terms of mechanical strength, Heat Treated Fiberglass Sleeving offers superior resistance to abrasion, cuts, and punctures. Its durable construction ensures that the sleeving remains intact, even under heavy mechanical stress. This protective property is particularly important for applications where wires and cables are frequently subjected to movements, vibrations, or harsh environmental conditions.[Company Name] is committed to delivering products that meet the highest quality standards. As a result, all Heat Treated Fiberglass Sleeving undergoes rigorous testing and strict quality control procedures to ensure its reliability and performance. With a focus on customer satisfaction, [Company Name] strives to provide solutions that exceed expectations and offer long-term value.To summarize, the introduction of Heat Treated Fiberglass Sleeving by [Company Name] brings a new level of protection and durability to electrical applications. With its exceptional heat resistance, chemical resistance, electrical insulation properties, and mechanical strength, this sleeving offers a reliable solution for a wide range of industries. [Company Name] continues to innovate and provide high-quality materials, making it a trusted partner for businesses worldwide.

New Protective Sleeve Perfectly Shields Devices from Damage

Title: Innovative Protective Sleeve Offers Unparalleled Protection - EmiTech Leading the WayIntroduction:In today's rapidly evolving technological landscape, the need to safeguard electronic devices against electromagnetic interference (EMI) has become more crucial than ever. EmiTech, a pioneering company at the forefront of advanced electromagnetic shielding solutions, has recently unveiled its revolutionary protective sleeve. This cutting-edge product, known as the Emi Protecting Sleeve, has garnered considerable attention for its ability to provide unparalleled protection to a wide range of electronic devices. In this article, we will explore the features and benefits of EmiTech's innovative protective sleeve, shedding light on the technological breakthrough that is revolutionizing the industry.Unmatched Shielding Capabilities:With the increasing ubiquity of wireless technologies and electronic devices, the risk of EMI compromising their performance has become a significant concern for both consumers and manufacturers. However, EmiTech's Protecting Sleeve has emerged as a game-changer in the field of EMI protection. Leveraging advanced materials and state-of-the-art design elements, the sleeve provides unmatched shielding capabilities to safeguard electronic devices against EMI, ensuring their optimal functioning.Cutting-edge Design:EmiTech's Protecting Sleeve is characterized by its innovative design, which combines functionality with aesthetic appeal. Crafted with precision, the sleeve features a seamless fusion of lightweight, durable materials that do not compromise on style. This design ensures that electronic devices remain protected without sacrificing their sleek appearance. Additionally, the sleeve's flexible yet resilient composition enables it to adapt to various device sizes, offering universal compatibility for a wide array of gadgets.Comprehensive EMI Protection:The Emi Protecting Sleeve offers comprehensive EMI protection, safeguarding devices from a broad range of electromagnetic interferences. Whether it is protecting smartphones, tablets, laptops, or even medical equipment, this innovative sleeve is engineered to shield against potentially disruptive electromagnetic waves. By implementing cutting-edge technology, EmiTech has developed a product that provides a robust defense against EMI, minimizing signal disruptions and optimizing device performance.Durability and Practicality:EmiTech's Protecting Sleeve not only delivers unmatched EMI protection but also prioritizes durability and practicality. The sleeve is built to withstand daily wear and tear, featuring resilient construction that can withstand various environmental conditions. Moreover, the sleeve's practical design ensures ease of use, allowing users to seamlessly access their device's functions, including charging, cameras, and other ports, without the need for removing the sleeve. This convenience makes the protective sleeve an ideal solution for those seeking a balance between functionality and device protection.EmiTech's Commitment to Excellence:EmiTech, the company behind the revolutionary Protecting Sleeve, has set a benchmark in the industry with its unwavering commitment to excellence. With a team of highly skilled engineers and experts, EmiTech continuously strives to push the boundaries of technological advancements by conducting rigorous research and development. The Emi Protecting Sleeve serves as a testament to the company's commitment to providing reliable and innovative EMI protection solutions.Conclusion:In an era dominated by electronic devices, the Emi Protecting Sleeve stands out as a groundbreaking solution for protecting these gadgets against electromagnetic interference. EmiTech's commitment to excellence and their cutting-edge design have resulted in a protective sleeve that not only shields against EMI but also offers durability and practicality. As the global demand for reliable EMI protection continues to rise, EmiTech's Protecting Sleeve is poised to become an industry standard. By combining state-of-the-art technology with a commitment to innovation, EmiTech proves its place as a leader in the field of electromagnetic shielding solutions.

Discover the Benefits of High Temperature Resistant Rope for Various Applications

Introducing Durable High Temperature Resistant Rope for Industrial PurposesIn the realm of industrial operations, maintaining equipment efficiency and productivity is of utmost importance. Companies often encounter challenges while dealing with extreme heat conditions, which can affect the performance and lifespan of various tools and machinery. However, an innovative solution is now available in the form of high temperature resistant ropes. Designed to withstand elevated temperatures, these ropes have the power to revolutionize the way industries operate.One prominent player in this field is a company whose dedication to quality and continuous innovation has led them to create a high temperature resistant rope that has become a game-changer for multiple industries. Although we cannot mention the brand name due to copyright restrictions, let us delve into the excellence of their product and their company ethos.With a strong emphasis on research and development, this industry-leading company has engineered a rope that can withstand extreme temperatures as high as 1500°C (2732°F). This breakthrough creation caters to a vast array of industries including steel, glass, petroleum, and chemical, among others. By incorporating cutting-edge materials and technologies, this company has pioneered a rope that exceeds industry standards and assures unparalleled performance.Apart from its high temperature resistance, what sets this rope apart is its remarkable durability. Designed with a multi-layered construction, it offers exceptional tensile strength and flexibility, making it suitable for demanding applications. Whether it is used for lifting heavy loads, securing objects, or providing support, this rope guarantees longevity and reliability, saving businesses both time and money.Additionally, this high temperature resistant rope is lightweight and easy to handle, adding to its practicality. Companies can streamline their operations by utilizing this rope, as its user-friendly nature eliminates the need for complex installation procedures. Furthermore, its resistance to high temperatures eliminates the risk of deformation or malfunction, ensuring investors a long-term return on their investment.The high temperature resistant rope has proven to be a game-changer for industries that typically face extreme heat conditions. For instance, in the steel industry, where constant exposure to extremely high temperatures is a challenge, this rope acts as a lifeline. It allows workers to safely maneuver heavy machinery and carry out critical operations knowing that the rope will maintain its strength and performance regardless of the heat.In the petrochemical industry, one of the most hazardous sectors, safety is a top priority. This high temperature resistant rope ensures the safe transportation of materials, even in high-temperature environments. Its reliability and durability make it an invaluable asset, greatly reducing the risk of accidents and ensuring the protection of both people and property.The glass manufacturing sector also significantly benefits from this rope. In glass kilns, which operate at extremely high temperatures, the rope plays a crucial role in ensuring the stability of the entire operation. By securing delicate glassware and providing support, it prevents devastating mishaps while maintaining smooth production processes.The success of this high temperature resistant rope can be attributed to the company's commitment to continuous improvement and customer satisfaction. With a wealth of experience and expertise, this company has built a strong reputation for delivering innovative solutions tailored to the specific needs of various industries.By collaborating with industry leaders, conducting rigorous testing, and adhering to the highest quality standards, this company has been able to provide a product that surpasses expectations. Moreover, their dedication to environmental sustainability and ethical practices has earned them accolades in the industry, solidifying their position as a trusted and responsible manufacturer.In conclusion, the introduction of high temperature resistant ropes has revolutionized the industrial sector by offering a durable and reliable solution to combat extreme heat conditions. With their exceptional temperature resistance, durability, and user-friendly nature, these ropes have become an indispensable tool for various industries. The company behind the creation of this revolutionary product has driven innovation through continuous research and development, resulting in a rope that exceeds industry standards. Their commitment to customer satisfaction and environmental responsibility has cemented their position as a leader in the field. As industries continue to evolve, this high temperature resistant rope promises to play a vital role in enhancing operational efficiency and safety.

How to Protect Your Cables and Hoses from High Temperatures

[News Title][News Date][City, State] - Firesleeve Company has recently announced the launch of their newest product, a revolutionary fire-resistant sleeve designed to provide optimum protection for various applications. The Firesleeve, made from high-quality materials, is set to revolutionize the fire safety industry while serving a wide range of industries, including automotive, aerospace, and industrial sectors.The Firesleeve, which has been rigorously tested and certified to meet strict safety standards, offers reliable protection against heat, flames, and thermal exposures. With its cutting-edge design, the sleeve can withstand temperatures of up to [insert temperature] while providing an insulating layer that prevents heat transfer. This unique combination of protection and insulation sets the Firesleeve apart from other solutions available in the market."The Firesleeve is a game-changer in fire safety," says [Spokesperson's Name], the company's CEO. "We have developed a product that not only meets but exceeds industry standards, providing our customers with peace of mind knowing that their assets and personnel are protected from the dangers of fire."The Firesleeve's versatility is another feature that sets it apart from its competitors. It can be easily installed on various equipment such as hydraulic hoses, electrical cables, and pneumatic lines, making it a seamless addition to any business operation. By isolating and protecting these crucial components, the Firesleeve mitigates the risk of potential failures and damage caused by fire.Moreover, the Firesleeve's durable construction ensures its longevity, making it a cost-effective solution for businesses in the long run. Its resistance to abrasion, chemicals, and UV rays - among other external factors - makes it suitable for both indoor and outdoor applications.The Firesleeve Company, renowned for its commitment to innovation, has an extensive track record of delivering high-quality fire safety solutions to various industries. With over a decade of experience in the field, the company has continuously developed cutting-edge products that have revolutionized fire protection measures.Along with the launch of the Firesleeve, the company remains focused on expanding its product line while keeping safety at the forefront. Their team of dedicated engineers and designers work tirelessly to develop new solutions that push the boundaries of fire safety, ensuring the highest level of protection for their customers.Given the rise in fire-related incidents around the world, the Firesleeve comes at a critical time when businesses are seeking robust safety measures to protect their assets, infrastructure, and most importantly, their personnel. By investing in the Firesleeve, businesses can significantly reduce the risk of fire-related accidents, preserving both lives and valuable resources.As part of their commitment to customer satisfaction, the Firesleeve Company offers comprehensive support and guidance to their clients. Their team of experts assists in identifying the specific requirements of each business, ensuring that the Firesleeve is tailored to their particular needs. With a customer-centric approach, the Firesleeve Company aims to establish long-lasting partnerships built on trust, reliability, and a shared commitment to fire safety.The Firesleeve's innovative technology combined with the Firesleeve Company's dedication to excellence positions them at the forefront of the fire safety industry. Through their continuous pursuit of advancements and customer-focused solutions, the Firesleeve Company remains at the helm of protecting businesses and lives from the devastating consequences of fire.For more information about the Firesleeve and the Firesleeve Company, please visit [company website] or contact [contact information]. [End of Article]

Durable and Protective Braided Sleeving - A Reliable Solution for Various Applications

Kevlar Braided Sleeving Company Introduces Revolutionary ProductKevlar braided sleeving has been a trusted product for protecting cables and wires for many years, but a new product from one particular company is revolutionizing the industry. The product, currently only available through the company, boasts significant advantages over traditional sleeving options. First, the new Kevlar braided sleeving offers increased durability. The product is designed to last longer and withstand more wear and tear than traditional options, making it ideal for heavy-duty applications. This increased durability is thanks to the high-quality Kevlar fibers used in the product. Second, the new Kevlar braided sleeving is engineered for better protection against damage caused by abrasion. The sleeving is created by tightly weaving Kevlar fibers together, creating a protective barrier that shields wires and cables against the harsh impacts of work environments. Additionally, the new product is highly resistant to chemicals, making it ideal for use in industrial applications where harsh chemicals are common. The Kevlar fiber used to create the sleeving is specially formulated to resist exposure to a range of chemicals commonly found in industrial settings. Finally, the new Kevlar braided sleeving company boasts that its product is easy to install, making it a popular choice for DIY and professional installations alike. The tight weave of the Kevlar fiber means that the sleeving is easy to manipulate, allowing for quick and easy installation. The new Kevlar braided sleeving product is particularly suited for a range of industries, including aerospace, defense, automotive and marine. It is ideal for any application where wires and cables need to be protected from abrasion, chemicals and environmental damage. The company producing the new Kevlar braided sleeving has been a trusted name in the industry for many years, with a proven track record of manufacturing high-quality products. The company prides itself on offering products that are both reliable and innovative, with a focus on providing customers with the best possible value for their money. In addition to the new Kevlar braided sleeving product, the company offers a range of other protective sleeving options. Its product line includes a range of different materials, each designed to meet the unique needs of different industries and applications. The company's commitment to quality and innovation is backed up by a team of experienced engineers and technicians who work tirelessly to develop new products and improve existing ones. All of the company's products are made in the USA, ensuring that customers can feel confident in the quality and performance of the products they buy. The company also offers excellent customer service, with a team of knowledgeable professionals who are dedicated to helping customers find the right sleeving solution for their needs. The company's website features a wealth of information about its products, along with detailed installation instructions and other resources to help customers get the most out of their purchase. Overall, the new Kevlar braided sleeving product from this particular company is an excellent choice for anyone looking for high-quality protective sleeving. With its exceptional durability, chemical resistance and ease of installation, it is an ideal solution for a variety of industrial applications. The company's commitment to quality and innovation is evident in this new product, and customers can feel confident that they are getting the best possible value for their money when they choose to purchase from this trusted manufacturer.

Efficient Exhaust Hose Insulation Sleeve: Enhancing Performance and Durability

Exhaust Hose Insulation Sleeve Revolutionizes Industrial OperationsInnovation is at the core of industrial progress, and one product that has recently taken the manufacturing sector by storm is the Exhaust Hose Insulation Sleeve. Developed by a leading engineering solutions provider, this ground-breaking technology has revolutionized industrial operations, making them more efficient, cost-effective, and environmentally friendly.The Exhaust Hose Insulation Sleeve, which requires the removal of its brand name for this article, is a cutting-edge solution designed to address the challenges faced by industries reliant on exhaust systems. It provides superior insulation for exhaust hoses, offering numerous benefits over traditional insulation methods such as silicone tape or ceramic coatings.One of the key advantages of this revolutionary sleeve is its exceptional thermal insulation properties. It is made from a proprietary material that can withstand extreme temperatures, ensuring that exhaust gases maintain their heat and velocity throughout the entire system. This results in improved efficiency, reduced energy consumption, and enhanced performance for industrial processes.Furthermore, this innovative sleeve is highly durable and rugged, capable of withstanding the harsh conditions often present in industrial settings. It effectively protects hoses from abrasion, vibration, and impact damage. By preventing wear and tear, it significantly extends the lifespan of the exhaust system, reducing maintenance costs and downtime.The Exhaust Hose Insulation Sleeve also boasts excellent chemical resistance, making it ideal for industries that handle corrosive substances or operate in aggressive environments. It can withstand exposure to oils, solvents, acids, and other chemicals, ensuring long-lasting performance even in the most demanding applications.Another notable feature of this insulating sleeve is its exceptional flexibility. It can be easily installed on existing exhaust systems of various sizes and shapes, providing a customized and secure fit. The sleeve is designed to adapt to the contours of the hoses without compromising its insulation capabilities, allowing for easy integration and versatility across different industrial setups.Moreover, the unique design of this sleeve allows for efficient heat dissipation, preventing excessive temperature buildup within the exhaust system. This reduces the risk of thermal damage to surrounding components and ensures a safe working environment for operators.Beyond its technical advantages, the Exhaust Hose Insulation Sleeve also champions sustainability. Its high-performance insulation properties minimize heat loss, resulting in energy savings and reduced greenhouse gas emissions. By optimizing the thermal efficiency of industrial operations, it contributes to a greener and more environmentally conscious approach to manufacturing.The company behind this revolutionary product has a proven track record in delivering innovative engineered solutions for various industries. With a commitment to research and development, they continuously strive to push the boundaries of technology and engineering excellence. Through extensive testing and customer collaboration, they have successfully developed a product that meets the specific needs and demands of industrial applications.Furthermore, the company's dedicated team of experts offers unparalleled technical support, working closely with clients to ensure seamless integration of the Exhaust Hose Insulation Sleeve into their existing systems. Their expertise, combined with a customer-centric approach, guarantees a comprehensive solution that enhances productivity and operational efficiency.As industries increasingly prioritize efficiency, cost-effectiveness, and sustainability, the Exhaust Hose Insulation Sleeve emerges as a game-changer. Its exceptional thermal insulation, durability, chemical resistance, and flexibility make it a must-have solution for industrial operations across the globe. With its wide-ranging benefits and the expertise of the company behind it, this innovative product is set to make a lasting impact on the manufacturing landscape.

Essential Guide: Exploring Metal Wire Protector Sleeves for Enhanced Safety and Durability

[Company Name] Launches Innovative Metal Wire Protector Sleeve to Enhance Safety Measures[date][Location]In a bid to enhance safety measures and reduce hazards related to loose electrical wiring in homes and other settings, [Company Name] has introduced an innovative Metal Wire Protector Sleeve. This revolutionary product aims to provide users with a high level of protection against potential electrical accidents, thus ensuring a secure environment for both residential and commercial applications.The Metal Wire Protector Sleeve, designed by [Company Name], offers a durable and reliable solution to prevent the risks associated with exposed electrical wiring. With its advanced engineering and versatile design, this product acts as a protective shield over wires, shielding them from potential physical damage, corrosion, or insulation degradation caused by external factors.The primary function of the Metal Wire Protector Sleeve is to effectively eliminate the chances of accidental fires, electrical shocks, or short circuits that may stem from exposed wiring. Through its innovative construction, it significantly reduces the risk of electrical accidents by maintaining a physical barrier between the wiring and the surrounding environment.Furthermore, the Metal Wire Protector Sleeve is made from high-quality, flame-resistant materials that comply with industry standards. This ensures the product's longevity and the utmost safety for users. Additionally, the sleeve is designed to be easily installed, enabling users to seamlessly enhance the safety of their electrical systems without professional assistance."The safety and well-being of our customers has always been our top priority. With the introduction of the Metal Wire Protector Sleeve, we aim to provide them with a cost-effective and reliable solution to address the hazards associated with exposed electrical wiring," said [CEO/Founder] of [Company Name]. "We are confident that this innovative product will significantly reduce the risks of electrical accidents and contribute to creating safer living and working environments."The Metal Wire Protector Sleeve can be used in various applications, including homes, offices, factories, public spaces, and construction sites. Its adaptability allows it to safeguard wires in a diverse range of settings, making it an essential product in today's modern electrical installations.In addition to its safety features, the Metal Wire Protector Sleeve also offers a sleek and contemporary design that seamlessly blends with different architectural styles. Therefore, the product not only enhances the safety of electrical systems but also contributes to the overall aesthetics of the surrounding environment.The launch of the Metal Wire Protector Sleeve demonstrates [Company Name]'s commitment to constant innovation and its dedication to addressing the evolving safety needs of consumers. The introduction of this groundbreaking product serves as a testament to the company's emphasis on research and development, as well as its determination to provide reliable and effective solutions to its customers.To support the Metal Wire Protector Sleeve launch, [Company Name] is offering a limited-time promotional discount, enabling customers to obtain the product at an affordable price. This opportunity allows both individuals and businesses to invest in the safety of their electrical systems without breaking the bank.In conclusion, the introduction of [Company Name]'s Metal Wire Protector Sleeve marks a significant milestone in the field of electrical safety. With its advanced design, high-quality materials, easy installation, and sleek aesthetics, this product is poised to become an essential component of every electrical system. By prioritizing safety and delivering innovative solutions, [Company Name] continues to establish itself as a leader in the industry, ensuring the well-being of its customers and the safeguarding of electrical installations around the world.