Durable Fire Resistant Fabric for Ultimate Protection

By:Admin

[Company Name], a leading manufacturer in the textile industry, is proud to introduce their latest innovation in fabric technology - the fire-resistant fabric. This breakthrough in fabric development comes after years of research and development, and is set to revolutionize the safety and protection industry.

The fire-resistant fabric by [Company Name] is designed to provide an extra layer of protection in environments where the risk of fire is a concern. Whether it's for industrial workers, firefighters, or even the everyday consumer, this fabric is engineered to withstand high temperatures and resist the spread of flames. This means that in the event of a fire, the fabric will help to minimize the risk of burns and injuries, offering a peace of mind to those who wear it.

What sets this fire-resistant fabric apart is not only its exceptional performance, but also its comfort and durability. Many existing fire-resistant fabrics on the market are often stiff and uncomfortable, making it difficult for the wearer to move around freely. However, the fabric developed by [Company Name] is designed with both safety and comfort in mind, ensuring that it is wearable for long periods of time without sacrificing protection.

The durability of the fabric is also noteworthy, as it can withstand repeated exposure to heat and flames without compromising its performance. This makes it an ideal choice for industries such as oil and gas, construction, and manufacturing, where workers are constantly at risk of fire-related accidents.

[Company Name]'s fire-resistant fabric is also designed to be easy to care for, making it suitable for everyday use. Unlike other fire-resistant fabrics that require special washing and maintenance, this fabric can be cleaned and maintained just like any other regular fabric, saving both time and money for the user.

In addition to its practical applications, the fire-resistant fabric by [Company Name] also boasts a range of environmental benefits. It is manufactured using sustainable practices and materials, making it a responsible choice for those who are conscious about their environmental footprint.

With this new addition to their product line, [Company Name] further solidifies their position as a leader in textile innovation. Their commitment to pushing the boundaries of what is possible in fabric development has earned them a reputation for excellence in the industry. This latest creation is a testament to their dedication to providing high-quality, cutting-edge solutions to their customers.

The fire-resistant fabric by [Company Name] is now available for purchase, and is set to make a significant impact in a wide range of industries. Whether it's for workwear, uniforms, or personal protective equipment, this fabric provides an extra layer of safety that is unmatched in the market.

For more information about [Company Name] and their fire-resistant fabric, please visit their website or contact their customer service team.

Company News & Blog

Durable and Versatile Copper Braided Sleeve for Various Applications

{Company Introduction} is a leading manufacturer and supplier of high-quality protective sleeving solutions for a wide range of industries. With a focus on innovation and customer satisfaction, the company has built a strong reputation for delivering products that exceed expectations. Their extensive range of braided sleeves and other protective solutions are designed to provide durable and reliable protection for cables, hoses, and other vital components.In line with their commitment to quality and innovation, {Company} is proud to announce the launch of their latest product, the Copper Braided Sleeve. This new addition to their range offers an advanced level of protection for cables and wires in demanding industrial environments.The Copper Braided Sleeve is constructed from high-quality copper material, providing excellent electromagnetic shielding and thermal conductivity. This makes it an ideal solution for applications where electrical interference and heat resistance are critical, such as in the aerospace, automotive, and telecommunications industries. The braided design of the sleeve allows for flexibility and expandability, ensuring a snug and secure fit around cables of varying sizes."We are excited to introduce our Copper Braided Sleeve to the market," said {Company} CEO. "This product is the result of extensive research and development, and we believe it offers a superior level of protection for our customers' valuable equipment and components."In addition to its exceptional protective properties, the Copper Braided Sleeve is also designed for ease of installation. Its flexible and lightweight construction allows for quick and simple fitting, saving time and labor costs for customers. The sleeve is also resistant to abrasion and UV radiation, ensuring long-lasting performance in even the harshest environments.{Company} is dedicated to providing tailored solutions to meet the unique needs of their customers, and the Copper Braided Sleeve is no exception. The company offers customization options for the sleeve, including different lengths, diameters, and colors to suit specific requirements. This flexibility ensures that customers can find the perfect protective solution for their individual applications.As with all of their products, {Company} has subjected the Copper Braided Sleeve to rigorous testing to ensure its durability and reliability. The sleeve meets the highest quality standards and is designed to withstand the demands of industrial usage, providing peace of mind for customers in even the most challenging environments.The launch of the Copper Braided Sleeve further solidifies {Company}'s position as a leading provider of protective sleeving solutions. With a commitment to innovation, quality, and customer satisfaction, the company continues to set new standards in the industry and provide cutting-edge solutions for a wide range of applications."We are proud to offer the Copper Braided Sleeve as part of our comprehensive range of protective sleeving solutions," said {Company} CEO. "This product exemplifies our dedication to meeting the evolving needs of our customers and providing them with the highest quality products to safeguard their valuable assets."Customers seeking a reliable and high-performance solution for cable and wire protection can trust {Company} to deliver the best products on the market. The Copper Braided Sleeve is now available for purchase, and {Company} welcomes inquiries from businesses looking to enhance the protection of their critical equipment with this advanced solution. With a commitment to excellence and a track record of delivering superior products, {Company} is the go-to source for all protective sleeving needs.

Discover the Benefits of Fiberglass Sleeving for Electrical Applications

[Company Introduction][Company Name] is a leading manufacturer and supplier of high-quality industrial materials. With over [number] years of experience in the industry, we strive to provide our customers with innovative solutions and top-notch products.Our commitment to excellence and customer satisfaction has earned us the trust and loyalty of businesses worldwide. We take pride in our extensive range of products, which includes [product categories]. From electrical insulation materials to mechanical protection solutions, we cater to various industries, meeting their diverse needs and requirements.Our state-of-the-art manufacturing facility, equipped with cutting-edge technology and skilled professionals, ensures that our products are of the highest standard. With a strong emphasis on quality control measures, we conduct rigorous testing at every stage of the production process to ensure optimal performance and reliability.At [Company Name], we believe in sustainable practices and responsible manufacturing. We are committed to minimizing our environmental impact and continuously improving our processes to adopt greener alternatives. Our dedication to sustainability extends to the materials we use, including our range of Fibreglass Sleeving.[Introduction to Fibreglass Sleeving]Fibreglass Sleeving is a versatile and highly durable electrical insulation material that finds applications across various industries. Designed to safeguard electrical components from heat, chemicals, and abrasions, this sleeving provides dependable protection in demanding environments.Key Features of Fibreglass Sleeving:1. High Temperature Resistance: Fibreglass Sleeving is known for its exceptional resistance to high temperatures. This makes it suitable for use in applications where prolonged exposure to heat is expected, such as in motors, transformers, and generators.2. Electrical Insulation: The insulating properties of Fibreglass Sleeving make it ideal for electrical applications, where it effectively prevents current leakage and enhances safety. It ensures the efficient functioning of electrical systems, minimizing the risk of shorts and malfunctions.3. Chemical Resistance: Fibreglass Sleeving demonstrates excellent resistance to a wide range of chemicals, making it an ideal choice for industries that deal with corrosive substances. It provides a protective layer that shields electrical components from chemical damage, extending their lifespan.4. Mechanical Protection: The robust nature of Fibreglass Sleeving offers mechanical protection to wires and cables. It resists wear and tear caused by abrasion, thereby ensuring the longevity of the components and enhancing their reliability.5. Flexibility and Expandability: Fibreglass Sleeving is available in various sizes and configurations, allowing for easy installation and fitting onto different wire diameters. Its expandability ensures a snug fit, offering excellent coverage and protection.Applications of Fibreglass Sleeving:1. Electrical Equipment: Fibreglass Sleeving is widely used in electrical equipment, including motors, generators, transformers, and coils. It ensures insulation, protection, and heat resistance in these critical components.2. Automotive Industry: The automotive industry heavily relies on Fibreglass Sleeving for wire harnessing and insulation purposes. It provides a reliable barrier against heat, abrasion, and chemicals, thereby enhancing the performance and safety of vehicles.3. Electronic Appliances: Fibreglass Sleeving is utilized in electronic appliances such as kitchen appliances, televisions, and computers. It safeguards wiring connections and electrical components from heat and abrasions caused by regular usage.4. Industrial Applications: Various industrial sectors, such as aerospace, manufacturing, and telecommunications, benefit from Fibreglass Sleeving. Its high temperature resistance, electrical insulation, and durability make it a preferred choice for protecting wires and cables in these demanding environments.In conclusion, Fibreglass Sleeving offered by [Company Name] is a reliable and efficient choice for electrical insulation and mechanical protection. With its exceptional performance under high temperatures, chemical resistance, and flexibility, this sleeving ensures the long-term reliability of electrical components in various industries. At [Company Name], we strive to provide our customers with superior products backed by our dedication to quality and sustainability.

Essential Fire Protection Sleeves for Safety and Prevention

Fire Protection Sleeve (FPS), a leading provider of high-quality fire protection products, has become increasingly popular in the market for its innovative solutions in fire protection and safety. FPS has been dedicated to providing advanced fire protection products for industrial, commercial, and residential applications, and its commitment to excellence and customer satisfaction has made it a reliable partner for many businesses and homeowners.Established in 2005, FPS has quickly established itself as a trusted name in the fire protection industry. The company's mission is to develop and deliver high-performance fire protection products that meet the evolving needs of its customers. With a focus on innovation and quality, FPS has continuously expanded its product line to offer a comprehensive range of fire protection solutions, including fire sleeves, fire blankets, fire curtains, and fire seals.One of FPS's most popular products is the Fire Protection Sleeve, which is designed to provide fire resistance for cables, hoses, and pipes in the event of a fire. The Fire Protection Sleeve is made from a durable, heat-resistant material that can withstand high temperatures and protect critical equipment from the devastating effects of fire. The sleeve is easy to install and provides a reliable and cost-effective solution for safeguarding cables and hoses in industrial and commercial settings.The Fire Protection Sleeve is available in a variety of sizes and configurations to suit different applications, and it has been extensively tested to meet the stringent fire safety standards and regulations. With its proven performance and reliability, the Fire Protection Sleeve has become an essential component of fire protection systems in a wide range of industries, including oil and gas, automotive, aerospace, and construction.In addition to its high-quality products, FPS is also known for its commitment to customer service and support. The company's team of experienced professionals is dedicated to providing expert guidance and assistance to customers, helping them to select the right fire protection solutions for their specific needs. FPS also offers custom solutions and engineering support to ensure that its products meet the unique requirements of each application.Furthermore, FPS is committed to sustainability and environmental responsibility, and it continuously seeks to improve the environmental performance of its products and operations. The company is actively involved in research and development activities to create more eco-friendly fire protection solutions that minimize the impact on the environment.As FPS continues to grow and expand its presence in the market, it remains focused on its core values of integrity, excellence, and innovation. The company's ongoing investment in research and development, as well as its dedication to customer satisfaction, will ensure that it remains at the forefront of the fire protection industry.In conclusion, Fire Protection Sleeve (FPS) is a trusted and reliable provider of high-quality fire protection products, offering innovative solutions for a wide range of applications. With its dedication to excellence, customer satisfaction, and environmental responsibility, FPS is well-positioned to meet the evolving needs of the fire protection industry and continue its success in the market.

Ultimate Guide to Wire Sleeving: Everything You Need to Know

Wire Sleeving, also known as cable sleeving or wire harnessing, is a protective covering used to bundle and protect wires and cables. It is commonly used in various industries such as automotive, aerospace, and electronics to organize and protect wires from abrasion, heat, and other environmental elements. Wire sleeving also helps to improve the aesthetic appearance of wire assemblies and provides insulation for the wires.With the increasing demand for wire sleeving in various industries, companies like {} have emerged as leading providers of high-quality wire sleeving solutions. {} is a global company that specializes in the design, development, and manufacturing of wire sleeving products for a wide range of applications.Founded in 1990, {} has established itself as a trusted provider of wire sleeving solutions, offering a comprehensive range of products to meet the diverse needs of its customers. The company's extensive product line includes expandable braided sleeving, woven wrap sleeving, heat shrink tubing, cable ties, and accessories, all designed to provide maximum protection and organization for wires and cables.{}'s wire sleeving products are known for their durability, flexibility, and resistance to abrasion and high temperatures, making them ideal for use in demanding environments. The company's commitment to quality and innovation has earned it a strong reputation in the industry, and its products are widely used by leading manufacturers and professionals in various fields.In addition to its extensive product line, {} also offers custom fabrication services, allowing customers to create bespoke wire sleeving solutions tailored to their specific requirements. This flexibility sets {} apart from its competitors, as it can accommodate unique design needs and provide personalized solutions for its clients.With a focus on continuous improvement and customer satisfaction, {} invests in research and development to advance its wire sleeving technology and develop new products that meet the evolving needs of its customers. The company also prioritizes environmental sustainability in its manufacturing processes, ensuring that its products adhere to the highest standards of quality and safety.As a global leader in wire sleeving solutions, {} is dedicated to providing exceptional customer service and support, offering technical assistance and guidance to help customers select the right products for their applications. The company's commitment to excellence has earned it the trust and loyalty of its customers, who rely on {} for their wire sleeving needs.Looking ahead, {} is poised to continue its growth and expansion, leveraging its expertise and capabilities to serve new markets and industries. With a strong focus on quality, innovation, and customer satisfaction, {} is well-positioned to remain a top choice for wire sleeving solutions in the years to come. As the demand for wire sleeving continues to rise, {} is committed to meeting the evolving needs of its customers and delivering superior products that exceed expectations.In conclusion, wire sleeving plays a crucial role in protecting and organizing wires and cables in various industries, and companies like {} are leading the way in providing high-quality solutions for these applications. With a strong commitment to quality, innovation, and customer satisfaction, {} has earned a reputation as a trusted provider of wire sleeving products, and is well-positioned to meet the growing demand for these solutions in the global market.

Top Quality Electrical Wire Fiberglass Insulation Sleeving for Your Needs

[Company Name] Launches Innovative Electrical Wire Fiberglass Insulation Sleeving[City, Date] - [Company Name], a leading provider of high-quality electrical insulation products, is proud to announce the launch of their latest innovation - Electrical Wire Fiberglass Insulation Sleeving.The Electrical Wire Fiberglass Insulation Sleeving is a revolutionary product that provides superior insulation and protection for electrical wires. It is made from high-quality fiberglass material that is designed to withstand high temperatures and harsh environments, making it the ideal choice for a wide range of electrical applications."We are thrilled to introduce our new Electrical Wire Fiberglass Insulation Sleeving to the market," said [Company Spokesperson]. "This product is the result of our continuous commitment to innovation and providing our customers with the best possible solutions for their insulation needs."The Electrical Wire Fiberglass Insulation Sleeving is available in a variety of sizes and lengths to accommodate different wire diameters and lengths. It is also designed to be flexible and easy to install, making it a convenient choice for electrical professionals and DIY enthusiasts alike.In addition to its exceptional insulation properties, the Electrical Wire Fiberglass Insulation Sleeving also offers superior resistance to chemicals, oils, and solvents. This makes it a versatile option for a wide range of applications, including automotive, aerospace, marine, and industrial uses."At [Company Name], we understand the importance of reliable and durable insulation products," said [Company Spokesperson]. "Our Electrical Wire Fiberglass Insulation Sleeving is engineered to meet the highest standards of quality and performance, ensuring that our customers can trust it to protect their electrical components in even the most demanding environments."With the launch of the Electrical Wire Fiberglass Insulation Sleeving, [Company Name] continues to solidify its position as a leading provider of electrical insulation solutions. The company is dedicated to delivering products that not only meet industry standards but also exceed customer expectations in terms of performance and reliability.In addition to the Electrical Wire Fiberglass Insulation Sleeving, [Company Name] offers a comprehensive range of insulation products, including heat shrink tubing, silicone rubber tubing, and PVC tubing. The company also provides custom solutions to meet specific customer requirements, ensuring that they can always find the perfect insulation solution for their needs."We take great pride in our ability to offer a wide range of insulation products to our customers," said [Company Spokesperson]. "Our team is committed to providing exceptional service and support to help our customers find the right products for their projects, no matter how big or small."With its dedication to innovation, quality, and customer satisfaction, [Company Name] is poised to continue leading the way in the electrical insulation industry. The launch of the Electrical Wire Fiberglass Insulation Sleeving is just one example of the company's ongoing commitment to excellence and to providing the best possible solutions for its customers.For more information about [Company Name] and its range of insulation products, including the new Electrical Wire Fiberglass Insulation Sleeving, visit [Company Website] or contact the [Company Name] team directly at [Company Phone Number] or [Company Email Address].About [Company Name]:[Company Name] is a leading provider of high-quality electrical insulation products, serving customers in a wide range of industries. With a commitment to innovation, quality, and customer satisfaction, the company offers a comprehensive range of insulation solutions, including heat shrink tubing, silicone rubber tubing, PVC tubing, and custom products. Through exceptional service and support, [Company Name] continues to exceed customer expectations and lead the way in the electrical insulation industry.

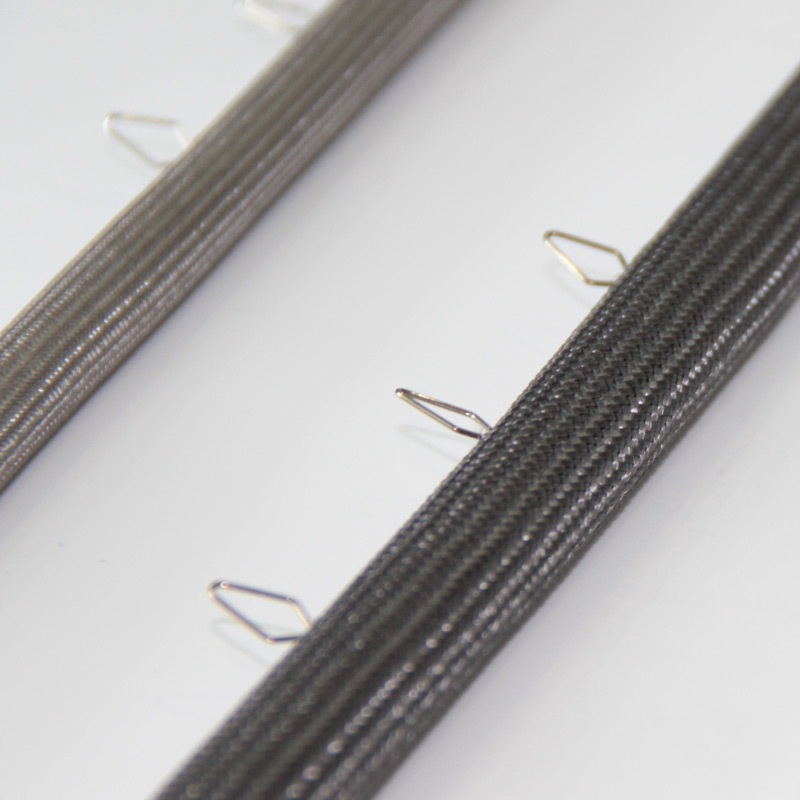

High Quality Carbon Braided Sleeve for Enhanced Protection and Durability

Carbon Braided Sleeve Combined with Company IntroductionThe use of advanced materials in various industries has become increasingly important in order to achieve high-performance results. One company that is at the forefront of developing and providing advanced materials is [Company Name]. The company has recently introduced a new product, the Carbon Braided Sleeve, which is set to revolutionize the way industries use composite materials.[Company Name] is a leading supplier of advanced composite materials and innovative solutions for a wide range of industries, including aerospace, automotive, marine, and industrial. The company has a strong focus on research and development, and its team of engineers and material scientists are dedicated to creating products that offer superior performance and durability.The Carbon Braided Sleeve is a prime example of the company's commitment to innovation and excellence. This new product is designed to provide high strength and stiffness while maintaining excellent resistance to chemicals and extreme temperatures. The sleeve is made from high-quality carbon fibers that are braided into a seamless, tubular shape, providing exceptional mechanical properties and structural integrity.The Carbon Braided Sleeve offers numerous benefits for industries looking to enhance the performance and durability of their products. It can be used to reinforce and protect a wide variety of structures, including pipes, tanks, and other composite materials. The sleeve is also ideal for use in applications that require lightweight, high-strength materials, such as in the aerospace and automotive industries.One of the key advantages of the Carbon Braided Sleeve is its ability to conform to complex shapes and contours, making it a versatile and easy-to-use solution for a wide range of applications. This adaptability allows for the efficient and cost-effective reinforcement of structures, without the need for complex and time-consuming manufacturing processes.In addition to its outstanding mechanical properties, the Carbon Braided Sleeve also offers excellent resistance to abrasion, impact, and fatigue. This makes it an ideal choice for applications where durability and long-term performance are essential. Furthermore, the sleeve is compatible with a variety of resin systems, allowing for easy integration into existing manufacturing processes.[Company Name] is dedicated to providing top-quality products and exceptional customer service. The company's team of experts works closely with clients to understand their specific needs and provide tailored solutions that meet or exceed their expectations. With the introduction of the Carbon Braided Sleeve, [Company Name] is poised to continue its tradition of delivering innovative, high-performance materials to industries around the world.The Carbon Braided Sleeve is now available for purchase and can be customized to meet the unique requirements of individual clients. With its exceptional mechanical properties and versatility, the sleeve is set to become an essential component in the manufacturing and production processes of numerous industries.[Company Name] is excited to introduce the Carbon Braided Sleeve to the market and looks forward to helping clients enhance the performance and durability of their products. With its focus on innovation and customer satisfaction, [Company Name] is well-positioned to remain a leader in the supply of advanced composite materials.In conclusion, the introduction of the Carbon Braided Sleeve by [Company Name] represents a significant advancement in the field of composite materials. This innovative product offers exceptional mechanical properties and versatility, making it an ideal choice for industries looking to enhance the performance and durability of their products. With its commitment to excellence and customer satisfaction, [Company Name] is set to continue its success as a leading supplier of advanced composite materials. So, the introduction of the Carbon Braided Sleeve represents an exciting new chapter in the company's ongoing commitment to innovation and excellence.

High-Quality Carbon Braided Sleeve for Durable and Efficient Performance

Carbon Braided Sleeve Provides Ultimate Protection for Industrial ApplicationsIn today's fast-paced industrial world, the need for reliable protection and reinforcement of critical components is more important than ever. To meet these demands, (company name) has developed an innovative solution that provides ultimate protection for industrial applications - the Carbon Braided Sleeve.The Carbon Braided Sleeve is a high-performance, lightweight, and durable solution that offers superior protection for hoses, cables, and wires in a variety of industrial environments. Made from high-quality carbon fiber, this braided sleeve is designed to withstand the harshest conditions and provide long-lasting protection for critical components.The Carbon Braided Sleeve is specifically engineered to provide excellent abrasion resistance, chemical resistance, and thermal insulation, making it ideal for a wide range of industrial applications. Whether it's protecting hoses and cables in automotive manufacturing, providing reinforcement for wires in aerospace applications, or enhancing the durability of cables in marine environments, the Carbon Braided Sleeve is the ultimate solution for reliable and long-lasting protection.One of the key advantages of the Carbon Braided Sleeve is its lightweight and flexible construction, which allows for easy installation and maintenance. The braided sleeve can be easily slipped over hoses, cables, and wires, providing a seamless and secure fit that will not impede the performance of the components it is protecting. This ease of installation makes the Carbon Braided Sleeve a cost-effective solution for industrial applications, as it requires minimal downtime and labor to implement.In addition to its superior protection and ease of installation, the Carbon Braided Sleeve also offers excellent resistance to high temperatures, making it an ideal solution for applications where heat resistance is critical. Whether it's protecting hoses and cables in high-temperature manufacturing environments or providing thermal insulation for wires in automotive applications, the Carbon Braided Sleeve provides reliable protection in even the most demanding conditions.Furthermore, (company name) is dedicated to providing high-quality, reliable solutions for industrial applications. With decades of experience in the industry, (company name) has a proven track record of delivering innovative products that meet the needs of its customers. The Carbon Braided Sleeve is a testament to (company name)'s commitment to excellence, as it represents the company's dedication to developing solutions that provide exceptional performance and reliability in industrial environments.In conclusion, the Carbon Braided Sleeve is a high-performance, lightweight, and durable solution that provides ultimate protection for industrial applications. With its superior abrasion resistance, chemical resistance, and thermal insulation, this innovative braided sleeve is the ideal solution for protecting critical components in a wide range of industrial environments. Furthermore, the Carbon Braided Sleeve's lightweight and flexible construction make it easy to install and maintain, while its excellent resistance to high temperatures ensures reliable protection even in the most demanding conditions. With (company name)'s dedication to excellence and proven track record of delivering high-quality solutions, the Carbon Braided Sleeve is the ultimate choice for reliable and long-lasting protection in industrial applications.

Protective Sleeve for Electrical Wires: A Must-Have for Safety

Electrical Wire Protector Sleeve Enhances Safety and Protection for Various ApplicationsElectrical wire protection is an essential aspect of ensuring safety and efficiency in any electrical system. With the increasing demand for reliable and durable wire protection solutions, [Company Name] has introduced a cutting-edge Electrical Wire Protector Sleeve that is designed to provide superior protection for a wide range of applications.[Company Name] is a leading manufacturer of innovative and high-quality wire protection products and solutions. With a strong focus on research and development, the company has been at the forefront of delivering advanced wire protection technologies to meet the evolving needs of the electrical industry. The Electrical Wire Protector Sleeve is the latest addition to [Company Name]'s extensive line of wire protection products, and it is poised to set new standards in the industry.The Electrical Wire Protector Sleeve is engineered to safeguard electrical wires and cables from various environmental and mechanical hazards. Constructed from high-quality materials, the sleeve is designed to resist abrasion, heat, chemicals, and UV rays, ensuring long-lasting protection and performance in diverse operating conditions. The sleeve is also flame-retardant, which adds an extra layer of safety to electrical systems.One of the key features of the Electrical Wire Protector Sleeve is its flexibility and ease of installation. The sleeve can be easily slipped over wires and cables, providing a seamless and secure fit. This flexibility allows for easy maintenance and accessibility to the wires when needed, making it a practical solution for a wide range of applications.The Electrical Wire Protector Sleeve is suitable for use in various industries, including automotive, industrial, marine, and aerospace. Its robust design and superior protection capabilities make it an ideal choice for applications where wires are subjected to harsh environments and rugged conditions. Whether it's protecting wires in heavy machinery or ensuring the safety of electrical systems in vehicles, the Electrical Wire Protector Sleeve is a versatile solution that meets the demands of diverse applications.Furthermore, [Company Name] offers customization options for the Electrical Wire Protector Sleeve to meet specific application requirements. This includes the ability to tailor the sleeve's dimensions, colors, and other features to suit the unique needs of different projects. With this level of customization, customers can benefit from a tailored wire protection solution that fits their exact specifications and preferences.In addition to its functional benefits, the Electrical Wire Protector Sleeve is also designed with aesthetics in mind. Its sleek and professional appearance makes it a visually appealing choice for applications where the appearance of wires and cables is important. This attention to detail sets the Electrical Wire Protector Sleeve apart as a comprehensive solution that encompasses both form and function.[Company Name]'s commitment to quality and innovation is reflected in the development of the Electrical Wire Protector Sleeve. The company's dedicated team of engineers and technical experts has worked tirelessly to create a product that exceeds industry standards and delivers exceptional performance. This dedication to excellence has earned [Company Name] a reputation for being a trusted provider of wire protection solutions.In conclusion, the introduction of the Electrical Wire Protector Sleeve by [Company Name] represents a significant advancement in wire protection technology. With its advanced features, versatility, and customizable options, the sleeve is poised to meet the diverse needs of various industries and applications. As electrical systems continue to evolve and expand, the Electrical Wire Protector Sleeve stands ready to provide the safety and protection required for reliable operation.

Durable and Reliable Electrical Insulating Sleeve for Sale

Electrical Insulating Sleeve Enhances Safety in Industrial EnvironmentsElectrical safety is of utmost importance in industrial settings, where workers are frequently exposed to high-voltage equipment and machinery. To address this concern, a leading provider of electrical insulation solutions, {} (company name), has introduced a new Electrical Insulating Sleeve that is designed to enhance safety and protect workers from electrical hazards.The Electrical Insulating Sleeve, which is manufactured using advanced materials and innovative technology, provides a reliable barrier against electrical currents and insulation from live conductors. This essential safety equipment is designed to be used in a wide range of industrial applications, including electrical maintenance, construction, and manufacturing.With a commitment to quality and safety, {} (company name) has developed this Electrical Insulating Sleeve to meet the highest industry standards and regulations. The company's dedication to excellence and continuous improvement is reflected in the design and performance of this new product.The Electrical Insulating Sleeve is constructed with durable and flexible materials that can withstand the rigors of industrial work environments. It is engineered to resist punctures, tears, and abrasions, ensuring long-lasting protection for workers exposed to electrical hazards. The sleeve's ergonomic design allows for easy installation and comfortable wear, enhancing worker productivity and safety.In addition to its superior protective qualities, the Electrical Insulating Sleeve also offers excellent dielectric strength and insulation properties. This makes it an ideal choice for electrical workers who require reliable protection against high voltage and electric shock hazards.The introduction of this new Electrical Insulating Sleeve demonstrates {}(company name)'s ongoing commitment to providing innovative solutions that enhance workplace safety and productivity. With a focus on customer needs and industry requirements, the company continues to invest in research and development to deliver cutting-edge products that address the evolving challenges of electrical safety in industrial settings."We are excited to launch our new Electrical Insulating Sleeve, which represents a significant advancement in electrical safety technology," said [Spokesperson's name], [Job title] at {}. "At {}, we understand the importance of protecting workers from electrical hazards, and we are proud to offer a solution that meets the highest standards of safety and performance."As a trusted leader in the field of electrical insulation, {}(company name) continues to be a preferred supplier for companies seeking reliable and effective safety solutions. The company's comprehensive range of products includes an extensive selection of electrical insulating materials, personal protective equipment, and accessories that are designed to mitigate the risks associated with electrical work.Through its dedication to innovation and excellence, {}(company name) has earned a reputation for delivering high-quality products that meet the specific needs of its customers. The company's commitment to safety and reliability has positioned it as a trusted partner for businesses across various industries, including energy, construction, manufacturing, and more.The introduction of the new Electrical Insulating Sleeve underscores {}(company name)'s ongoing dedication to advancing workplace safety and protecting workers from electrical hazards. By providing innovative solutions that combine quality, performance, and value, {}(company name) demonstrates its continued leadership in the electrical insulation industry.As businesses strive to maintain safe and productive work environments, the availability of reliable safety equipment such as the Electrical Insulating Sleeve is essential. With {}(company name)'s latest innovation, companies have access to a trusted solution that enhances electrical safety and ensures peace of mind for workers operating in high-voltage environments.For more information about {}(company name) and its range of electrical insulation solutions, please visit [Company website].Contact:[Contact person’s name][Job Title][Company Name][Contact information]

The Importance of EMI Shielding in Electronics: A Must-Know Guide

EMI Shielding, an essential component in today's electronic devices, has become a critical solution to protect sensitive electronics from electromagnetic interference (EMI). As technology continues to advance, the need for reliable EMI shielding materials has never been greater. At the forefront of this industry is a leading company that has been innovating and providing high-quality EMI shielding solutions for various applications.With a strong emphasis on research and development, [company name] has been a pioneer in the EMI shielding industry, offering a wide range of innovative products designed to meet the evolving needs of the electronics market. The company's commitment to quality, performance, and customer satisfaction has made them a trusted partner for many leading electronics manufacturers worldwide.One of the primary challenges in modern electronic devices is the increasing complexity and density of circuitry, which makes them more susceptible to EMI. As a result, the demand for effective EMI shielding solutions has been on the rise. [Company name]'s advanced EMI shielding materials are designed to effectively block unwanted electromagnetic interference, ensuring the reliable operation of sensitive electronic components in various environments.The company's extensive expertise in materials science and engineering has allowed them to develop a wide range of EMI shielding products, including conductive gaskets, conductive adhesives, and conductive coatings, among others. These products are designed to provide excellent shielding effectiveness while meeting the stringent requirements of modern electronic devices.In addition to standard EMI shielding solutions, [company name] also offers custom-designed products to meet the unique requirements of specific applications. Their team of expert engineers and technical staff work closely with customers to develop tailored solutions that address their specific EMI shielding needs, ensuring optimal performance and reliability.Furthermore, [company name] is committed to sustainability and environmental responsibility, and their EMI shielding materials are designed to comply with the industry's strictest environmental regulations. By using sustainable materials and manufacturing processes, the company is dedicated to minimizing its environmental footprint while delivering high-quality, reliable EMI shielding solutions.As the electronics industry continues to evolve, [company name] remains at the forefront of innovation, constantly developing new and advanced EMI shielding materials to meet the ever-changing needs of the market. With a strong focus on technological advancement and customer satisfaction, the company is well-positioned to maintain its leadership in the EMI shielding industry.In conclusion, EMI shielding plays a crucial role in ensuring the reliable operation of modern electronic devices, and [company name] has been a key player in providing high-quality, innovative EMI shielding solutions. With a strong emphasis on research and development, as well as a commitment to quality and sustainability, the company continues to be a trusted partner for electronics manufacturers worldwide. As technology continues to advance, [company name] is well-prepared to meet the growing demand for reliable EMI shielding materials, further solidifying its position as a leader in the industry.