How Sleeving Technology is Revolutionizing the Packaging Industry

By:Admin

In an era where technology is advancing at an unprecedented pace, the need for effective electromagnetic interference (EMI) shielding has become increasingly important. As electronic devices continue to evolve and become more complex, the risk of EMI interference has grown, potentially leading to damage or malfunction of vital components. In response to this growing demand, [Company Name], a leading tech company, has developed Emi Sleeving, a revolutionary solution that provides superior EMI shielding for a wide range of applications.

Emi Sleeving is a high-performance, flexible shielding solution that can be easily installed on cables, wires, and other electronic components to protect them from the harmful effects of EMI. This innovative product is designed to meet the stringent demands of today’s electronic devices, providing reliable and consistent protection against electromagnetic interference.

One of the key features of Emi Sleeving is its versatility. Available in a variety of sizes, materials, and configurations, Emi Sleeving can be customized to meet the specific needs of different applications, ensuring that it provides optimal EMI shielding for a wide range of electronic devices. Whether it’s used in aerospace, automotive, medical, or consumer electronics industries, Emi Sleeving offers a flexible and effective solution for EMI shielding.

Furthermore, Emi Sleeving is also designed to meet the highest quality and safety standards. Manufactured using advanced materials and production techniques, Emi Sleeving is engineered to provide long-lasting and reliable EMI protection, ensuring that electronic devices perform at their best without the risk of interference.

In addition to its superior performance, Emi Sleeving also offers ease of installation. With its flexible and durable construction, Emi Sleeving can be easily applied to cables and wires, providing a seamless and efficient solution for EMI shielding. This makes it an ideal choice for manufacturers and engineers looking for a reliable and convenient solution to protect their electronic devices from EMI interference.

[Company Name] is committed to providing cutting-edge solutions that meet the evolving needs of the tech industry. With Emi Sleeving, the company has demonstrated its dedication to innovation and excellence, offering a game-changing solution that addresses the pressing need for effective EMI shielding in today’s electronic devices.

As a leader in the tech industry, [Company Name] is well-positioned to bring Emi Sleeving to market, leveraging its extensive expertise and resources to ensure that this revolutionary product meets the highest standards of quality and performance. With Emi Sleeving, [Company Name] is setting a new standard for EMI shielding, providing a solution that is both reliable and efficient for a wide range of electronic applications.

In conclusion, Emi Sleeving by [Company Name] represents a significant advancement in EMI shielding technology, offering a flexible, high-performance, and reliable solution for protecting electronic devices from the harmful effects of electromagnetic interference. As electronic devices continue to evolve and become more prevalent in our daily lives, the need for effective EMI shielding has never been greater. With Emi Sleeving, [Company Name] has demonstrated its commitment to addressing this critical need, providing a solution that is poised to make a lasting impact in the tech industry.

Company News & Blog

High-quality Engine Wiring Harness Sleeve for Efficient Performance

[Company Introduction: The company is a leading manufacturer of automotive components, specializing in the production of wiring harness sleeves for various vehicles. With a strong focus on innovation and quality, the company has established a reputation for producing high-performance products that meet industry standards and customer expectations. The company's dedication to research and development has led to the creation of cutting-edge solutions that are used by leading automotive manufacturers across the globe.]The company is pleased to announce the launch of its latest innovation, the Engine Wiring Harness Sleeve. Designed to meet the evolving needs of the automotive industry, this new product is set to revolutionize the way wiring harnesses are used in vehicles.The Engine Wiring Harness Sleeve is engineered to provide superior protection for the delicate wiring components within the engine compartment. With its durable and heat-resistant material, the sleeve acts as a barrier against potential damage from heat, vibrations, and other environmental factors. This not only extends the lifespan of the wiring harness but also ensures the smooth and uninterrupted performance of the engine.In addition to its protective capabilities, the Engine Wiring Harness Sleeve is also designed for easy installation and maintenance. Its flexible and lightweight construction allows for seamless integration into the existing wiring system, eliminating the need for extensive modifications or specialized tools. This not only saves time and resources for the manufacturer but also enhances the overall efficiency of the assembly process.Furthermore, the Engine Wiring Harness Sleeve is available in a variety of sizes and configurations to accommodate different engine layouts and specifications. This flexibility enables automotive manufacturers to meet specific design requirements without compromising on the performance and safety of the wiring harness.The launch of the Engine Wiring Harness Sleeve further solidifies the company's commitment to delivering innovative solutions that address the evolving needs of the automotive industry. With its advanced technology and unmatched quality, this new product is set to set a new standard for engine wiring protection and performance.In line with the company's dedication to sustainability, the Engine Wiring Harness Sleeve is also developed with eco-friendly materials that meet industry regulations and standards. This ensures that the product not only benefits the automotive industry but also contributes to the larger goal of reducing environmental impact.As a leading manufacturer of automotive components, the company is committed to supporting its customers with comprehensive technical support and resources. In addition to the Engine Wiring Harness Sleeve, the company offers a range of complementary products and services that are designed to enhance the overall performance and reliability of vehicle wiring systems.In conclusion, the launch of the Engine Wiring Harness Sleeve represents a significant milestone for the company and the automotive industry as a whole. With its advanced technology, superior protection, and environmental sustainability, this new product is poised to make a lasting impact on vehicle design and performance.The company looks forward to collaborating with automotive manufacturers and industry partners to integrate the Engine Wiring Harness Sleeve into their future vehicle models. As the automotive industry continues to evolve, the company remains committed to innovating and delivering solutions that elevate the standards of vehicle performance and safety.

Essential Guide: Exploring Metal Wire Protector Sleeves for Enhanced Safety and Durability

[Company Name] Launches Innovative Metal Wire Protector Sleeve to Enhance Safety Measures[date][Location]In a bid to enhance safety measures and reduce hazards related to loose electrical wiring in homes and other settings, [Company Name] has introduced an innovative Metal Wire Protector Sleeve. This revolutionary product aims to provide users with a high level of protection against potential electrical accidents, thus ensuring a secure environment for both residential and commercial applications.The Metal Wire Protector Sleeve, designed by [Company Name], offers a durable and reliable solution to prevent the risks associated with exposed electrical wiring. With its advanced engineering and versatile design, this product acts as a protective shield over wires, shielding them from potential physical damage, corrosion, or insulation degradation caused by external factors.The primary function of the Metal Wire Protector Sleeve is to effectively eliminate the chances of accidental fires, electrical shocks, or short circuits that may stem from exposed wiring. Through its innovative construction, it significantly reduces the risk of electrical accidents by maintaining a physical barrier between the wiring and the surrounding environment.Furthermore, the Metal Wire Protector Sleeve is made from high-quality, flame-resistant materials that comply with industry standards. This ensures the product's longevity and the utmost safety for users. Additionally, the sleeve is designed to be easily installed, enabling users to seamlessly enhance the safety of their electrical systems without professional assistance."The safety and well-being of our customers has always been our top priority. With the introduction of the Metal Wire Protector Sleeve, we aim to provide them with a cost-effective and reliable solution to address the hazards associated with exposed electrical wiring," said [CEO/Founder] of [Company Name]. "We are confident that this innovative product will significantly reduce the risks of electrical accidents and contribute to creating safer living and working environments."The Metal Wire Protector Sleeve can be used in various applications, including homes, offices, factories, public spaces, and construction sites. Its adaptability allows it to safeguard wires in a diverse range of settings, making it an essential product in today's modern electrical installations.In addition to its safety features, the Metal Wire Protector Sleeve also offers a sleek and contemporary design that seamlessly blends with different architectural styles. Therefore, the product not only enhances the safety of electrical systems but also contributes to the overall aesthetics of the surrounding environment.The launch of the Metal Wire Protector Sleeve demonstrates [Company Name]'s commitment to constant innovation and its dedication to addressing the evolving safety needs of consumers. The introduction of this groundbreaking product serves as a testament to the company's emphasis on research and development, as well as its determination to provide reliable and effective solutions to its customers.To support the Metal Wire Protector Sleeve launch, [Company Name] is offering a limited-time promotional discount, enabling customers to obtain the product at an affordable price. This opportunity allows both individuals and businesses to invest in the safety of their electrical systems without breaking the bank.In conclusion, the introduction of [Company Name]'s Metal Wire Protector Sleeve marks a significant milestone in the field of electrical safety. With its advanced design, high-quality materials, easy installation, and sleek aesthetics, this product is poised to become an essential component of every electrical system. By prioritizing safety and delivering innovative solutions, [Company Name] continues to establish itself as a leader in the industry, ensuring the well-being of its customers and the safeguarding of electrical installations around the world.

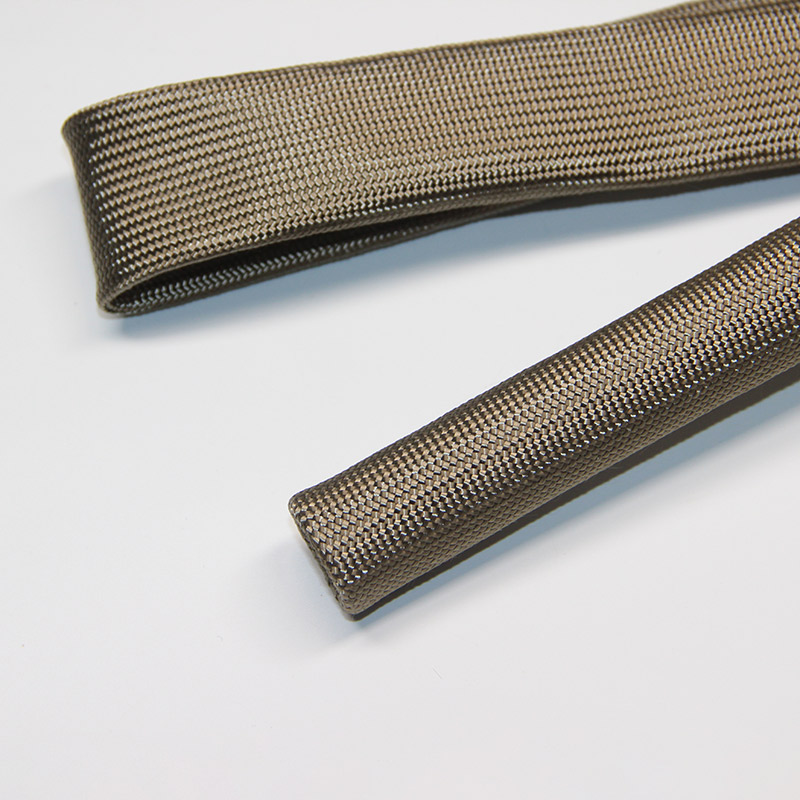

Durable and Flexible Braided Tube Sleeve for Various Applications

Braided Tube Sleeve Provides Durability and Protection for Industrial Applications{Company Name}, a leading provider of industrial solutions, is proud to offer their high-quality Braided Tube Sleeve to provide durability and protection for a wide range of industrial applications. This innovative product is designed to withstand harsh environments and provide long-lasting performance, making it an ideal choice for businesses looking to enhance the reliability of their equipment.The Braided Tube Sleeve is made from high-strength materials to provide maximum abrasion and wear resistance, making it suitable for use in demanding industrial settings. It is designed to wrap around hoses, cables, and wires to provide an extra layer of protection against mechanical damage, while also offering thermal insulation and resistance to chemicals and fluids.One of the key benefits of the Braided Tube Sleeve is its flexibility, which allows it to accommodate bends and twists without compromising its protective properties. This makes it an excellent choice for applications where hoses and cables are subject to frequent movement or vibration. Additionally, the sleeve is available in a range of sizes and configurations to suit different requirements, ensuring that businesses can find the perfect solution for their specific needs.The Braided Tube Sleeve is easy to install and can be quickly and securely fastened using standard tools, making it a convenient choice for businesses looking to improve the performance of their equipment without extensive downtime. Its lightweight and compact design also means that it adds minimal bulk to hoses and cables, allowing for easier handling and storage.In addition to its protective qualities, the Braided Tube Sleeve also offers a professional and clean appearance, which can help to improve the overall aesthetics of industrial equipment. This can be particularly important for businesses that have customer-facing operations or are looking to maintain high standards of cleanliness and organization in their facilities.{Company Name} is committed to providing superior products and services to meet the diverse needs of industrial businesses, and the Braided Tube Sleeve is a testament to this dedication. With its exceptional durability, versatility, and ease of use, this product is an excellent choice for businesses looking to enhance the reliability and performance of their equipment.The company’s team of experts is available to provide guidance and support to businesses looking to integrate the Braided Tube Sleeve into their operations. Their extensive knowledge and experience in industrial solutions enable them to understand the unique requirements of each customer and recommend the most suitable products and services to meet their needs.Furthermore, {Company Name} takes pride in its commitment to sustainability and environmental responsibility, and the Braided Tube Sleeve is manufactured in accordance with the highest standards of quality and environmental compliance. This ensures that businesses can rely on this product to not only deliver outstanding performance but also to meet their corporate social responsibility goals.In conclusion, {Company Name}’s Braided Tube Sleeve is a top-of-the-line solution for businesses looking to enhance the durability and protection of their industrial equipment. Its exceptional performance, versatility, and ease of use make it a valuable addition to any industrial operation, and the company’s commitment to customer support and environmental responsibility further positions it as a trusted partner for businesses across various industries. For businesses looking for a reliable and effective solution to protect their hoses, cables, and wires, the Braided Tube Sleeve from {Company Name} is the ideal choice.

High-Quality Electrical Wire Fiberglass Insulation Sleeving for Maximum Protection

The use of electrical wire fiberglass insulation sleeving has become increasingly popular in the electrical industry due to its high-quality insulation properties, durability, and flexibility. This type of sleeving is commonly used to protect wires and cables from environmental and mechanical damage, as well as provide an extra layer of insulation to prevent electrical shock or fire hazards.{Company Name} has been at the forefront of producing high-performance electrical wire fiberglass insulation sleeving for over two decades. With a strong focus on research and development, the company has continually improved its products to meet the ever-changing demands of the electrical industry. Their electrical wire fiberglass insulation sleeving is designed to provide reliable insulation in a wide range of temperatures, making it suitable for use in various applications such as automotive, aerospace, electronics, and industrial equipment. The sleeving is manufactured using high-quality fiberglass materials that are resistant to heat, chemicals, and abrasion, ensuring the long-term performance and safety of electrical components.In addition to its insulation properties, {Company Name}'s electrical wire fiberglass insulation sleeving is also highly flexible, allowing for easy installation and maintenance. The sleeving can be easily cut to size and bent around tight corners without compromising its integrity, making it a cost-effective solution for protecting and insulating electrical wiring in confined spaces.Furthermore, {Company Name} is committed to sustainability and environmental responsibility in its manufacturing processes. The company utilizes advanced technologies to minimize waste and emissions, and all of its products comply with international environmental regulations and standards. This dedication to sustainability has earned {Company Name} a reputation for being an environmentally conscious and socially responsible manufacturer in the electrical industry.As the demand for high-quality electrical wire insulation continues to grow, {Company Name} remains dedicated to meeting the needs of its customers with innovative and reliable products. With a strong emphasis on quality control and customer satisfaction, the company has built a loyal customer base that trusts in the performance and reliability of its electrical wire fiberglass insulation sleeving.In conclusion, {Company Name} is a leading manufacturer of electrical wire fiberglass insulation sleeving, offering a wide range of high-performance products designed to meet the stringent requirements of the electrical industry. With a focus on quality, flexibility, and sustainability, the company has positioned itself as a trusted and reliable supplier of electrical insulation solutions for a variety of applications. As the industry continues to evolve, {Company Name} is poised to remain at the forefront of innovation and excellence in electrical wire insulation technology.

New Crush Shield Technology Offers Advanced Protection for Safety and Security

Introducing the Next Generation of Safety: Crush ShieldAs the world continues to advance in technology, it is only appropriate that safety measures evolve as well. This is exactly what Crush Shield aims to do with its innovative product that is revolutionizing the way we think about safety. With a combination of advanced engineering and high-quality materials, Crush Shield is setting a new standard for protecting individuals and property from potential harm.{Company introduction} is a leading force in the development of cutting-edge safety solutions, and Crush Shield is a shining example of their dedication to creating products that make the world a safer place. With a team of experienced engineers and designers, they have successfully developed a product that has the potential to change the landscape of safety technology.So, what exactly is Crush Shield? At its core, Crush Shield is a state-of-the-art protective barrier that is designed to absorb and disperse impact energy in the event of a collision or accident. Whether it's a vehicle crashing into a building or a piece of heavy machinery colliding with a barrier, Crush Shield is engineered to minimize the damage and protect both people and property.One of the key features of Crush Shield is its versatility. It can be customized and tailored to fit a wide range of applications, making it a viable option for a variety of industries, including automotive, construction, and public safety. This flexibility is a testament to the company's commitment to creating solutions that can adapt to the diverse needs of their clients.In addition to its adaptability, Crush Shield is also designed with durability in mind. Constructed from high-strength materials, it is able to withstand significant impact forces while retaining its structural integrity. This level of resilience is a crucial factor in ensuring that Crush Shield can provide the level of protection that it promises.Though Crush Shield is already making waves in the safety industry, {Company introduction} has plans to continue pushing the boundaries of what is possible. They are constantly seeking new ways to improve and enhance their products, with a focus on integrating the latest advancements in materials and engineering. Their commitment to innovation means that the future of safety technology is in good hands.The impact of Crush Shield extends far beyond its physical presence. Beyond providing a tangible layer of protection, it offers peace of mind and reassurance to those who utilize it. Whether it's a business owner safeguarding their storefront or a city planner implementing safety measures on a busy street, Crush Shield represents a powerful step towards creating a safer and more secure world.The reception to Crush Shield has been overwhelmingly positive, with businesses and organizations across the globe expressing interest in integrating it into their safety protocols. As awareness of its capabilities continues to grow, there is no doubt that Crush Shield will become a pivotal component in the ongoing effort to mitigate risk and enhance safety standards.In conclusion, Crush Shield represents a new chapter in the evolution of safety technology. With its exceptional durability, versatility, and potential for widespread use, it has the power to make a significant impact in various industries. It is the culmination of meticulous engineering, innovative design, and a unwavering dedication to protecting people and property. As Crush Shield continues to gain traction, it is clear that the future of safety is brighter than ever.

Durable Textile for Protecting Harnesses: A Closer Look at the Latest Innovation

Harness Protection Textile, also known as HPT, is a revolutionary new material that is set to transform the world of industrial safety. Developed by a leading textile manufacturing company, HPT is specifically designed to provide exceptional protection for workers in industries that involve harnesses and other safety equipment. This innovative textile is the result of years of research and development, and it is poised to make a significant impact on workplace safety standards.The company behind HPT has a long history of producing high-quality textiles for various industries. With a strong focus on innovation and product development, the company has built a reputation for producing cutting-edge materials that meet the evolving needs of the market. By leveraging their expertise and state-of-the-art manufacturing facilities, the company has been able to create HPT, a material that offers unmatched protection and durability.HPT is engineered to provide superior protection for workers who rely on harnesses and safety equipment to perform their jobs safely. The material is designed to withstand the rigors of industrial environments, including exposure to harsh chemicals, extreme temperatures, and various types of physical stress. By incorporating advanced weaving techniques and specialized coatings, HPT offers exceptional resistance to abrasion, tearing, and punctures, ensuring that workers can depend on their safety equipment in any situation.In addition to its impressive protective properties, HPT is also designed with comfort and usability in mind. The material is lightweight and flexible, allowing for a full range of movement without impeding the wearer. Furthermore, it is breathable and moisture-wicking, which helps to keep workers comfortable and dry during long shifts. This combination of protection and comfort makes HPT an ideal choice for workers who rely on harnesses and safety equipment as part of their daily routine.The development of HPT represents a significant advancement in the field of industrial safety. By providing a reliable and durable material for harness protection, the company is helping to raise the standard for workplace safety across a wide range of industries. With HPT, workers can feel confident that they are equipped with the best possible protection, allowing them to focus on their work without worrying about their safety equipment failing them.Furthermore, the company's commitment to quality and innovation is evident in the development of HPT. By investing in research and development, as well as cutting-edge manufacturing processes, the company has been able to create a material that sets a new benchmark for harness protection. This dedication to excellence has earned the company a reputation as a trusted leader in the industry, and their products are relied upon by workers and businesses around the world.Looking ahead, the company is poised to continue driving innovation in the field of industrial textiles. With a strong focus on research and development, as well as a dedication to meeting the evolving needs of the market, the company is well-positioned to introduce new and improved materials that will further enhance workplace safety. By staying at the forefront of technological advancements, the company is committed to making a positive impact on the safety and well-being of workers in a variety of industries.In conclusion, the introduction of Harness Protection Textile represents a significant milestone in the field of industrial safety. Developed by a leading textile manufacturing company, HPT is a durable, protective, and comfortable material that is designed to meet the needs of workers who rely on harnesses and safety equipment. With a strong focus on innovation and product development, the company behind HPT has established itself as a trusted leader in the industry. Moving forward, the company is poised to continue driving advancements in industrial textiles, further solidifying its position as an industry innovator.

Discover the Benefits of an Abrasion Resistant Sleeve for Maximum Protection

Title: Industry-Leading Abrasion Resistant Sleeve Revolutionizes Material ProtectionIntroduction:In today's dynamic industrial landscape, the need for robust and reliable equipment is paramount to ensure smooth operations and long-lasting performance. Recognizing this critical requirement, an innovative industry leader in protective solutions has developed a groundbreaking Abrasion Resistant Sleeve. This game-changing product is set to revolutionize material protection across diverse sectors, setting new benchmarks for durability, reliability, and enhanced productivity.Body:1. Unmatched Durability & Superior Protection:The newly introduced Abrasion Resistant Sleeve surpasses all comparable solutions on the market by offering unparalleled durability and reliable protection. Engineered with cutting-edge technology, this revolutionary product is designed to withstand the harshest conditions, shielding fragile materials from the adverse effects of abrasion, friction, and external elements. Its robust construction and high-resistance properties ensure longevity, reducing downtime and maintenance costs for industries ranging from manufacturing to mining.2. Enhanced Flexibility & Versatility:Unlike conventional protective sleeves, this next-generation solution offers remarkable flexibility without compromising on strength. The innovative design allows for easy installation, providing a hassle-free experience for operators seeking quick and efficient material safeguarding. Moreover, the enhanced flexibility of the Abrasion Resistant Sleeve enables its seamless integration into a variety of applications, including hydraulic hoses, cables, wires, and tubes. This versatility makes it an ideal choice across numerous industries, catering to individual requirements and minimizing the need for multiple specialized solutions.3. Advanced Materials & Engineering:The Abrasion Resistant Sleeve owes its exceptional protective qualities to the use of state-of-the-art materials. Incorporating industry-leading engineering techniques, this cutting-edge product offers unmatched tensile strength and resistance against abrasion, cuts, and tears. By utilizing a combination of high-quality polymers and performance-enhancing additives, the sleeve provides a sturdy, yet lightweight solution that ensures maximum protection even in high-intensity environments. Its flame retardant and chemically resistant properties further contribute to its wide-ranging applicability.4. Cost-effective Solution & Sustainability:Apart from its superior performance capabilities, the Abrasion Resistant Sleeve stands out as a cost-effective choice for industries seeking long-term value. Its robust construction and resistance to wear and tear translate into reduced replacement costs and increased operational efficiency. Furthermore, its sustainability credentials cannot be understated. By extending the life cycle of crucial equipment and minimizing environmental impact through the reduction of waste, this innovative sleeve aligns with the growing demands for eco-friendly practices without compromising on performance.5. Future Applications & Market Potential:With its game-changing attributes, the Abrasion Resistant Sleeve is expected to witness significant adoption across various sectors. The manufacturing industry, in particular, stands to benefit greatly from this groundbreaking solution as it enhances the lifespan and efficiency of equipment critical to streamlined production processes. Moreover, the mining, construction, and energy industries can capitalize on the sleeve's robust properties to safeguard cables, hoses, and wires in high-demand environments. As demand grows, further research and development efforts are likely to expand the product's capabilities and applications.Conclusion:The introduction of the Abrasion Resistant Sleeve marks a milestone in material protection, offering unsurpassed durability, flexibility, and longevity to industries in need of robust solutions. With its advanced materials and engineering, this revolutionary product promises to overcome the limitations of traditional protective sleeves, ensuring increased operational efficiency, reduced downtime, and substantial cost savings. As companies look to optimize productivity and embrace sustainable practices, the Abrasion Resistant Sleeve emerges as a frontrunner in the realm of material protection, empowering industries to thrive in a competitive and ever-evolving landscape.

High-Quality Woven Tape: The Latest in Textile Innovation

Woven Tape, an essential material in the textile and garment industry, is one of the important elements in the manufacturing of clothing, bags, shoes, and other products. It is a type of narrow fabric that is woven on a loom, and it comes in various widths, colors, and patterns. Woven Tape is often used for decorative and functional purposes in the construction and design of various products.Woven Tape has a wide range of applications, from adding a decorative touch to clothing and accessories to providing reinforcement and support in industrial and technical products. Its versatility and strength make it a popular choice for manufacturers across different industries.{Company Name} is a leading manufacturer and supplier of Woven Tape in the textile and garment industry. With a focus on quality and innovation, {Company Name} has established itself as a trusted partner for businesses looking for high-quality woven tapes for their products. The company has a strong track record of delivering exceptional products and services to its clients, and it continues to push the boundaries of what is possible in the world of woven textiles.One of the key factors that set {Company Name} apart from its competitors is its commitment to providing sustainable and environmentally friendly products. The company takes pride in using eco-friendly materials and processes in its manufacturing operations, ensuring that its products have minimal impact on the environment. This dedication to sustainability has made {Company Name} a preferred choice for businesses that prioritize eco-conscious practices in their supply chain.In addition to its commitment to sustainability, {Company Name} places a strong emphasis on product quality and customer satisfaction. The company invests in state-of-the-art technology and equipment to ensure that its woven tapes meet the highest standards of durability, strength, and performance. Furthermore, {Company Name} has a team of skilled and experienced professionals who are dedicated to providing excellent customer service and support, ensuring that clients receive the best possible experience when working with the company.{Company Name}'s range of woven tapes includes various types and styles, catering to the diverse needs of its clients. Whether it's a standard woven tape for everyday use or a custom-designed tape for a specific application, {Company Name} has the expertise and resources to deliver tailored solutions that meet its clients' unique requirements. The company's extensive selection of colors, patterns, and finishes gives businesses the flexibility to choose the perfect woven tape for their products, enhancing their aesthetics and functionality.Furthermore, {Company Name} is continuously investing in research and development to stay ahead of industry trends and innovations. The company collaborates with designers, manufacturers, and industry experts to explore new materials, techniques, and designs, ensuring that its range of woven tapes remains at the forefront of the market. This commitment to innovation enables {Company Name} to offer cutting-edge solutions that help its clients stand out in a competitive marketplace.As the demand for high-quality woven tapes continues to rise, {Company Name} remains dedicated to providing exceptional products and services to its clients. With a strong focus on sustainability, product quality, customer satisfaction, and innovation, the company is well-positioned to meet the evolving needs of businesses in the textile and garment industry. Whether it's for fashion, technical, or industrial applications, {Company Name}'s woven tapes are the go-to choice for businesses looking for reliable, sustainable, and aesthetically pleasing solutions for their products.

Discover the Latest Advancements in Automotive Wiring Sleeve Technology

Title: Automotive Wiring Sleeve Revolutionizes Vehicle Circuit ProtectionIntroduction:In today's competitive automotive industry, manufacturers are constantly seeking innovative ways to improve safety, reliability, and performance. One company, renowned for its cutting-edge technology and dedication to excellence, is leading the charge with its revolutionary Automotive Wiring Sleeve. This product not only enhances circuit protection but also simplifies installation processes, ensuring vehicles are equipped with the highest level of electrical safety. Let's delve deeper into the features and benefits of this groundbreaking solution.Enhanced Protection for Vehicle Wiring:The Automotive Wiring Sleeve offers advanced protection against abrasion, moisture, heat, and other potential hazards that can compromise the integrity of a vehicle's wiring system. With stringent automotive industry standards in mind, the company has utilized high-quality materials that provide exceptional durability and resistance to various environmental factors.The sleeve is engineered with a combination of flame-retardant polyethylene and heat-resistant fibers. This design ensures that the wiring inside remains secure and free from any potential damage caused by extreme temperatures or external elements. By shielding the cables against abrasion, the sleeve contributes to prolonging their lifespan, avoiding costly repairs or replacements down the line.Streamlining Installation with Innovative Design:Installing the Automotive Wiring Sleeve is a breeze, thanks to its innovative design that simplifies the process for both manufacturers and technicians. The sleeve is flexible, allowing for easy routing of wires in complex automotive systems. Its self-wrapping feature eliminates the need for separate fasteners or adhesive tapes, saving time while ensuring a secure and tidy installation.Additionally, the sleeve is compatible with various wire configurations, enabling versatile use across different vehicle models. Manufacturers can significantly reduce assembly time, consequently boosting productivity without compromising on quality. Technicians can also appreciate the ease of maintenance and troubleshooting, as the sleeve can be easily repositioned or removed, providing convenient access to the wiring underneath.Emphasizing Electrical Safety:Electrical safety is paramount in automotive engineering, and the Automotive Wiring Sleeve plays a crucial role in minimizing potential hazards. The sleeve's insulating properties prevent wires from coming into contact with other components, thus reducing the risk of short circuits, electrical fires, or malfunctions. This robust safeguard ensures that vehicles equipped with this sleeve adhere to the highest safety standards mandated by regulatory bodies.Moreover, by securing the wiring against abrasion and external damage, the sleeve also prevents potential electrical leakages. This reduces the chances of intermittent failures, which can contribute to unexpected vehicle malfunctions and safety hazards for both drivers and passengers.Conclusion:The Automotive Wiring Sleeve represents a significant advancement in automotive electrical systems, providing enhanced circuit protection, simplified installation, and improved overall safety. Its durability, flexibility, and compatibility with various wire configurations make it an invaluable asset for manufacturers seeking to streamline production processes while placing a strong emphasis on quality.By incorporating this revolutionary product into their vehicles, manufacturers can demonstrate their commitment to ensuring the highest level of electrical safety for consumers. Furthermore, technicians will appreciate the unparalleled ease of installation and maintenance offered by the sleeve, resulting in improved efficiency and reduced troubleshooting time.With the Automotive Wiring Sleeve, the future of vehicle circuit protection looks brighter than ever, setting new industry standards and fostering a safer automotive landscape for everyone.

New Multilayer Braided Fabric Allows for Customizable Strength and Durability

Title: Groundbreaking Composite Braid Revolutionizes Multiple IndustriesIntroduction:The composite materials industry has recently witnessed a groundbreaking development with the emergence of a revolutionary product called the Composite Braid. This innovative solution has the potential to significantly transform various industries by offering enhanced strength, durability, and versatility. Developed by a prominent materials technology company, the Composite Braid is poised to revolutionize fields such as aerospace, automotive, and construction.(Company Name), a leader in advanced materials technology, has introduced the Composite Braid, a game-changing product that combines cutting-edge materials science with innovative manufacturing techniques. This composite braid is poised to redefine the way industries approach designing and constructing high-performance components, as it outperforms conventional materials in various aspects.1. Aerospace Industry:The aerospace sector stands to benefit immensely from the revolutionary Composite Braid. With its exceptional strength-to-weight ratio and resistance to extreme temperatures, this advanced material has the potential to push the boundaries of aviation technology. Aircraft structures reinforced with the Composite Braid will be significantly lighter and more fuel-efficient, while maintaining the necessary structural integrity to withstand high-stress conditions. By enabling manufacturers to reduce weight and maximize fuel efficiency, the Composite Braid can pave the way for more sustainable and cost-effective air travel.2. Automotive Industry:In the automotive industry, the Composite Braid offers the potential for significant improvements in vehicle safety, performance, and energy efficiency. Merging the Composite Braid with traditional manufacturing processes allows for the creation of lightweight, yet exceptionally strong vehicle components. Enhancing the structural integrity of automobiles can lead to enhanced safety during collisions, reducing the risk of injuries for passengers. Additionally, reduced weight results in improved fuel economy, lessening environmental impact and decreasing operating costs for consumers.3. Construction & Infrastructure:The Composite Braid holds great promise for the construction and infrastructure sectors. Traditional materials, such as steel and concrete, often face challenges in terms of weight, corrosion, and limited lifespan. By utilizing the Composite Braid, builders can construct structures that are not only stronger but also more durable and resistant to environmental factors. Its corrosion-resistant properties and high strength make it an ideal material for reinforcing bridges, buildings, and other critical infrastructure, ensuring their longevity and reliability.Furthermore, the versatility of the Composite Braid allows for the creation of complex and intricate architectural designs that were previously unattainable. Architects and designers now have the opportunity to push the boundaries of creativity while maintaining necessary structural integrity.4. Manufacturing & Engineering:Beyond its applications in aerospace, automotive, and construction, the Composite Braid offers numerous advantages to the wider manufacturing and engineering sectors. Its adaptability and ease of use provide opportunities for engineers and designers to create unique and customized solutions for various applications, including sporting goods, energy storage, and medical devices. The Composite Braid's superior strength and durability ensure long-lasting performance and reliability even under extreme conditions.Conclusion:The introduction of the Composite Braid marks a significant advancement in the field of composite materials, holding immense potential to revolutionize various industries. Its lightweight, high-strength properties combined with its adaptability and resistance to environmental factors make it a game-changer across aerospace, automotive, construction, and numerous other sectors. With this revolutionary technology, (Company Name) has redefined the possibilities for design, manufacturing, and innovation, driving industries toward a more sustainable and efficient future.