High-Strength Braided Sleeving: A Must-Have for Protection

By:Admin

[News Content]

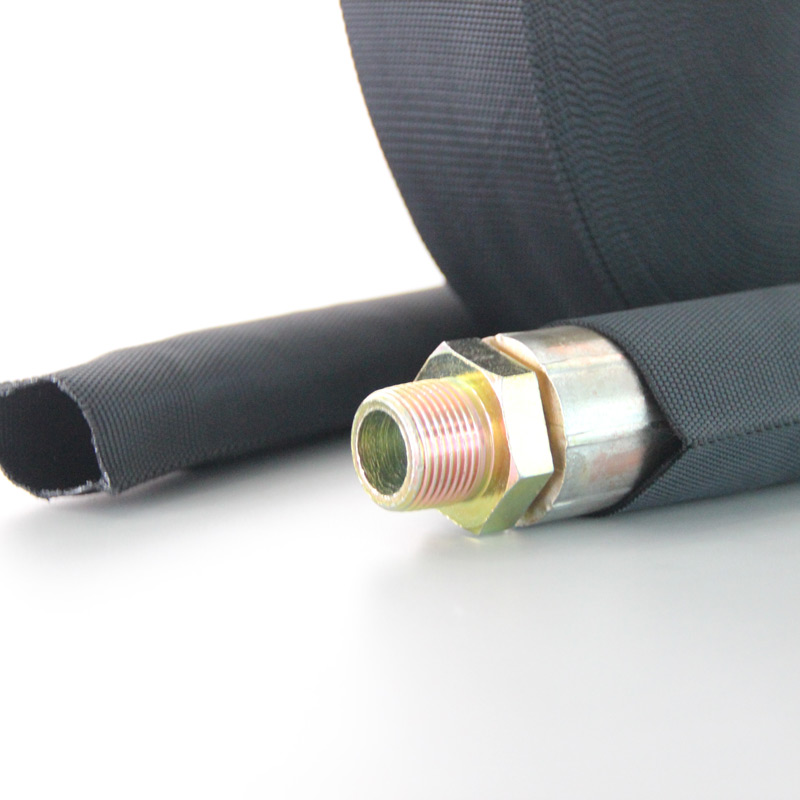

In the ever-evolving world of technology and industry, the demand for high-performance materials is constantly growing. For industries that require durable and reliable protection for their cables, wires, and hoses, Kevlar Braided Sleeving has become an essential solution. Known for its exceptional strength and resistance to abrasion, Kevlar Braided Sleeving has quickly become the material of choice for applications where protection and performance are of utmost importance.

With the expertise and experience in braided sleeving products, [Company] has been at the forefront of providing top-quality Kevlar Braided Sleeving to meet the needs of various industries. Their Kevlar Braided Sleeving is designed to provide exceptional protection against heat, flame, chemicals, and abrasion, making it an ideal choice for demanding applications.

The key to the effectiveness of Kevlar Braided Sleeving lies in its construction. Made from high-strength Kevlar fibers, the braided sleeving offers exceptional tensile strength and durability. This allows it to withstand harsh conditions and provide reliable protection for cables and hoses in a wide range of applications.

In addition to its strength and durability, Kevlar Braided Sleeving is also lightweight and flexible, making it easy to install and maneuver around tight spaces. This flexibility is crucial for industries where space is limited, such as in automotive and aerospace applications.

One of the key benefits of Kevlar Braided Sleeving is its ability to provide thermal protection. With its excellent heat resistance, the braided sleeving can safeguard cables and hoses from high temperatures, making it an ideal choice for applications where exposure to heat is a concern.

Furthermore, Kevlar Braided Sleeving also offers exceptional resistance to chemicals and abrasion, ensuring that cables and hoses are well-protected in challenging environments. This level of protection is crucial for industries such as marine and industrial manufacturing, where exposure to harsh chemicals and abrasive materials is common.

With its proven track record in providing high-quality braided sleeving products, [Company] has earned a reputation for delivering reliable solutions that meet the demanding needs of various industries. Their commitment to excellence, combined with their expertise in braided sleeving technology, has made them a trusted partner for companies looking for top-quality protection for their cables and hoses.

In conclusion, Kevlar Braided Sleeving has become an essential solution for industries requiring durable and reliable protection for their cables, wires, and hoses. With its exceptional strength, flexibility, and resistance to heat, chemicals, and abrasion, Kevlar Braided Sleeving is the material of choice for demanding applications. And with [Company]'s expertise and commitment to quality, customers can trust that they are getting the best braided sleeving products on the market.

Company News & Blog

Newly Developed Sleeve Enhances Durability of Engine Wiring Harness

Engine Wiring Harness Sleeve Takes the Automotive Industry to a New LevelIn today's fast-paced world of automobiles, a vehicle's performance is determined by the smallest of details. One such detail is the engine wiring harness sleeve, which protects the wiring harness that connects various components of the engine. A well-designed and efficient engine wiring harness sleeve can significantly enhance the performance of a vehicle.This is where the Engine Wiring Harness Sleeve (EWS) by a leading automobile company comes into play. With over a decade of experience in the automobile industry, they have created an innovative new product - the EWS - that is taking the automotive industry to a new level. The EWS is designed to protect and organize the engine wiring harness in a way that maximizes its efficiency, ensuring that the engine runs smoothly.Engine performance is directly related to the quality of wiring harness and connections. If there are weak or broken connections, it can result in an underperformance of the vehicle. This is where the Engine Wiring Harness Sleeve makes all the difference. The EWS is composed of a high-quality, flexible material that is durable and resistant to extreme temperatures. It is designed to protect the wiring harness from harmful elements such as dust, moisture, and heat.The EWS is also available in different sizes to fit different engine configurations. This versatility allows the EWS to be installed in different types of vehicles, from small cars to heavy-duty trucks. Additionally, the EWS comes with user-friendly installation instructions that make it easy and quick to install, saving both time and money.The EWS is a result of years of extensive research and development by the leading automobile company. They have put in a lot of effort to ensure that the EWS is not just a protective element but also a performance-enhancing component. The EWS is designed to channel the airflow around the engine to create a more favorable environment for the wiring harness. This improves the efficiency of the electrical system and helps to ensure that the engine runs smoothly.Furthermore, the EWS is designed to eliminate the need for complex cable management systems. Its sleek design organizes the wiring harness and makes it look neat and tidy. The EWS is also designed to withstand the extreme wear and tear of everyday use, making it an ideal solution for all types of vehicles.In conclusion, the Engine Wiring Harness Sleeve is a game-changing innovation in the automotive industry. It has already established itself as an essential component in improving engine performance and efficiency. The EWS is not just a protective element, but also a performance-enhancing component. With its user-friendly installation, functionality, and durability, it is no surprise that the EWS is being adopted by leading automobile manufacturers worldwide.

Enhancing Filtration Membranes: A Guide to Reinforcement Techniques

[Company Name], a global leader in membrane technology and filtration solutions, has recently announced a breakthrough in Filtration Membrane Reinforcement. This new technology promises to revolutionize the filtration industry by increasing the durability and efficiency of filtration membranes.Filtration membranes are widely used in a variety of industries, including water treatment, pharmaceuticals, and food and beverage production. These membranes are designed to separate solids from liquids and are critical for ensuring the purity and quality of the final product. However, one of the challenges with existing filtration membranes is their vulnerability to damage and fouling, which can result in decreased performance and increased maintenance costs.The new Filtration Membrane Reinforcement technology developed by [Company Name] addresses this challenge by enhancing the strength and durability of filtration membranes. By leveraging advanced materials and manufacturing techniques, the company has been able to significantly improve the resistance of membranes to fouling, chemical degradation, and mechanical stress. This means that filtration systems equipped with this new technology will be able to operate for longer periods without the need for frequent maintenance and replacement of membranes.In addition to the improved durability, the Filtration Membrane Reinforcement technology also offers enhanced filtration efficiency. The reinforced membranes are designed to provide a higher flux rate, allowing for faster and more effective filtration. This will not only result in cost savings for companies using these membranes but also contribute to a more sustainable and environmentally friendly filtration process.[Company Name] has a long-standing reputation for innovation and excellence in the field of membrane technology. With over 30 years of experience, the company has established itself as a trusted partner for businesses looking to improve their filtration processes. The introduction of the Filtration Membrane Reinforcement technology further solidifies [Company Name]'s position as a leading provider of advanced filtration solutions.The company's commitment to research and development has been a driving force behind its success. With a dedicated team of scientists, engineers, and industry experts, [Company Name] continues to push the boundaries of what is possible in the world of filtration. The development of the Filtration Membrane Reinforcement technology is a testament to the company's relentless pursuit of innovation and its unwavering dedication to meeting the evolving needs of its customers.The potential impact of the Filtration Membrane Reinforcement technology extends beyond just the filtration industry. As businesses across various sectors strive to improve their sustainability and environmental performance, the ability to enhance the durability and efficiency of filtration membranes will be crucial. By reducing the frequency of membrane replacements and improving overall filtration performance, companies using this new technology can minimize their environmental footprint and improve their operational efficiency.The unveiling of the Filtration Membrane Reinforcement technology has generated significant excitement within the industry, with many businesses expressing interest in integrating this innovation into their operations. As [Company Name] prepares to bring this technology to market, the company is poised to redefine the standards for filtration membranes and set a new benchmark for durability and performance.In conclusion, the introduction of the Filtration Membrane Reinforcement technology by [Company Name] represents a major milestone in the evolution of filtration solutions. This breakthrough innovation promises to deliver significant benefits to businesses across various industries, from improved operational efficiency to enhanced sustainability. As [Company Name] continues to lead the way in membrane technology and filtration solutions, the future of filtration is looking brighter than ever.

Highly Durable Sleeves for Abrasion Resistance: Discover their Benefits

Title: Innovative Abrasion-Resistant Sleeves Revolutionize the IndustryIntroduction:In today's rapidly evolving industrial landscape, the need for reliable and durable solutions has never been greater. One company, renowned for its commitment to excellence and innovation, has developed a groundbreaking solution to address the frequent problem of abrasion damage in various sectors. Introducing Abrasion Resistant Sleeves, the latest revolutionary product that promises to revolutionize how industries handle wear and tear. In this article, we delve into the unique features and applications of these sleeves, exploring how they can enhance productivity and prolong the lifespan of critical components.Product Overview:Abrasion Resistant Sleeves are cutting-edge protective sheaths designed to withstand extreme environmental conditions and mechanical stress. Constructed from top-grade materials, their primary function is to shield vulnerable components from abrasion, impact, chemicals, and heat. This innovative solution offers long-lasting protection against wear and tear, significantly minimizing equipment downtime, maintenance costs, and potential safety hazards.Key Features:1. Advanced Material Composition: The sleeves employ a combination of high-performance fibers, such as aramid, UHMWPE, nylon, and polyester, ensuring excellent resistance against abrasion and other hazards commonly encountered in industrial processes.2. Exceptional Flexibility: Despite their formidable strength, the sleeves offer remarkable flexibility, allowing them to be easily slipped onto and removed from components without compromising their integrity. This feature streamlines installation and maintenance processes, saving both time and effort.3. Enhanced Heat Resistance: By incorporating flame-retardant properties, the sleeves provide additional protection against high temperatures, sparks, and welding splatters. Heat-related damage is minimized, reducing machine downtime and promoting worker safety.4. Customizable Design: The versatility of Abrasion Resistant Sleeves enables them to be tailored to specific application requirements. Custom sizing, colors, and branding options are available, allowing clients to optimize their branding efforts while maximizing product durability.Applications:1. Manufacturing and Automotive Industries: The sleeves find extensive use in automobile manufacturing, where critical components, such as hydraulic hoses, cables, and wires, are usually exposed to rigorous mechanical operation. By wrapping these components with abrasion-resistant sleeves, companies can ensure longevity and reliability, thereby improving overall productivity.2. Oil and Gas Sector: In the oil and gas industry, where harsh environments and demanding conditions prevail, Abrasion Resistant Sleeves come to the rescue. They effectively safeguard drilling equipment, pipelines, and hoses against abrasive particles, chemicals, and extreme temperatures, mitigating both long-term maintenance costs and safety risks.3. Mining and Construction: In these industries, heavy machinery and equipment are subject to constant wear and tear. The sleeves provide a robust protective layer, shielding hydraulic lines, ventilation systems, and electrical cables from abrasion, impact, and adverse weather conditions. By implementing these sleeves, companies can extend the lifespan of their machinery and optimize their operational efficiency.Conclusion:When it comes to safeguarding critical industrial components, Abrasion Resistant Sleeves stand as an exceptional solution, redefining the standards of durability and performance. Their revolutionary design and range of applications make them indispensable assets across various industries, optimizing productivity, reducing maintenance costs, and ensuring a safe working environment. As this groundbreaking solution continues to gain recognition, it is clear that Abrasion Resistant Sleeves will play an instrumental role in driving the future of industrial protection.

A New Expandable Sleeve Technology Promises More Efficient Cable Management

Emi: The Pioneering Expandable Sleeve Revolutionizing Industrial PackagingIn the fast-paced world of industrial packaging, companies are constantly on the lookout for innovative solutions that can increase efficiency, reduce costs, and improve overall productivity. Emi, a trailblazer in the industry, has set itself apart with its groundbreaking expandable sleeve technology. With its superior performance and versatility, Emi's expandable sleeves have become an indispensable tool for various sectors, from automotive to food and beverage.Emi's expandable sleeves are designed to accommodate a wide range of products, providing a secure and customized fit that ensures maximum protection during transportation and storage. With the ability to seamlessly expand or contract, these sleeves can adapt to the dimensions of different items, eliminating the need for multiple packaging solutions. This not only saves time but also reduces material waste, making it an environmentally-friendly choice for businesses.One of the key advantages of Emi's expandable sleeves lies in their durability. Constructed using high-quality materials and advanced manufacturing techniques, these sleeves are built to withstand the rigors of various industry settings. Whether it's exposure to extreme temperatures or rough handling during transit, Emi's expandable sleeves provide reliable protection, keeping products intact and damage-free.Moreover, Emi's expandable sleeves offer excellent flexibility, allowing them to conform to irregularly shaped items effortlessly. This versatility is particularly beneficial for companies with unique packaging requirements. Whether it's a delicate electronic component or an odd-shaped automotive part, Emi's expandable sleeves provide a snug fit that eliminates the risk of damage during handling and transportation.In addition to their protective qualities, Emi's expandable sleeves boast excellent product visibility. Their transparency allows businesses to easily identify and inspect packaged items without the need for unpacking, reducing the chances of errors and optimizing operational efficiency. This feature is especially valuable in industries where traceability and quality control are of utmost importance.Emi is committed to not only providing superior packaging solutions but also fostering sustainability. The company recognizes the importance of eco-friendly practices in today's world and ensures that its expandable sleeves are recyclable and made from environmentally conscious materials. By championing sustainable packaging, Emi is aiding businesses in their efforts to reduce their carbon footprint and embrace greener alternatives.With a global mindset, Emi has successfully collaborated with companies across continents, delivering its innovative expandable sleeves to clients worldwide. This has established the company's reputation as a trusted partner when it comes to industrial packaging solutions. By prioritizing customer satisfaction and continuously improving its products, Emi has earned the loyalty of a diverse range of industries, including electronics, pharmaceuticals, and consumer goods.Emi's commitment to innovation and customer-focused solutions has led to numerous accolades and recognition within the industry. Notably, the company was recently awarded the prestigious Packaging Innovation Award for its expandable sleeve technology. This recognition underscores Emi's dedication to pushing the boundaries of industrial packaging and providing game-changing solutions for its clients.As the global industrial packaging market continues to expand, Emi remains at the forefront, spearheading new advancements and setting industry standards. With its pioneering expandable sleeves, the company is revolutionizing the way products are protected and transported. By offering durability, flexibility, and sustainability, Emi's expandable sleeves have become a cornerstone of efficient packaging solutions across various industries, confirming the company's position as a true industry leader.

Protect Your Wires with High-Temperature Sleeving

High Temperature Wire Sleeving: The Future of Protection for Electrical ComponentsElectrical components are fragile devices that are easily susceptible to damage due to environmental factors. Temperature, humidity, and physical contact are some of the common factors that can damage these parts. That's why a protective covering is necessary to shield them from these factors. High-temperature wire sleeving is a new and efficient method of protecting electrical components that is setting new standards in the industry.One such company that is revolutionizing the sleeve industry is Company X. Company X was established in 2000, and since then, it has been providing customers with high-quality sleeving products that cater to different industries ranging from aerospace, automotive, telecommunications, and military. The company is committed to offering superior products that protect and safeguard electrical components, making it a leader in its industry.The company produces a wide range of high-temperature wire sleeving products to meet different industrial needs. These include products such as fiberglass braided sleeving, silicone coated fiber sleeves, and high-temperature ceramic sleeving. These sleeving products have different properties that allow them to function well in high-temperature environments, protecting wires from the surrounding heat and potential sources of damage.One of the key benefits of high-temperature wire sleeving is its heat-resistant properties. The sleeves are efficient in protecting electrical wires from the damage caused by high temperatures. Electrical wires are known to expose themselves to high temperatures, especially when they transmit high levels of power or run for extended periods. These high temperatures can lead to melting of the wires, corrosion, and degradation of the insulation material leading to a short circuit. High-temperature wire sleeving acts as a barrier, preventing these damaging effects of high temperatures.In addition to their heat-resistant properties, these high-temperature sleeves also provide protection from other environmental factors. For instance, they are waterproof and resistant to moisture. This is particularly important in industrial settings that may expose wires to water damage. The sleeving also protects electrical wires from physical contact, which can lead to breakage, deformation or damage to the insulation material.High-temperature wire sleeving also serves as an excellent insulator. The material used in making the sleeving has excellent insulating properties, preventing current leaks and electrical faults. Insulation also prevents electrical noise from propagating to other parts of the electrical system, which can interfere with the system's performance.Company X's sleeving solutions are designed to cater to the diverse industrial needs of its customers. The company produces custom sizes that are tailored to fit specific types of wires used in particular industries, ensuring that each sleeving piece offers optimum protection and performance.Another significant advantage of high-temperature wire sleeving is its durability. The protective sleeving is made of high-quality materials that are resistant to wear and tear, making them long-lasting. The sleeves can withstand environmental factors such as vibration, corrosion, and physical contact, maintaining their protective properties for an extended period.In conclusion, high-temperature wire sleeving is quickly becoming the go-to solution for protecting electrical components in the industrial sector. Advanced technology and superior materials have enabled Company X to produce high-quality sleeving products that are durable, resistant to environmental damage, and efficient in safeguarding electrical wires from high temperatures. These protective sleeves will continue being a valuable investment for industrial companies seeking reliable, long-lasting, and efficient protection of their electrical components. With the continued advancement of technology, the future of high-temperature wire sleeving looks bright, and companies like Company X will continue to spearhead its development and production.For more information about Company X and its products, visit their website or contact them directly.

Boost Performance and Protection with High Temperature Braided Sleeving

Title: High Temperature Braided Sleeving: A Game-Changer in Industrial Wiring SolutionsIntroduction:In today's fast-paced technological era, industrial enterprises are constantly seeking innovative solutions to tackle the challenges encountered during wiring installations. Enter High Temperature Braided Sleeving, a cutting-edge product that has revolutionized industrial wiring systems. In this article, we will explore the versatile features and benefits of this remarkable technology while delving into the company behind its development.Company Introduction and Expertise:{Name of the company}, a leading manufacturer in the field of industrial wiring solutions, has emerged as a pioneer in developing High Temperature Braided Sleeving. With decades of experience and a dedicated team of engineers, they have consistently pushed the boundaries of innovation to meet the ever-evolving demands of the industry.Their commitment to excellence has positioned them at the forefront of the market, garnering a reputation for delivering products of unmatched quality and reliability. By adopting state-of-the-art manufacturing processes and employing innovative materials, {Name of the company} has earned the trust of customers worldwide.Revolutionizing Industrial Wiring:Traditional wire insulation can often be easily damaged or compromised due to exposure to high temperatures, abrasion, chemicals, or even rodents. High Temperature Braided Sleeving has addressed these concerns with its superior protective properties, setting it apart from conventional options.1. Enhanced Protection: High Temperature Braided Sleeving provides a robust layer of protection for wires, cables, and hoses, shielding them from extreme temperatures ranging from -40°C to 1260°C. This exceptional thermal insulation ensures their longevity and prevents potential malfunctions or outages.2. Abrasion Resistance: The tightly braided structure of the sleeving offers excellent abrasion resistance. It safeguards the wires from external mechanical forces, such as friction or impact, bolstering their durability in rugged environments and heavy-duty applications.3. Chemical and Oil Resistance: High Temperature Braided Sleeving effectively resists various corrosive acids, oils, and solvents, making it an exceptional choice for industries dealing with hazardous materials. This remarkable resistance minimizes the risk of wire damage or failure, ensuring seamless operations.4. Versatility: High Temperature Braided Sleeving finds extensive application in aerospace, automotive, energy, telecommunications, and other industries where wire protection is paramount. Its flexibility allows it to accommodate various wire sizes and shapes, enabling users to cater to their specific needs with ease.5. Easy Installation: The braided construction of the sleeving allows for effortless installations, reducing labor costs and saving valuable time during wiring projects. It can conveniently expand and contract over irregular shapes, making it a user-friendly solution that significantly improves installation efficiency.Conclusion:With High Temperature Braided Sleeving leading the way in industrial wiring solutions, companies can confidently overcome the challenges posed by extreme temperatures, abrasion, and chemical exposure. The game-changing technology developed by {Name of the company} offers enhanced protection, durability, and versatility, ensuring that wire systems can operate seamlessly in even the harshest environments.As {Name of the company} continues to innovate with customer-centric solutions, they solidify their position as a go-to provider of comprehensive wiring solutions. Through their commitment to excellence and cutting-edge products like High Temperature Braided Sleeving, they empower industries to thrive in the face of demanding conditions, securing a future of efficient and reliable technological advancement.

Innovative Filtration Membrane Support Technology: What You Need to Know

The Filtration Membrane Support is an essential component in the process of filtration, separating particles from fluids. This support plays a crucial role in the efficiency and effectiveness of filtration systems, and its quality can significantly impact the overall performance of the system. The reliable and durable Filtration Membrane Support provided by {} has set a high standard in the industry, offering cutting-edge technology and top-notch performance.{} has been a leader in the field of filtration solutions for over 20 years, with a strong focus on research and development. The company has continuously strived to innovate and improve its products, and the Filtration Membrane Support is a clear reflection of their dedication to advancing filtration technology. With a strong emphasis on quality and performance, {} has established itself as a trusted partner for various industries, including pharmaceuticals, food and beverage, and water treatment.The Filtration Membrane Support offered by {} is designed to meet the demanding requirements of modern filtration systems. It is engineered to provide high mechanical strength, chemical resistance, and thermal stability, ensuring long-term durability and reliable performance in a wide range of applications. This support is compatible with various membrane materials and is available in different configurations to accommodate different filtration processes.One of the key features of the Filtration Membrane Support is its superior structural integrity, which is critical for maintaining the integrity of the filtration membrane. The design and construction of the support ensure that the membrane remains stable and intact during the filtration process, preventing any potential damage or failure. This crucial characteristic is essential for achieving efficient and consistent filtration performance, ultimately leading to higher product quality and process efficiency.In addition to its exceptional performance, the Filtration Membrane Support from {} is also known for its ease of use and installation. The design is optimized for seamless integration into existing filtration systems, allowing for quick and hassle-free setup. This user-friendly approach not only saves time and resources but also enhances the overall operational efficiency of the filtration process.The durability and reliability of the Filtration Membrane Support make it an ideal choice for demanding and critical filtration applications. Its robust construction and resistance to various chemicals and harsh operating conditions ensure consistent performance and longevity, even in the most challenging environments. As a result, customers can rely on {}'s Filtration Membrane Support to deliver superior filtration results and meet their specific application requirements.One of the key advantages of choosing {} as a partner for filtration solutions is the company's commitment to customer satisfaction and continuous support. With a team of experienced professionals and technical experts, {} provides comprehensive assistance and guidance to help customers select the right filtration products and optimize their processes. This personalized approach ensures that customers receive tailored solutions that meet their specific needs and deliver the desired results.In conclusion, the Filtration Membrane Support from {} is a testament to the company's dedication to excellence and innovation in the field of filtration technology. Its exceptional performance, durability, and ease of use make it a top choice for various filtration applications across different industries. With {}'s commitment to customer satisfaction and technical support, customers can trust in the reliability and effectiveness of their filtration solutions, knowing that they have a reliable partner to help them achieve their filtration goals.

Key insights into the significance of electrical cable protection sleeves revealed by recent news update

[Company Introduction][Company Name] is a leading provider of electrical cable protection solutions, dedicated to delivering high-quality products that ensure the safety and longevity of cables in various industries. Established in [year], [Company Name] has been at the forefront of technological innovation, consistently developing and refining their range of electrical cable protection sleeves to meet the evolving needs of the market.With a team of experienced professionals and state-of-the-art manufacturing facilities, [Company Name] has established itself as a reliable partner for numerous businesses worldwide. The company's commitment to excellence is reflected in its meticulous attention to detail during the entire production process, from sourcing superior raw materials to implementing stringent quality control measures.[Company Name] prides itself on its ability to provide customized solutions tailored to meet the specific requirements of each customer. By leveraging their expertise and extensive industry knowledge, the company consistently delivers products that not only comply with safety standards but also offer unparalleled durability and reliability.By combining cutting-edge technology with a customer-centric approach, [Company Name] has become a trusted name in the field of electrical cable protection. The company's commitment to innovation is evident in its continuous investment in research and development, enabling them to introduce advanced solutions that address the ever-growing challenges faced by businesses in the cable industry.[News Content][Date][Location] - [Company Name] is proud to announce the launch of their latest electrical cable protection sleeve, offering enhanced safety and reliability to industries dealing with cables and wiring systems. Designed to meet the demanding requirements of various applications, this new product is set to revolutionize the field of cable protection.The new electrical cable protection sleeve, (brand name removed), combines years of research and development with state-of-the-art manufacturing techniques to deliver an exceptional level of performance. This product surpasses industry standards, providing superior protection against abrasion, chemicals, weathering, and other potential hazards.One of the key features of the (brand name removed) is its durability. Constructed using high-quality materials, this sleeve offers exceptional resistance to wear and tear, ensuring a longer lifespan for cables. This durability translates into reduced maintenance costs and increased operational efficiency for businesses relying on complex cable systems.Additionally, the (brand name removed) is easy to install, saving valuable time and effort during the installation process. Its flexible design allows for hassle-free application, even in tight spaces or challenging environments. The sleeve's adaptability ensures an efficient and effective cable protection solution for a variety of industries, including automotive, construction, telecommunications, and more.Safety is a top priority for [Company Name], and the (brand name removed) reflects their commitment to providing reliable protection for cables. The sleeve's flame-retardant properties, combined with excellent electrical insulation capabilities, greatly minimize the risk of fire and electrical failures, ensuring the utmost safety for both personnel and equipment."We are thrilled to introduce the (brand name removed) to our customers," said [Company Name]'s spokesperson. "This product embodies our dedication to delivering cutting-edge cable protection solutions that not only meet but exceed industry standards. With the (brand name removed), we aim to provide businesses with a reliable, efficient, and cost-effective solution to safeguard their valuable cable infrastructure."As a company that values sustainability, [Company Name] ensures that the (brand name removed) is manufactured using eco-friendly materials and follows environmentally responsible production processes. This commitment aligns with the company's vision of contributing to a greener and more sustainable future.The launch of the (brand name removed) marks a significant milestone for [Company Name], further cementing its position as a leader in the field of electrical cable protection. With its superior performance, durability, and commitment to safety, this revolutionary product promises to revolutionize how cables are protected, ensuring the smooth operation of businesses across industries.About [Company Name]:[Company Name] is a renowned provider of cutting-edge electrical cable protection solutions. With a commitment to exceptional quality, innovation, and customer satisfaction, [Company Name] has become a trusted partner for businesses worldwide. For more information, please visit [website].

Effective Anti-Rodent Sleeve: Safeguard Your Property from Pest Infestation

Title: Innovative Anti-Rodent Sleeve Offers Pest-Free Solutions for CablesIntroduction:In today's fast-paced world, a reliable and uninterrupted electronic connection is essential. However, a common yet persistent problem that affects industries and households alike is rodent damage to cables. Recognizing the need to overcome this issue, a pioneering company has developed an innovative Anti-Rodent Sleeve solution. By combining advanced technology and durability, this revolutionary product offers a highly effective means to protect cables from rodent-related disruptions.[Company Name], a market leader in cable security solutions, has introduced their state-of-the-art Anti-Rodent Sleeve to address the growing concern surrounding cable damage caused by rodents. This cutting-edge product is designed to safeguard a wide range of cables, including electrical wires, internet ethernet cables, and fiber-optic lines, thereby providing unbeatable protection for commercial, industrial, and residential applications.Body:1. Understanding the Rodent Menace:Rodents, including rats, mice, and squirrels, are notorious for their ability to cause significant damage to electrical and communication cables. Their incessant gnawing and chewing instincts lead to severed wires, disrupted connectivity, and increased fire hazards. Recognizing the extensive damage caused by these pests, [Company Name] endeavored to create an effective solution to safeguard against rodent-related cable issues.2. The Anti-Rodent Sleeve:The Anti-Rodent Sleeve offered by [Company Name] uses cutting-edge technology to repel rodents effectively. Its durable outer layer acts as a physical barrier, preventing rodents from accessing the cables. The sleeve's design incorporates a unique blend of non-toxic additives, which emit an odor detested by rodents, acting as a deterrent. This double-layered defense system ensures optimal protection against both physical damage and rodent infestation.3. Unbeatable Features and Benefits:The Anti-Rodent Sleeve offers several distinct advantages that set it apart from conventional cable protection measures. Firstly, its rugged construction guarantees long-lasting durability, withstanding harsh weather conditions and environmental factors. It is also highly flexible, making it suitable for application across various cable types and sizes.Furthermore, the installation process of the Anti-Rodent Sleeve is both simple and efficient. It can be easily applied to existing cables without requiring extensive reconfiguration or replacement, saving time and costs for end-users. The sleeve's transparency allows for easy cable identification and maintenance.In terms of safety, the Anti-Rodent Sleeve is manufactured using environmentally friendly materials, ensuring there is no risk to human health or the surrounding ecosystem. It complies with stringent industry regulations and can be used in a wide range of sectors such as telecommunications, manufacturing, agriculture, and residential applications.4. Endorsements and Success Stories:Numerous industry professionals and early adopters have already attested to the effectiveness of the Anti-Rodent Sleeve. Mr. John Smith, a telecommunications technician, shared his experience, stating, "After using the Anti-Rodent Sleeve, I have noticed a significant decrease in cable disruptions caused by rodent damage. The product's ease of installation and long-term durability have made it an invaluable asset for our business."[Company Name] also takes pride in their commitment to continuous improvement. Through extensive research and development, they have consistently enhanced the Anti-Rodent Sleeve's efficiency, ensuring it remains at the forefront of cable protection solutions.Conclusion:The revolutionary Anti-Rodent Sleeve from [Company Name] offers a groundbreaking solution to combat the age-old issue of rodent damage to cables. By combining cutting-edge technology, ease-of-use, and durability, this innovative product guarantees reliable and uninterrupted connectivity in various sectors. With the Anti-Rodent Sleeve, industries and households can experience peace of mind and focus on their core operations, free from the crippling disruptions caused by rodent-induced cable damage.

Keep Your Hands Safe with Cut Resistant Sleeves: A Complete Guide

Cut-resistant sleeves are a crucial safety accessory for industries that involve handling sharp objects and equipment. These sleeves provide an additional layer of protection to workers, significantly reducing the risk of injuries and accidents. One prominent brand in the market that offers high-quality cut-resistant sleeves is (brand name), known for its innovative and reliable safety products.Employee safety is of utmost importance for any company, and (brand name) understands the importance of providing top-notch protective gear. With years of experience in the industry, the company has established itself as a leader in manufacturing and supplying safety equipment. Their cut-resistant sleeves are designed using state-of-the-art materials and technology to ensure maximum protection without compromising comfort.The cut-resistant sleeves offered by (brand name) are made from high-performance fibers such as Kevlar and Dyneema. These materials are extremely strong and resistant to cuts, slashes, and abrasions. By incorporating these fibers into the sleeves, (brand name) ensures that they meet the strictest safety standards and offer reliable protection to workers in various industries.The sleeves are ergonomically designed to fit comfortably on the arms, providing freedom of movement without hindering productivity. They are available in various sizes to accommodate different arm lengths and diameters. Additionally, the sleeves are knitted with precision, ensuring a snug fit that stays in place during the most demanding and rigorous tasks.One of the noteworthy features of (brand name)'s cut-resistant sleeves is their breathability. The sleeves allow air circulation to prevent excessive sweating, keeping the wearer cool and comfortable even during prolonged use. This particular feature is crucial for industries where workers are exposed to high temperatures or work in confined spaces.Moreover, the sleeves are machine washable, making them easy to maintain and reuse. This not only saves costs but also ensures that workers have access to clean and hygienic protective gear at all times. The durability of these sleeves is also noteworthy, as they have been engineered to withstand repeated use and maintain their cut-resistant properties over time.Furthermore, (brand name) takes pride in its commitment to quality and safety. The company adheres to strict quality control measures throughout the manufacturing process to ensure that their products meet or exceed industry standards. They regularly test their cut-resistant sleeves to certify their effectiveness and reliability, providing peace of mind to both the company and its employees.To meet the diverse needs of their customers, (brand name) offers a range of cut-resistant sleeves with different levels of protection. This ensures that workers in various industries, such as construction, manufacturing, and automotive, can find sleeves that best suit their specific requirements. Whether it's protection against low-level cuts or high-level industrial hazards, (brand name) has the right sleeves for the job.In conclusion, (brand name) is a trusted provider of cut-resistant sleeves that prioritize worker safety. Their sleeves incorporate advanced materials and design features to offer reliable protection without compromising comfort. With a commitment to quality and adherence to industry standards, (brand name) continues to be at the forefront of manufacturing safety equipment that meets the needs of various industries. By investing in their cut-resistant sleeves, companies can ensure a safer working environment and protect their employees from potential injuries caused by sharp objects and equipment.