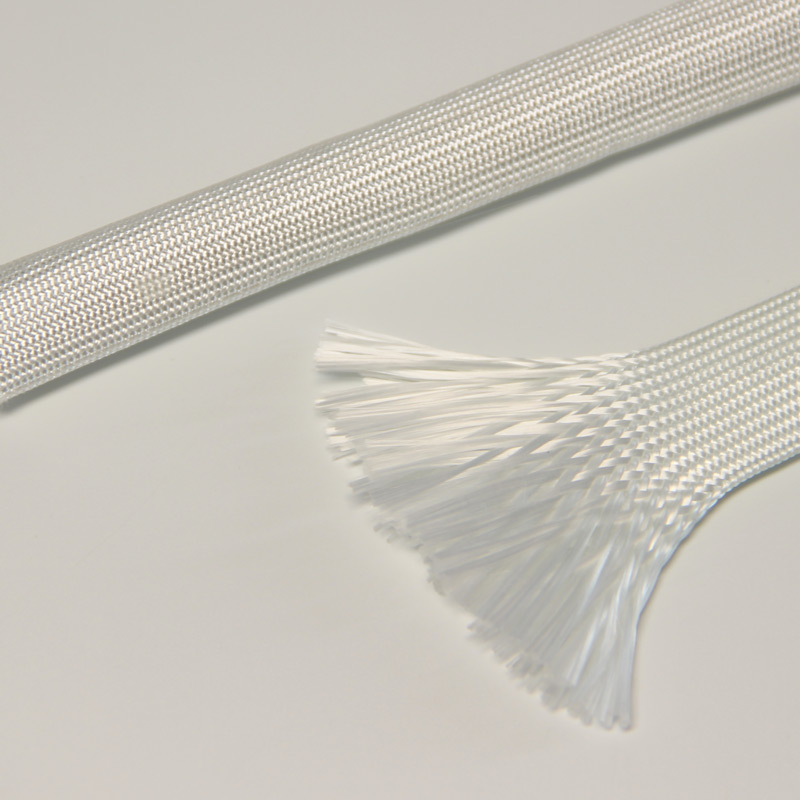

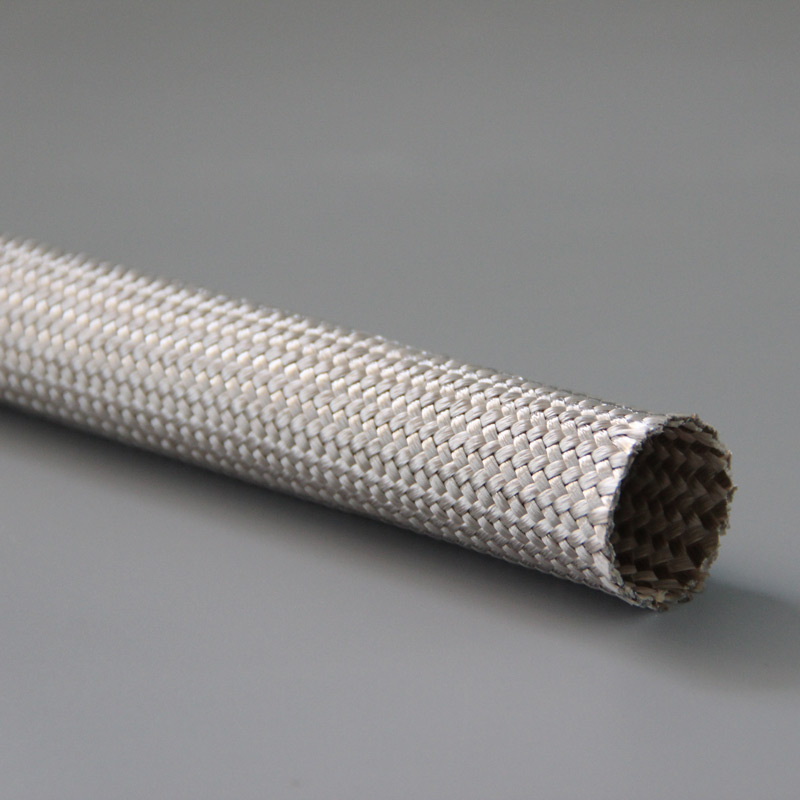

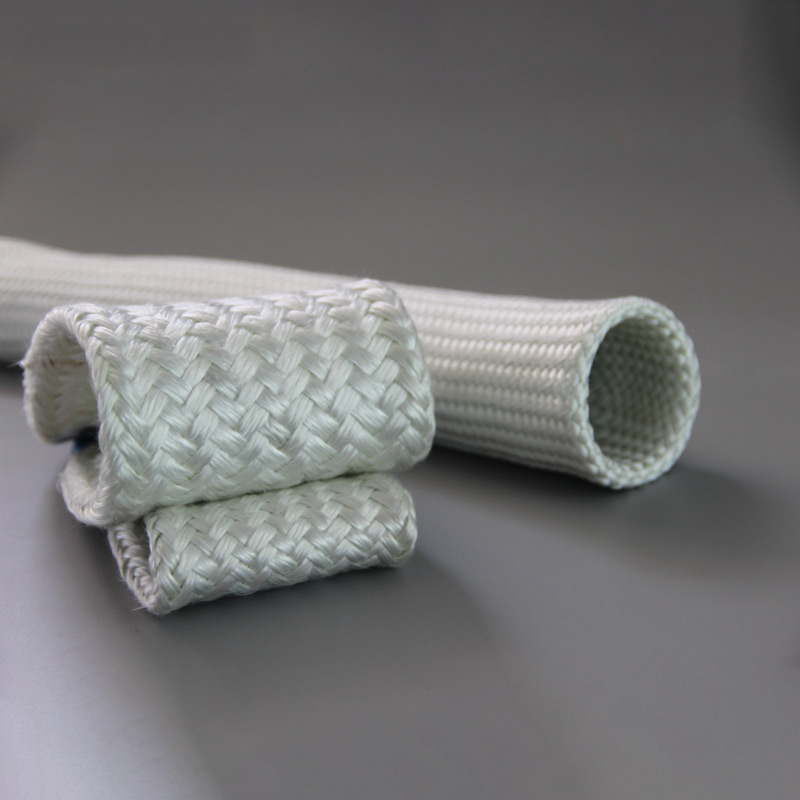

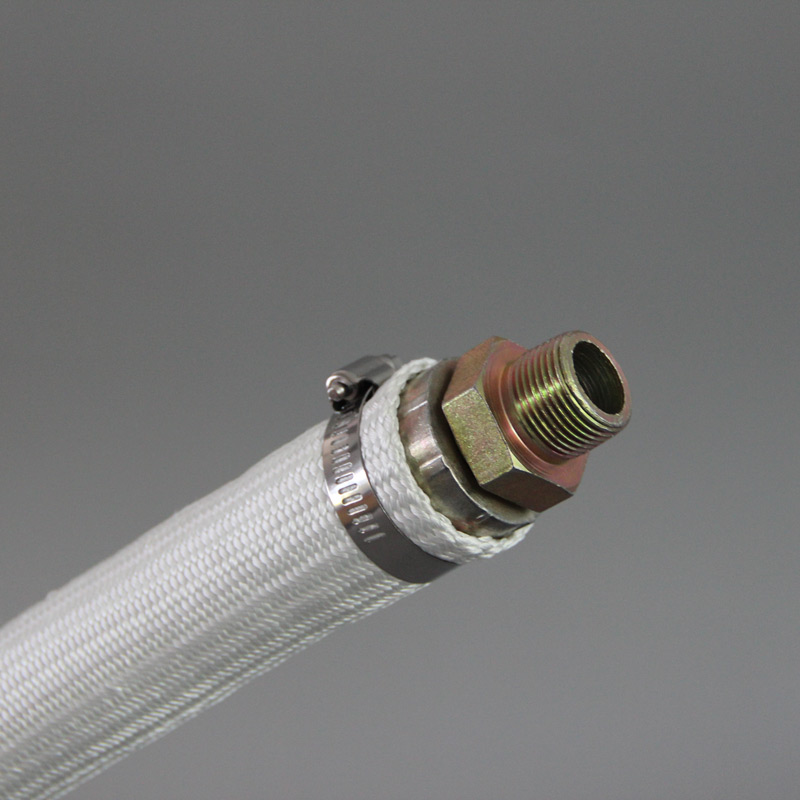

Glassflex with High Modulus Characteristic and High Temperature Resistance

Shop Glassflex with high modulus characteristic and high temperature resistance at our factory. Get the best quality products for your needs.

Request a QuotePRODUCTS DETAILS

Hot Products

Glassflex with High Modulus Characteristic and High Temperature Resistance

Oven gaskets, Tadpole gasket, round gasket with wire core and cord core, glass seal

Thermtex braided tape for oven self adhesive heat resistant strip

Spando-NTT Representing a Series of Wear-Resistant Sleeves

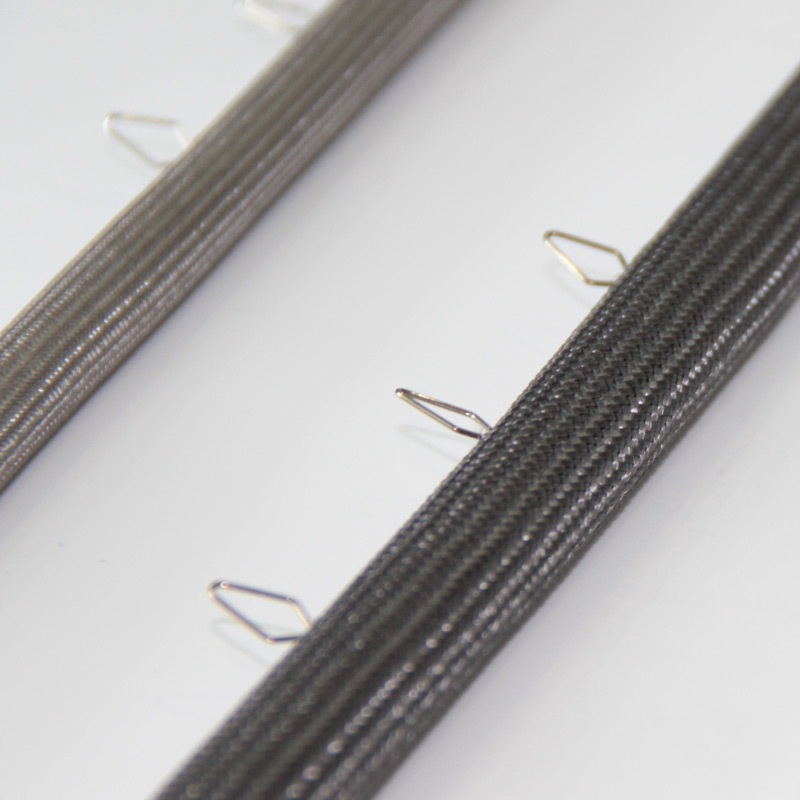

EMI Shielding EMI Shielding Braided Layer by Intertwining Bare or Tinned Copper Wires

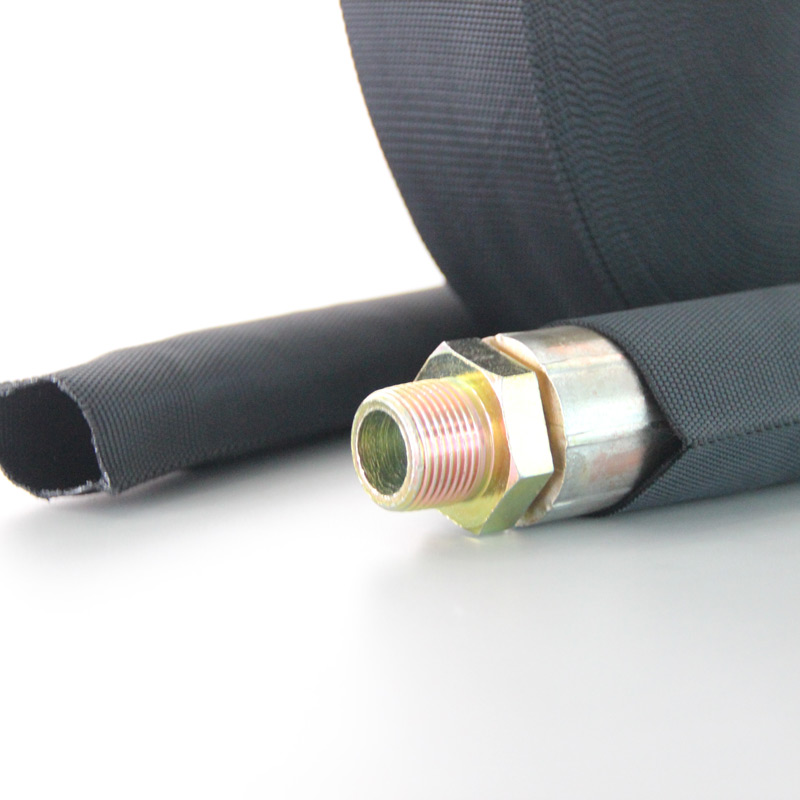

Forteflex for Driving Safety Assurance

Fiberglass knitted soft cord; Fiberglass knitted rope

Spando-flex Represents a Wide Range of Expandable and Wear-Resistant Sleeves

Thermtex Suit Well to Most Equipment

FG-Catalog Fiberglass Strong and Light weight Fiberglass Product

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours